At first glance, Teflon (PTFE) seems easy to machine due to its softness, but this is deceptive. The unique challenges arise from a combination of properties not found in metals or even other plastics: low thermal conductivity, a high coefficient of thermal expansion, and a tendency to deform under pressure, known as stress creep. These factors make achieving tight tolerances and a clean surface finish exceptionally difficult.

The core challenge in machining Teflon is not cutting the material, but controlling its inherent instability. Success requires a strategy focused on minimizing heat and pressure at every stage, from workholding to the final cut, to prevent the part from deforming unpredictably.

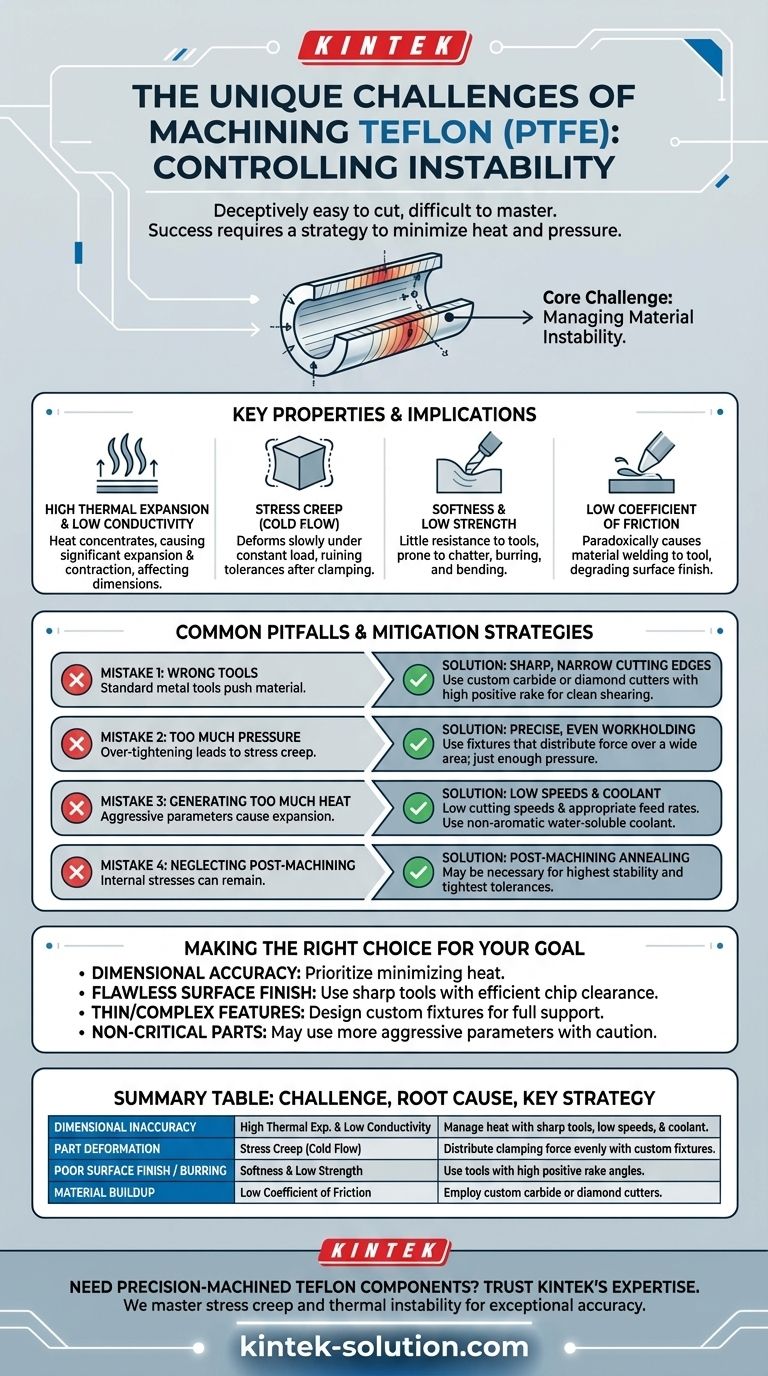

The Root Cause: Managing Material Instability

Unlike metals that are rigid and thermally stable, Teflon is fundamentally unstable during the machining process. Its softness makes it easy to remove material, but this same property makes it highly susceptible to deformation from tool pressure and clamping forces.

The real difficulty lies in managing the material's response to the heat and stress of machining. Without the right approach, parts can easily end up out of tolerance, warped, or covered in burrs.

Key Properties and Their Machining Implications

Understanding four key material properties is critical to diagnosing and solving the challenges of machining Teflon.

High Thermal Expansion & Low Conductivity

Teflon does not dissipate heat well. Heat generated by the cutting tool stays concentrated at the point of contact, causing the material to expand significantly.

When the part cools, it contracts. This constant change in size during the operation makes holding precise dimensions a primary challenge.

Stress Creep (Cold Flow)

Teflon has a tendency to slowly deform over time when under a constant load, even at room temperature. This is known as stress creep or cold flow.

When a part is clamped in a vise, it begins to creep. After machining, once the clamping pressure is released, the part will deform, ruining any tight tolerances that were achieved.

Softness and Low Strength

While softness makes the material easy to cut, it also means it provides little resistance to the cutting tool, leading to the risk of tool chatter.

This softness also makes Teflon prone to burring and can cause the part to deform or bend away from the cutter, especially with thin walls or unbalanced shapes.

Low Coefficient of Friction

Teflon's famous slipperiness can paradoxically cause material to stick or weld to the cutting tool tip. This happens when heat and pressure are high enough to soften the material.

This buildup on the tool edge degrades the surface finish and can throw the part's final dimensions out of specification.

Common Pitfalls and How to Avoid Them

Successfully machining Teflon requires a specific mindset and toolset designed to counteract its inherent properties.

Mistake 1: Using the Wrong Tools

Standard cutting tools used for metals will not work well. Teflon's softness demands extremely sharp, narrow cutting edges to create a clean shearing action rather than pushing the material.

Custom carbide cutters with high positive rake angles and clearance are often necessary to prevent material buildup and ensure clean chip evacuation. For the highest precision, diamond cutters offer superior performance.

Mistake 2: Applying Too Much Pressure

Over-tightening a vise is a common mistake that guarantees failure due to stress creep. Workholding must be precise and apply just enough pressure to secure the part.

Use fixtures that distribute clamping force evenly across a wide surface area. This provides support without creating the localized pressure points that lead to deformation.

Mistake 3: Generating Too Much Heat

Aggressive cutting speeds and feeds that work for other materials will generate excessive heat in Teflon, causing it to expand and ruin tolerances.

Use low cutting speeds and appropriate feed rates. The application of a non-aromatic, water-soluble coolant is also highly recommended to manage heat, improve surface finish, and extend tool life.

Mistake 4: Neglecting Post-Machining Effects

Even with perfect technique, internal stresses can be induced during machining. For parts requiring the highest degree of stability and tightest tolerances, post-machining annealing may be necessary to relieve these stresses.

Making the Right Choice for Your Goal

Your strategy should adapt based on the specific requirements of the finished part.

- If your primary focus is dimensional accuracy: Prioritize minimizing heat by using very sharp tools, low cutting speeds, and an effective coolant.

- If your primary focus is a flawless surface finish: Use tools with sharp, narrow cutting edges and geometries specifically designed for efficient chip clearance.

- If you are working with thin or complex features: Design custom fixtures that support the part fully without applying excessive clamping pressure.

- If your part is non-critical and tolerances are loose: You may be able to use more aggressive parameters, but remain mindful of heat buildup and deformation.

Success in machining Teflon comes not from force, but from a precise and deliberate approach that respects the material's unique and unstable nature.

Summary Table:

| Challenge | Root Cause | Key Mitigation Strategy |

|---|---|---|

| Dimensional Inaccuracy | High thermal expansion & low conductivity | Use sharp tools, low speeds, and coolant to manage heat. |

| Part Deformation (Stress Creep) | Material cold flow under pressure | Design fixtures to distribute clamping force evenly. |

| Poor Surface Finish / Burring | Softness and low strength | Use tools with high positive rake angles for a clean shear. |

| Material Buildup on Tool | Low coefficient of friction | Employ custom carbide or diamond cutters for efficient chip clearance. |

Need Precision-Machined Teflon Components? Trust KINTEK's Expertise.

Machining Teflon to meet exact specifications requires specialized knowledge and equipment. KINTEK manufactures high-quality PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We master the challenges of stress creep and thermal instability to deliver parts with exceptional dimensional accuracy and surface finish.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Let us apply our expertise to your project.

Contact KINTEK today for a quote and see how we can bring stability and precision to your Teflon parts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments