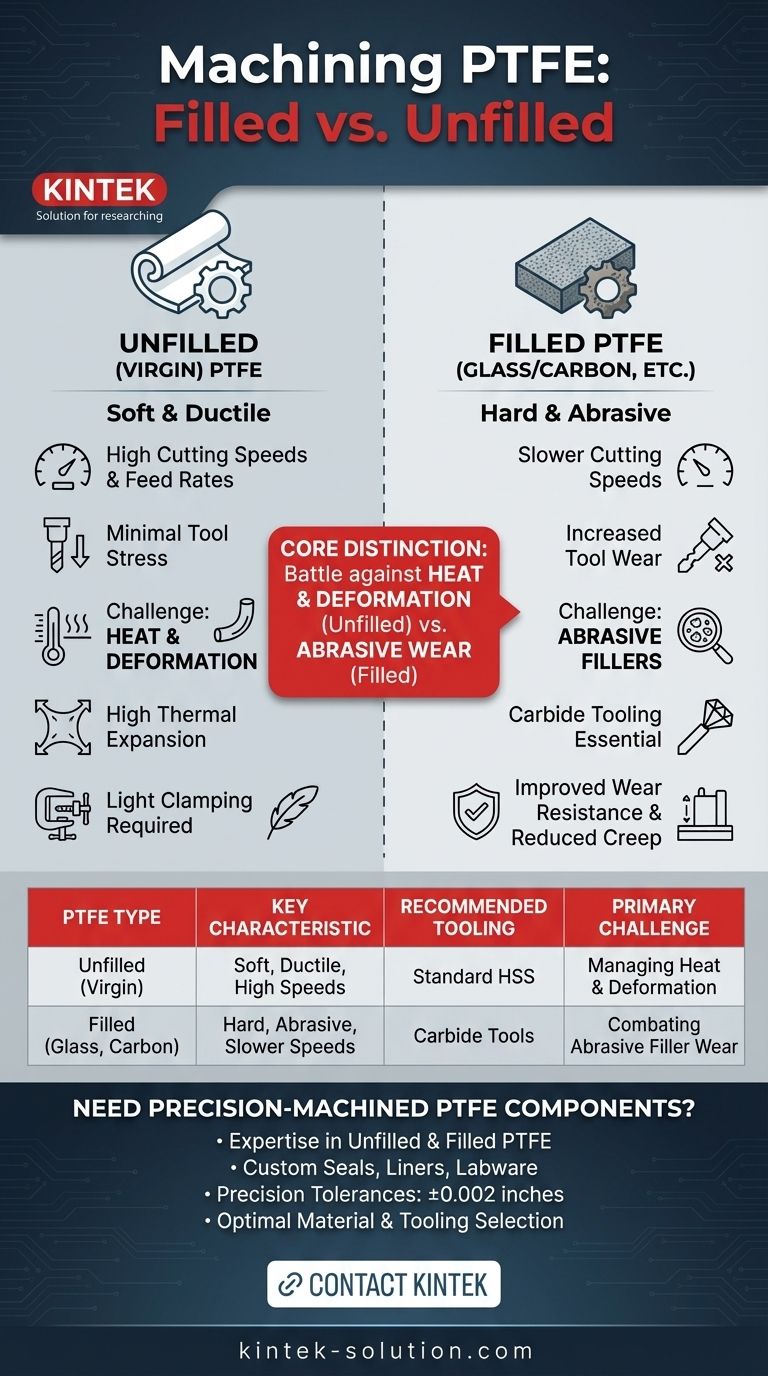

To machine PTFE effectively, you must recognize the fundamental difference between its filled and unfilled variants. Unfilled (virgin) PTFE is soft and ductile, allowing for high cutting speeds with minimal tool wear. In contrast, filled PTFE is harder and more abrasive due to additives like glass or carbon, which necessitates slower speeds, more durable tooling, and careful thermal management to achieve a quality finish.

The core distinction is not just the material's final properties but the machining philosophy required. Machining unfilled PTFE is a battle against heat and deformation due to its softness, while machining filled PTFE is a battle against the abrasive nature of its additives.

Understanding Unfilled (Virgin) PTFE

Unfilled PTFE is the purest form of the material. Its unique properties make it relatively easy to cut but challenging to hold to tight tolerances.

The Advantage of Softness

The inherent softness and ductility of virgin PTFE mean that it places very little stress on cutting tools. This allows for higher cutting speeds and feed rates, which can reduce cycle times.

The Primary Challenge: Heat and Expansion

PTFE has a very high coefficient of thermal expansion. Heat generated during cutting can cause the material to expand significantly, making it difficult to maintain dimensional accuracy. Effective cooling is not just beneficial; it is often essential.

Managing Material Deformation

Because it is so soft, unfilled PTFE can easily be compressed or deformed by excessive clamping pressure in a vise or chuck. A light, even touch is required to hold the workpiece securely without distorting its final shape.

The Impact of Fillers on Machinability

Adding fillers like glass, carbon, or bronze dramatically changes PTFE's mechanical properties, and therefore, how it must be handled on a machine. While these fillers improve wear resistance and reduce creep, they introduce new machining challenges.

Increased Hardness and Abrasiveness

Fillers are, by nature, much harder and more abrasive than the PTFE matrix. This causes cutting tools to wear out much more rapidly than they would with virgin PTFE.

The Necessity for Slower Speeds

To combat the accelerated tool wear caused by abrasive fillers, cutting speeds must be reduced. Pushing the speed too high will quickly dull the cutting edge, leading to a poor surface finish and dimensional inaccuracy.

Specialized Tooling Requirements

Standard high-speed steel (HSS) tools will not last long against filled PTFE. Carbide tools are strongly recommended due to their superior hardness and wear resistance, ensuring both tool longevity and consistent part quality.

Common Pitfalls and Dimensional Stability

Whether working with filled or unfilled PTFE, achieving precision requires an understanding of the material's inherent instability. Forcing it to behave like a metal will lead to failure.

The Challenge of Thermal Expansion

This is the most critical factor. A part measured at one temperature may be out of tolerance at another. Using coolant and allowing the material to normalize to room temperature before final measurements are key to achieving accuracy.

The Risk of Stress Creep

PTFE is prone to "stress creep," meaning it can slowly deform over time when under pressure. This is why light clamping pressure is so crucial. Over-tightening can induce internal stresses that cause the part to warp after it has been machined.

Achieving and Holding Tight Tolerances

Despite these challenges, skilled machinists can hold tolerances within ±0.002 inches. This requires sharp tools, optimized speeds and feeds, excellent heat management, and an awareness of the material's tendency to move.

Making the Right Machining Choice

Your approach should be dictated by the material variant and your project's end goal.

- If your primary focus is high-speed production of non-critical components: Unfilled PTFE is ideal, allowing for faster cycle times and use of standard tooling.

- If your part requires superior wear resistance and thermal stability: Filled PTFE is necessary, but you must budget for slower machining speeds and the cost of carbide tooling.

- If your primary focus is achieving the highest possible precision: Your strategy must revolve around mitigating thermal expansion and deformation, regardless of whether the material is filled or unfilled.

By respecting the unique properties of each PTFE variant, you can successfully machine this versatile material to meet precise engineering requirements.

Summary Table:

| PTFE Type | Key Machining Characteristic | Recommended Tooling | Primary Challenge |

|---|---|---|---|

| Unfilled (Virgin) | Soft, ductile, high cutting speeds | Standard HSS tools | Managing heat and material deformation |

| Filled (Glass, Carbon, etc.) | Hard, abrasive, slower speeds required | Carbide tools | Combating abrasive filler wear |

Need Precision-Machined PTFE Components?

Whether your project requires the chemical purity of unfilled PTFE or the enhanced wear resistance of filled PTFE, KINTEK has the expertise to deliver. We specialize in custom fabrication of PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries.

We ensure precision by:

- Selecting the optimal material and tooling for your application.

- Meticulously managing heat and clamping pressures to maintain dimensional stability.

- Holding tolerances as tight as ±0.002 inches.

From prototypes to high-volume orders, let us handle the complexities of machining PTFE. Contact our engineering team today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials