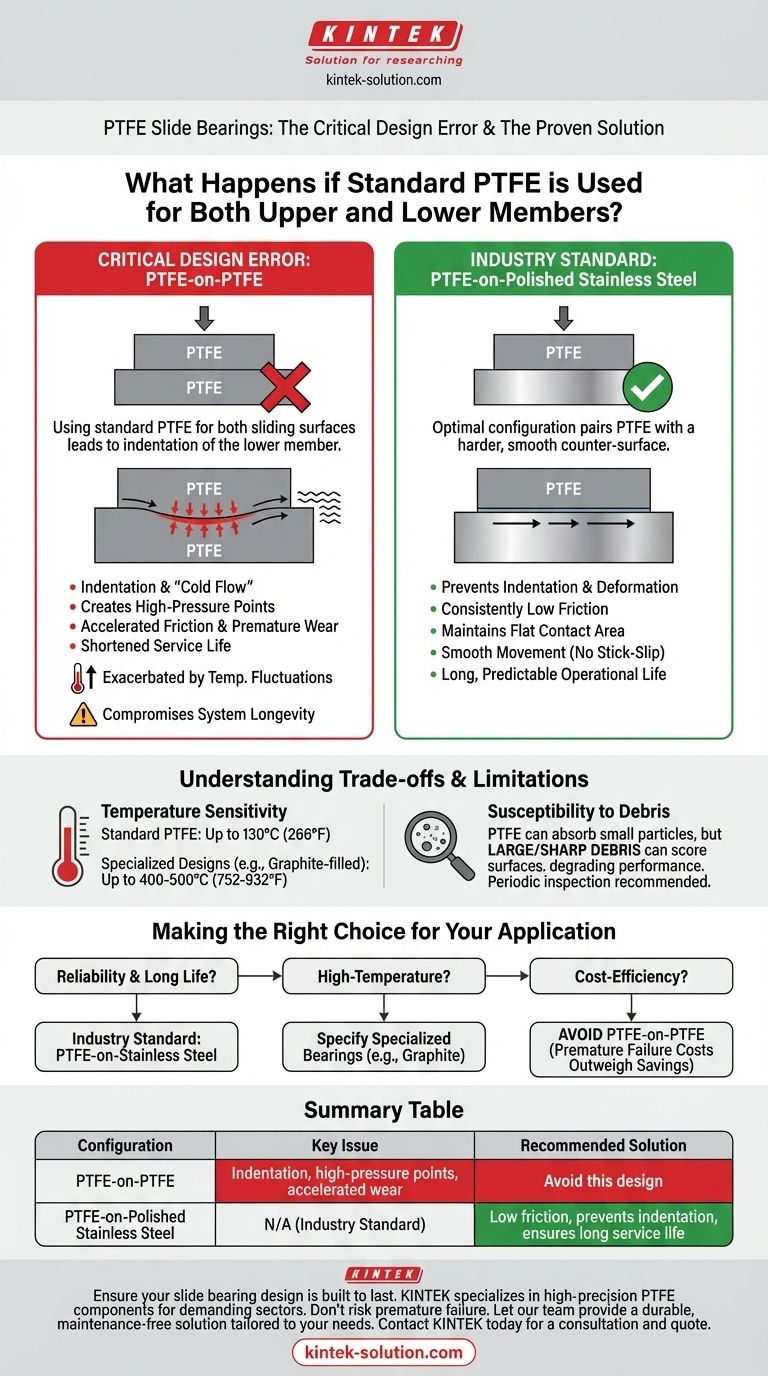

Using standard PTFE for both sliding surfaces is a critical design error. This configuration leads to indentation of the lower PTFE member over time, especially under load or with temperature changes. This deformation creates high-pressure points that cause accelerated friction and premature wear, undermining the bearing's primary function.

A PTFE-on-PTFE slide bearing design compromises the system's longevity. The optimal and standard configuration pairs a PTFE surface with a harder, smooth counter-surface, like polished stainless steel, to ensure consistently low friction and prevent premature failure.

The Problem with PTFE-on-PTFE Contact

Pairing two identical, relatively soft materials in a high-load sliding application introduces a fundamental point of failure. The properties that make PTFE an excellent bearing surface are compromised without a proper counter-surface.

Indentation and Pressure Points

When PTFE is used for both the upper and lower members, the lower surface is susceptible to deformation.

Over time, the consistent load path causes the lower member to indent or "cold flow." This creates a depression that the upper member must constantly climb out of during movement.

This effect is exacerbated by temperature fluctuations, which can alter the dimensional stability of the PTFE and accelerate the indentation process.

Premature Wear and Failure

The high-pressure points created by indentation dramatically increase localized friction.

This leads to unnecessary stress and a rapid breakdown of the PTFE material, resulting in premature wear and a shortened service life for the entire bearing assembly.

The Industry Standard: A Superior Configuration

To leverage the unique benefits of PTFE, it must be paired with a material that resists the failure modes described above. This is why the industry has standardized on a specific material combination.

The Role of Polished Stainless Steel

The ideal counter-surface for a PTFE slide bearing is polished stainless steel.

Its hardness prevents the indentation and deformation that occurs with a PTFE-on-PTFE setup. Its smooth, polished surface ensures the lowest possible coefficient of friction when sliding against the PTFE.

How This Combination Maximizes Performance

By pairing PTFE with a hard, smooth partner, you maintain a consistent, flat contact area.

This allows the bearing to function as intended, providing smooth movement without the dangerous stick-slip phenomenon and ensuring a long, predictable operational life.

Understanding the Trade-offs and Limitations

While a correctly designed PTFE bearing is highly effective, it's important to recognize its operational boundaries to ensure reliability.

Temperature Sensitivity

Standard PTFE configurations are typically rated for continuous service up to 130°C (266°F).

For higher-temperature applications, specialized designs such as recessed 5mm PTFE (up to 200°C / 392°F) or graphite-filled bearings (up to 400-500°C / 752-932°F) are required.

Susceptibility to Debris

PTFE's ability to absorb small dirt particles is an advantage, but it is not invulnerable.

While the bearings are essentially maintenance-free, large or sharp debris caught between the sliding surfaces can score the PTFE or the steel, degrading performance. Periodic inspection to ensure the interface is clear is good practice in harsh environments.

Making the Right Choice for Your Application

Selecting the correct material combination is not a matter of preference; it is fundamental to the bearing's function and longevity.

- If your primary focus is reliability and long service life: Always use the industry-standard configuration of PTFE sliding against a polished stainless steel counter-surface.

- If your primary focus is high-temperature operation: Specify a bearing designed for that environment, which may involve recessed PTFE or a graphite sliding material.

- If your primary focus is cost-efficiency: Avoid the PTFE-on-PTFE design, as the cost of premature failure and replacement far outweighs any perceived initial savings.

Properly specifying your slide bearing materials is the most critical step in ensuring a durable, maintenance-free, and effective solution.

Summary Table:

| Configuration | Key Issue | Recommended Solution |

|---|---|---|

| PTFE-on-PTFE | Indentation, high-pressure points, accelerated wear, premature failure | Avoid this design |

| PTFE-on-Polished Stainless Steel | N/A (Industry Standard) | Provides low friction, prevents indentation, ensures long service life |

Ensure your slide bearing design is built to last.

KINTEK specializes in manufacturing high-precision PTFE components, including seals and custom bearing surfaces, for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science and custom fabrication ensures your slide bearings are paired with the optimal counter-surface for maximum performance and longevity.

Don't risk premature failure. Let our team provide a durable, maintenance-free solution tailored to your specific load, temperature, and environmental requirements—from prototype to high-volume production.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers