At its core, PTFE piston rings are indispensable in applications where traditional lubrication is either impossible or undesirable. They are most commonly found in oil-free compressors, pneumatic systems, and machinery handling corrosive chemicals, with significant use in the automotive, food processing, and pharmaceutical industries.

The defining advantage of a PTFE piston ring is its self-lubricating nature and chemical inertness. This allows it to create a reliable seal in environments that would destroy traditional lubricated metal rings, such as in oil-free air compressors or chemical pumps.

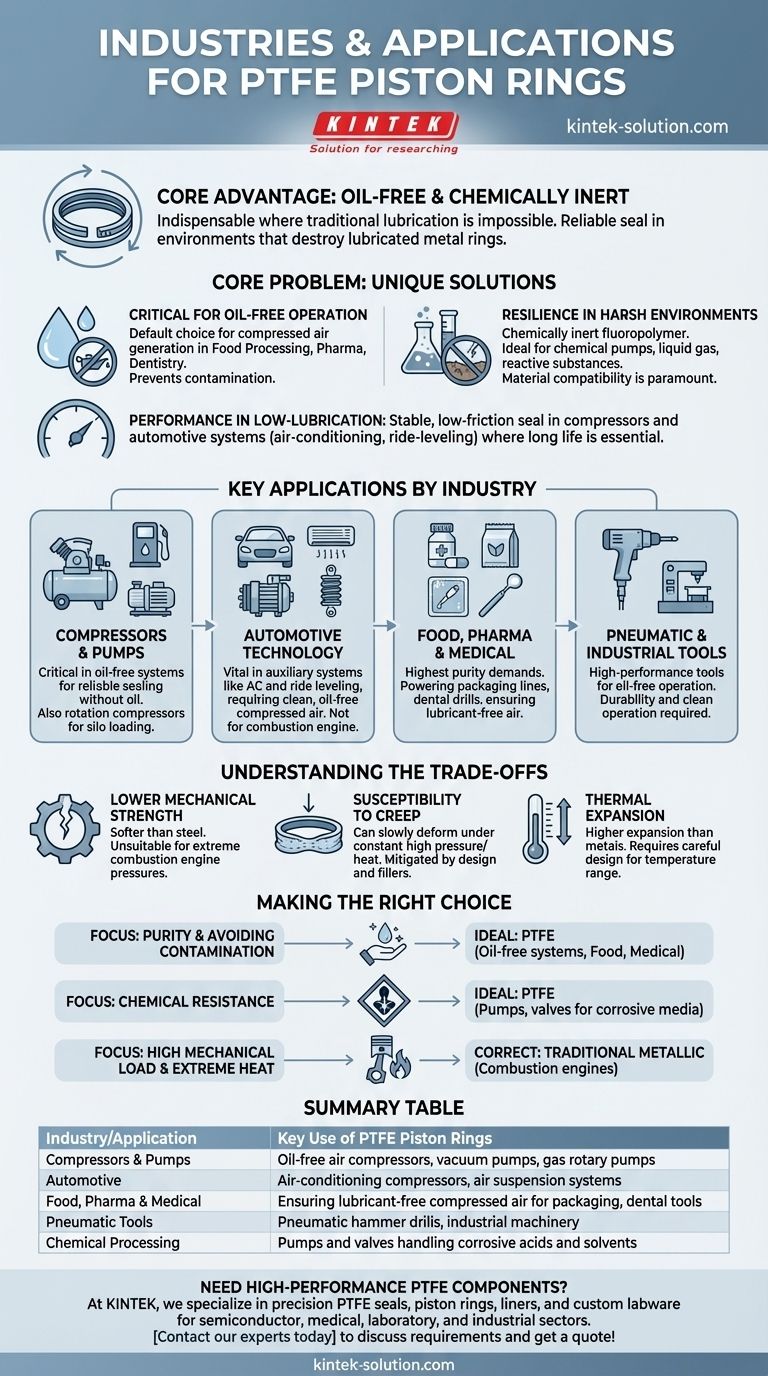

The Core Problem PTFE Piston Rings Solve

To understand where PTFE piston rings are used, we must first understand the problems they are uniquely equipped to handle. Their selection is almost always driven by the need to operate without external lubrication or in chemically aggressive environments.

The Critical Need for Oil-Free Operation

Many industries cannot tolerate even trace amounts of oil lubricants in their processes. This contamination risk is unacceptable in sectors like food processing, pharmaceuticals, and dentistry.

PTFE's extremely low coefficient of friction allows it to function as a self-lubricating seal. This makes it the default choice for oil-free compressed air generation, ensuring the final product remains pure.

Resilience in Harsh Chemical Environments

Standard piston rings made of metal would quickly corrode and fail when exposed to aggressive acids, solvents, or other reactive substances.

PTFE is a fluoropolymer known for being chemically inert to most substances. This makes its rings ideal for use in chemical processing equipment, liquid gas pumps, and other applications where material compatibility is paramount.

Performance in Low-Lubrication Systems

Even in applications that aren't strictly "oil-free," PTFE excels where lubrication is minimal or inconsistent. This is common in certain types of compressors and automotive systems.

These rings provide a stable, low-friction seal in compressors operating under low-lube conditions, as well as in automotive applications like air-conditioning and ride-leveling systems where long life with minimal maintenance is essential.

Key Applications by Industry

The unique properties of PTFE lead to its adoption across a wide and diverse range of specific applications.

Compressors and Pumps

This is the largest category of use. PTFE rings are critical components in wobble piston compressors, gas rotary pumps, and vacuum pumps where reliable sealing without oil is the primary goal. They are also used in rotation compressors for tasks like silo loading and unloading.

Automotive Technology

Within the automotive sector, PTFE piston rings are not used in the engine's combustion chamber but are vital in auxiliary systems. They are commonly found in air-conditioning compressors and air suspension systems (ride leveling), which require clean, oil-free compressed air.

Food, Pharma, and Medical

These industries demand the highest levels of purity. PTFE rings are used in the compressors that power everything from food packaging lines to dental drills, guaranteeing that the compressed air used is free of lubricant contaminants.

Pneumatic and Industrial Tools

High-performance tools also benefit from oil-free operation. PTFE piston rings can be found in equipment like pneumatic hammer drills and other industrial machinery where durability and clean operation are required.

Understanding the Trade-offs

While incredibly versatile, PTFE is not a universal solution. Its material properties introduce trade-offs that make it unsuitable for certain high-load applications.

Lower Mechanical Strength

Compared to steel or cast iron rings, PTFE is a much softer material. It cannot withstand the extreme pressures and mechanical stresses found inside an internal combustion engine, which is why you will not find PTFE piston rings used there.

Susceptibility to Creep

Under constant high pressure and temperature, PTFE can be subject to "creep" or cold flow, meaning it can slowly deform over time. Ring design and the use of fillers in the PTFE material are engineered to mitigate this, but it remains a consideration compared to the rigidity of metal.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. Engineers must account for this during design to ensure the ring maintains a proper seal across the full operating temperature range of the device without becoming too tight or too loose.

Making the Right Choice for Your Application

Selecting the right piston ring material depends entirely on the operational environment and performance requirements.

- If your primary focus is purity and avoiding contamination: PTFE is the ideal choice for any oil-free system, especially in food, medical, or pharmaceutical applications.

- If your primary focus is chemical resistance: PTFE's inertness makes it the superior option for pumps, valves, and compressors handling corrosive media.

- If your primary focus is high mechanical load and extreme heat: A traditional metallic piston ring is the necessary and correct choice, especially for combustion engines.

Ultimately, choosing a PTFE piston ring is a strategic decision to prioritize clean operation and chemical stability in systems where traditional lubrication is not an option.

Summary Table:

| Industry/Application | Key Use of PTFE Piston Rings |

|---|---|

| Compressors & Pumps | Oil-free air compressors, vacuum pumps, gas rotary pumps |

| Automotive | Air-conditioning compressors, air suspension systems |

| Food, Pharma & Medical | Ensuring lubricant-free compressed air for packaging, dental tools |

| Pneumatic Tools | Pneumatic hammer drills, industrial machinery |

| Chemical Processing | Pumps and valves handling corrosive acids and solvents |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in manufacturing precision PTFE seals, piston rings, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our custom fabrication ensures your equipment operates reliably in oil-free or chemically aggressive environments.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the properties of PTFE encapsulated O-rings? Superior Sealing for Harsh Environments

- What is a PTFE gasket and what are its primary properties? Unlock Superior Chemical and Thermal Sealing

- Why is environmental control critical for PTFE machining? Master Dimensional Stability & Surface Finish

- How are PTFE gaskets used in the petroleum and chemical industry? Ensure Leak-Proof Sealing in Harsh Environments

- What types of products are typically made through PTFE paste extrusion? High-Performance Tubing, Hoses & Wire Insulation

- How can anti-stick coatings benefit PTFE gasket maintenance? Reduce Downtime and Protect Equipment

- How do PTFE gaskets perform under extreme temperatures? Unlock Reliable Sealing from -200°C to +260°C

- What is the typical temperature range for PTFE diaphragms? Key Factors for Optimal Performance