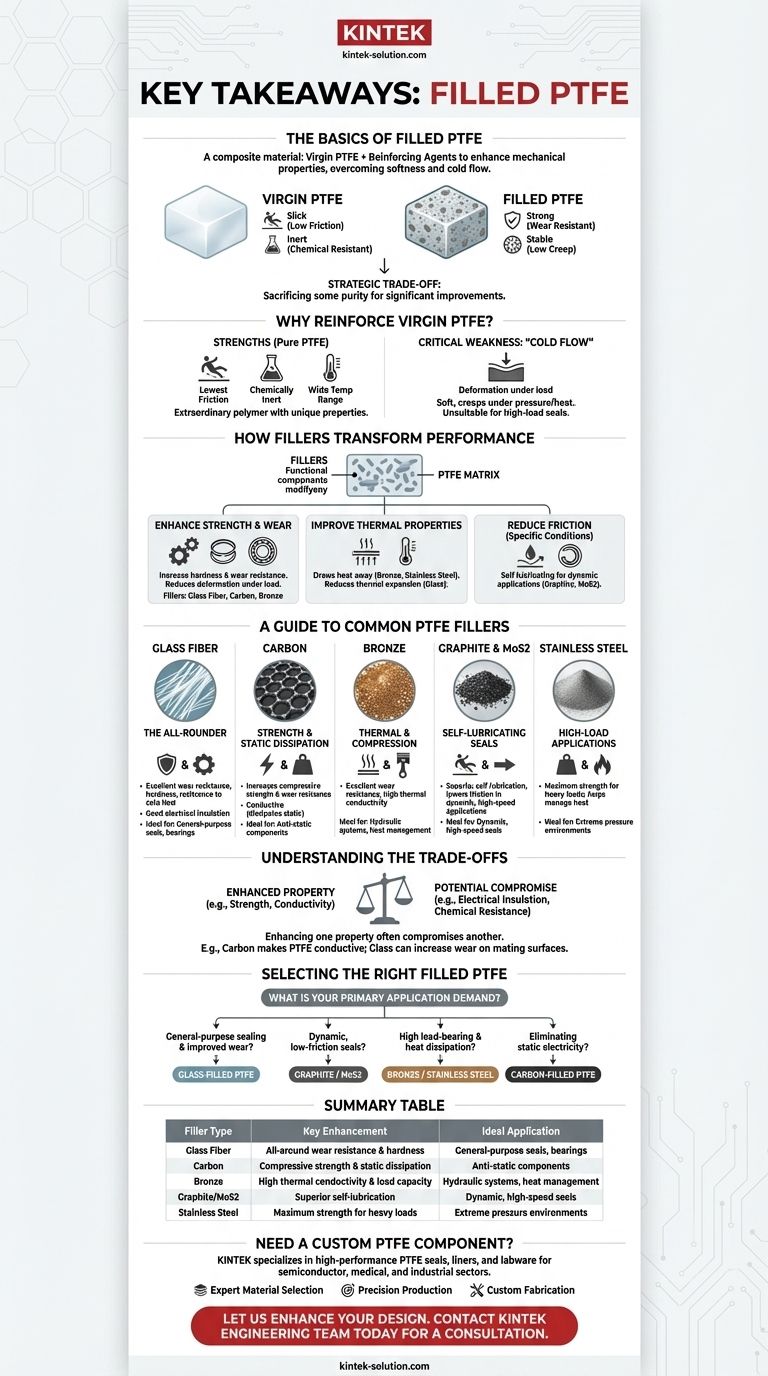

In short, filled PTFE is a composite material created by adding reinforcing agents to virgin Polytetrafluoroethylene (PTFE) to enhance its mechanical properties. This process overcomes PTFE's primary weaknesses—its softness and tendency to deform under pressure—while retaining its signature low friction and chemical inertness, making it suitable for demanding engineering applications.

The central concept is that pure PTFE is an exceptional material with a critical flaw: "cold flow," or deformation under load. Adding fillers like glass, carbon, or bronze is a strategic trade-off, sacrificing some purity to gain significant improvements in wear resistance, strength, and stability.

Why Virgin PTFE Needs Reinforcement

To understand filled PTFE, we must first appreciate the unique characteristics of its base material.

The Strengths of Pure PTFE

Pure PTFE, commonly known by the brand name Teflon, is an extraordinary polymer. It possesses the lowest coefficient of friction of any known solid, making it incredibly slippery.

It is also almost entirely inert, offering outstanding resistance to chemical attack, weathering, and a wide range of temperatures.

The Critical Weakness: Cold Flow

Despite these strengths, PTFE is inherently soft. When subjected to a sustained load, especially at elevated temperatures, it will slowly deform or "creep."

This phenomenon, known as cold flow, makes virgin PTFE unsuitable for applications like high-pressure seals or structural bearings where dimensional stability is critical.

How Fillers Transform PTFE Performance

Fillers are not just additives; they are functional components that fundamentally change how the material behaves under stress.

Enhancing Mechanical Strength and Wear Resistance

The primary reason to add fillers is to increase hardness and resistance to wear. Fillers like glass fiber, carbon, and bronze act as a reinforcing matrix within the soft PTFE, significantly reducing deformation under load.

This improvement makes filled PTFE a superior choice for components like piston rings and bearings that experience constant mechanical stress.

Improving Thermal Properties

PTFE is an insulator, which can be a problem in applications where frictional heat needs to dissipate.

Fillers with higher thermal conductivity, such as bronze and stainless steel, help draw heat away from wear surfaces. Others, like glass, reduce the material's rate of thermal expansion, improving its stability across temperature changes.

Reducing Friction in Specific Conditions

While pure PTFE is already slippery, certain fillers can enhance its performance in dynamic applications.

Graphite and molybdenum disulfide (MoS2) are self-lubricating, making them ideal for dynamic seals where consistent, low friction is paramount. Polyamide is noted for having the lowest friction in non-lubricated conditions.

A Guide to Common PTFE Fillers

The choice of filler directly dictates the material's final properties and its ideal application.

Glass Fiber: The All-Rounder

Glass is the most common filler. It provides an excellent all-around improvement in wear resistance, hardness, and resistance to cold flow. It also maintains good electrical insulation properties, making it highly versatile.

Carbon: For Strength and Static Dissipation

Carbon significantly increases compressive strength and wear resistance. Critically, it also makes the PTFE conductive, which is essential for applications requiring the dissipation of static electricity.

Bronze: For Thermal Conductivity and Compression

Bronze fillers create a composite with excellent wear resistance and high thermal conductivity. This makes it a preferred choice for hydraulic systems and components that need to manage heat.

Graphite & MoS2: For Self-Lubricating Seals

These fillers are chosen specifically for their ability to lower friction in dynamic, high-speed applications. They are often used in combination with other fillers like carbon or glass to achieve a balance of properties.

Stainless Steel: For High-Load Applications

Stainless steel powder increases the material's strength and ability to handle heavy loads. Its thermal conductivity also helps manage heat in demanding environments.

Understanding the Trade-offs

Enhancing one property of PTFE with a filler often means compromising on another. This is the central challenge of material selection.

Impact on Electrical Properties

The most significant trade-off involves electrical performance. While glass-filled PTFE remains a good insulator, carbon-filled PTFE becomes conductive. This makes carbon unsuitable for any application requiring high dielectric strength.

Potential Reduction in Chemical Resistance

While PTFE itself is nearly inert, some fillers are not. Bronze, for example, can be attacked by certain chemicals, slightly reducing the composite's overall chemical compatibility compared to virgin PTFE.

Mating Surface Considerations

Abrasive fillers like glass can increase the wear on softer mating surfaces (e.g., aluminum or brass shafts). This must be considered in the overall system design to prevent premature failure of other components.

Selecting the Right Filled PTFE for Your Application

Your choice should be dictated entirely by the primary demands of the application.

- If your primary focus is general-purpose sealing with improved wear: Glass-filled PTFE is the most common and cost-effective starting point.

- If your primary focus is dynamic, low-friction seals: Choose a compound with graphite or molybdenum disulfide (MoS2) for self-lubricating properties.

- If your primary focus is high load-bearing capacity and heat dissipation: Bronze or stainless steel-filled grades are designed for this purpose.

- If your primary focus is eliminating static electricity: Carbon-filled PTFE is the only suitable choice.

By understanding that filled PTFE is a family of customized materials, you can select the precise compound engineered to solve your specific problem.

Summary Table:

| Filler Type | Key Property Enhancement | Ideal Application |

|---|---|---|

| Glass Fiber | All-around wear resistance & hardness | General-purpose seals, bearings |

| Carbon | Compressive strength & static dissipation | Anti-static components |

| Bronze | High thermal conductivity & load capacity | Hydraulic systems, heat management |

| Graphite/MoS2 | Superior self-lubrication | Dynamic, high-speed seals |

| Stainless Steel | Maximum strength for heavy loads | Extreme pressure environments |

Need a custom PTFE component engineered for your specific demands?

KINTEK specializes in manufacturing high-performance PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical trade-offs in material selection and can help you choose or custom-formulate the perfect filled PTFE compound for your application.

We offer:

- Expert Material Selection: Guidance to balance wear resistance, chemical compatibility, thermal properties, and electrical requirements.

- Precision Production: From prototypes to high-volume orders, ensuring dimensional stability and performance.

- Custom Fabrication: Solutions tailored to overcome challenges like cold flow, friction, and heat dissipation.

Let us enhance your design with the right PTFE composite. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining