In essence, custom Polytetrafluoroethylene (PTFE) parts enhance industrial efficiency by providing exceptionally durable, low-friction components tailored to specific operational challenges. Their unique combination of chemical inertness, temperature resistance, and machinability allows them to operate reliably in harsh environments where other materials would fail, significantly reducing downtime and maintenance costs.

The core advantage is not just PTFE's inherent properties, but the ability to precisely machine it into custom shapes. This transforms a high-performance material into a targeted solution that solves unique industrial problems, maximizing equipment longevity and operational uptime.

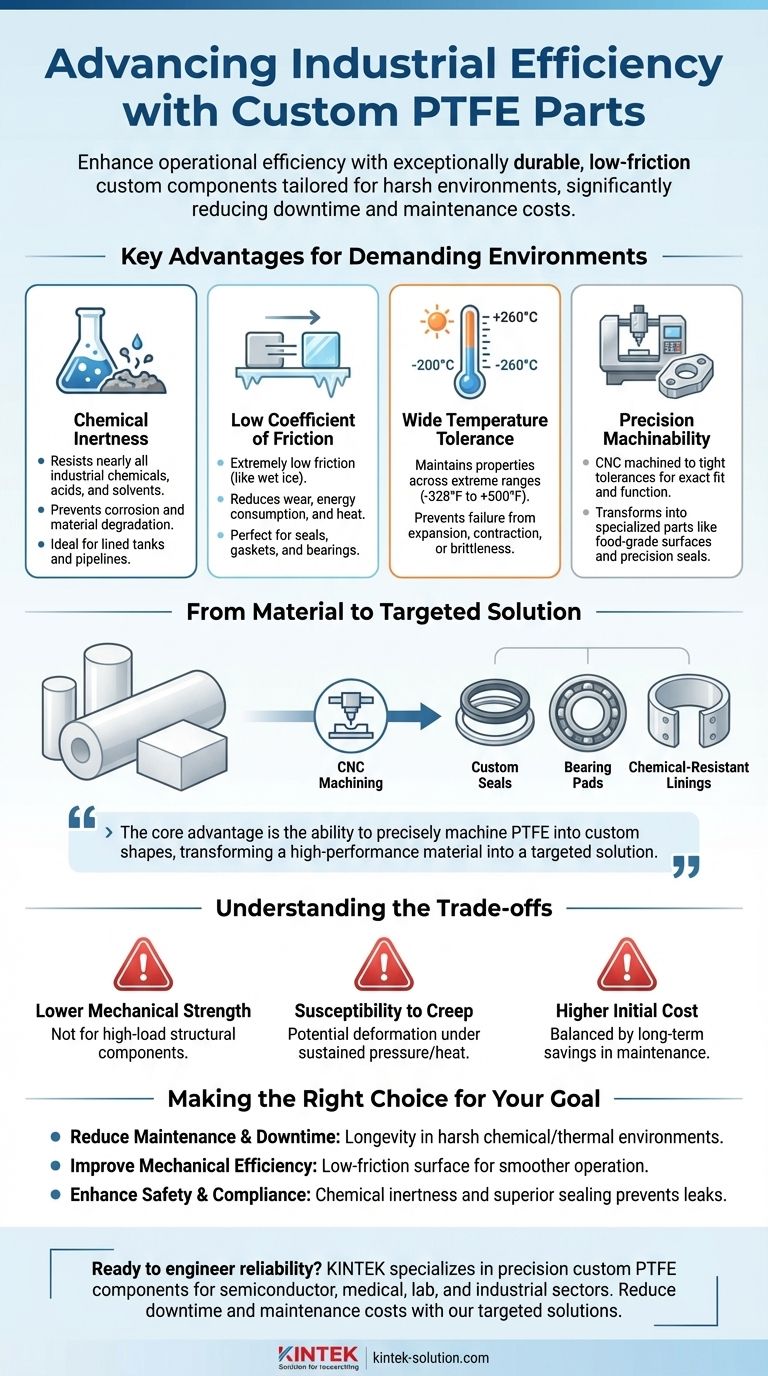

Why PTFE Solves Problems in Demanding Environments

The value of custom PTFE parts stems directly from the material's fundamental characteristics. These properties allow components to withstand conditions that quickly degrade conventional plastics and metals.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents. This prevents corrosion and material degradation.

Custom-machined PTFE-lined tanks and pipelines can handle aggressive chemicals without compromising structural integrity, safeguarding both the equipment and the process workflow.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is critical for moving parts.

This property reduces wear and energy consumption in applications like seals, gaskets, and bearings, leading to longer part life and more efficient mechanical operation.

Wide Temperature Tolerance

PTFE components maintain their properties across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability ensures reliable performance in processes involving extreme heat or cryogenic cold, preventing part failure due to expansion, contraction, or brittleness.

The Power of Precision: From Material to Solution

While the properties of PTFE are impressive, the ability to customize it unlocks its full potential. Standard, off-the-shelf parts cannot solve highly specific engineering challenges.

Machinability for Specific Needs

PTFE is readily machinable with high precision using CNC equipment. This allows for the creation of components with tight tolerances designed for an exact fit and function.

This transforms raw PTFE into specialized parts like food-grade cutting surfaces, precision seals for a specific valve, or chemical-resistant linings molded to a unique tank geometry.

Optimizing Performance in Unique Applications

A custom-fit part performs its function more effectively, directly improving system efficiency.

PTFE bearing pads, for example, can be custom-designed to bear specific structural loads, ensuring silent and smooth movement in large structures. Likewise, custom expansion joints create a perfect seal, reducing airborne pollutants and resource waste.

Understanding the Trade-offs

No material is a universal solution. While PTFE's advantages are significant, it's critical to understand its limitations to apply it correctly.

Relatively Low Mechanical Strength

Compared to metals or high-performance polymers like PEEK, PTFE has lower tensile strength and is less rigid. It is not suitable for high-load structural components that require extreme stiffness.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, PTFE can exhibit "creep" or cold flow. Part design must account for this potential deformation to ensure long-term dimensional stability.

Higher Initial Cost

The raw material and specialized machining for custom PTFE parts can result in a higher upfront cost compared to components made from more common plastics or metals. This cost must be weighed against the long-term savings from reduced maintenance and downtime.

Making the Right Choice for Your Goal

Selecting custom PTFE components should be driven by a clear operational objective.

- If your primary focus is reducing maintenance and downtime: Its longevity in harsh chemical and thermal environments makes it the ideal choice for parts that are difficult or costly to replace.

- If your primary focus is improving mechanical efficiency: Its low-friction surface provides smoother, more reliable operation for bearings, seals, and other dynamic components.

- If your primary focus is safety and compliance: Its chemical inertness and superior sealing capabilities prevent hazardous leaks and can be used in food-grade or sanitary applications.

Ultimately, custom PTFE parts provide a powerful tool for engineering reliability directly into your most demanding industrial processes.

Summary Table:

| Key Advantage | Impact on Industrial Efficiency |

|---|---|

| Chemical Inertness | Resists corrosion, prevents degradation, and safeguards processes. |

| Low Friction | Reduces wear, lowers energy consumption, and extends part life. |

| Wide Temperature Range | Ensures reliable performance in extreme heat or cold, preventing failure. |

| Precision Machinability | Creates exact-fit components that solve unique operational challenges. |

Ready to engineer reliability into your most demanding processes?

KINTEK specializes in manufacturing precision custom PTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. We transform PTFE's superior properties into targeted solutions that reduce your downtime and maintenance costs.

From prototypes to high-volume orders, our custom fabrication ensures a perfect fit for your unique application. Contact KINTEK today to discuss how our PTFE parts can enhance your operational efficiency and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between PTFE and conventional oil seals? Optimize Performance and Cost

- Why are FEP and PTFE encapsulated O-rings used in the food and pharmaceutical industries? Ensure Purity and Compliance

- What are some unique challenges when machining Teflon? Overcome Material Instability for Precision Parts

- How does PTFE Liner help in eliminating stick-slip in cable applications? Achieve Smooth, Reliable Motion

- What are the key differences between machining filled and unfilled PTFE? Optimize Your Process for Performance

- How does the quality of Teflon bearings compare to traditional bearings? Superior Performance in Harsh Environments

- What are the benefits of the low friction and non-stick surface of PTFE gaskets? Enhance Equipment Life and Process Purity

- What happens if standard PTFE is used for both upper and lower members of a slide bearing? Avoid Premature Failure with the Right Design