Environmental control is critical for PTFE machining because the material possesses an extremely high coefficient of thermal expansion. This means even minor temperature fluctuations cause it to expand or contract significantly, directly compromising the dimensional accuracy and surface finish of the final component. A stable thermal environment is the foundation for achieving tight tolerances.

PTFE's unique properties—its softness and extreme sensitivity to heat—make it notoriously difficult to machine accurately. Success depends on a holistic control strategy that manages not just ambient room temperature, but also localized heat from cutting, mechanical pressures, and airborne contaminants.

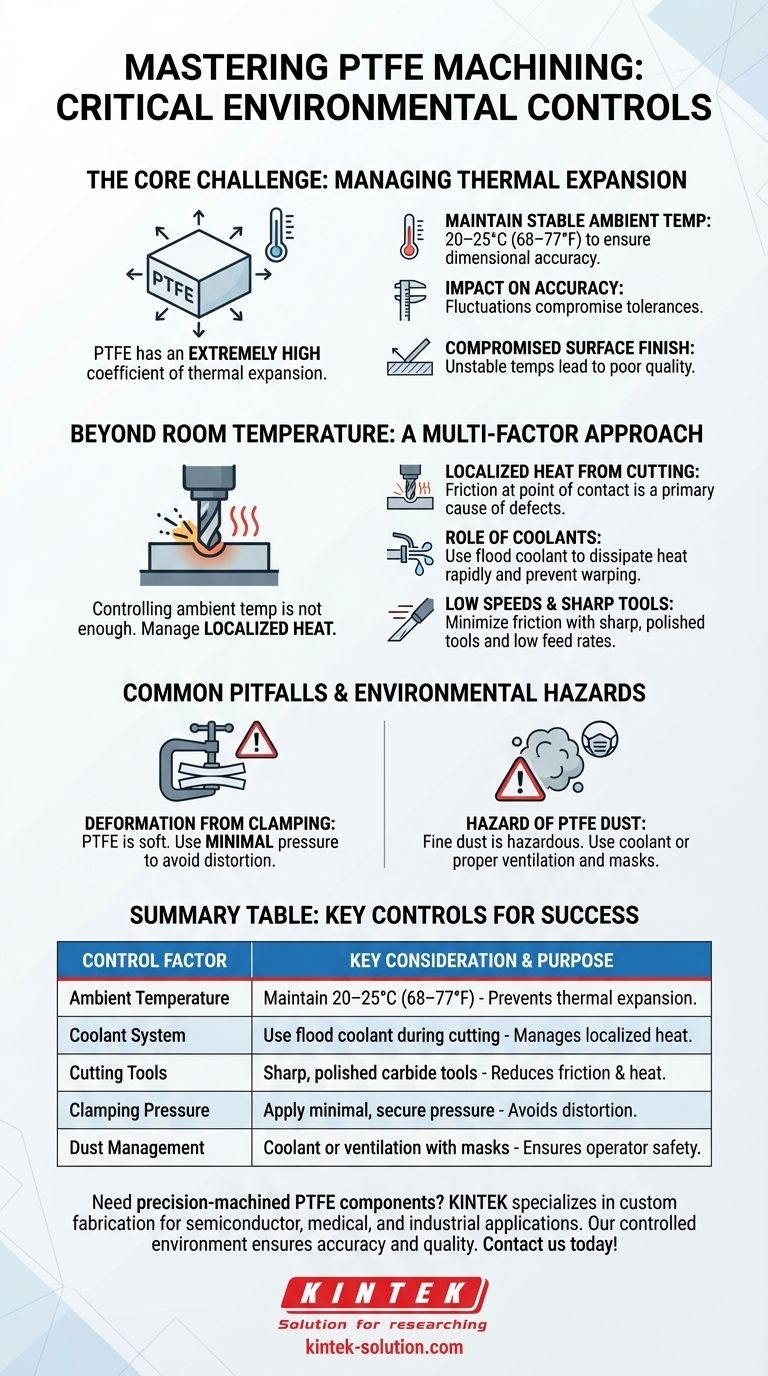

The Core Challenge: Managing Thermal Expansion

Polytetrafluoroethylene (PTFE) behaves very differently from metals and most other plastics. Its thermal instability is the primary obstacle to overcome for precision machining.

PTFE's High Thermal Coefficient

Unlike materials like aluminum or steel, PTFE expands and contracts dramatically with changes in temperature. This property must be accounted for in every step of the machining process, from initial setup to final inspection.

The Impact on Dimensional Accuracy

A part measured at one temperature may be out of tolerance at another. Maintaining a stable and consistent room temperature, ideally between 20–25°C (68–77°F), is essential to ensure that the part's dimensions remain predictable.

Compromised Surface Finishes

Inconsistent thermal expansion can also affect the quality of the cut, leading to a poor surface finish. This is especially critical when machining parts with thin walls or complex geometries that are more susceptible to minor variations.

Beyond Room Temperature: A Multi-Factor Approach

Controlling the ambient air temperature is only the first step. The heat generated during the machining process itself has an even more immediate and localized effect.

Localized Heat from Cutting

The friction between the cutting tool and the PTFE workpiece generates significant heat directly at the point of contact. This localized heating is a primary cause of machining defects.

The Role of Coolants

An effective cooling system is non-negotiable. Using a flood coolant dissipates heat rapidly, preventing the material from overheating, warping, or deforming during the cut.

Low Speeds and Sharp Tools

To minimize heat generation in the first place, it is crucial to use very sharp tools with polished surfaces. Combining this with low cutting speeds and feed rates reduces friction and keeps the material stable.

Common Pitfalls and Environmental Hazards

A successful outcome requires anticipating and mitigating the physical and safety-related challenges inherent to machining PTFE.

Deformation from Clamping Pressure

PTFE is a very soft material with low compressive strength. Excessive clamping pressure in a vise or fixture will easily distort or crush the part before a single cut is made. Fixturing must be secure but apply minimal pressure.

Warping from Internal Stresses

Uneven or rapid heating and cooling can introduce internal stresses into the material. This can cause the finished component to warp or move out of tolerance hours or even days after machining is complete.

The Hazard of PTFE Dust

The machining process creates fine PTFE dust. This micro dust is hazardous if inhaled. Therefore, a critical aspect of environmental control is safety—either machining under a flood coolant to contain the particles or ensuring the area is well-ventilated and operators wear appropriate masks.

Key Controls for Successful PTFE Machining

To achieve consistent, high-quality results with PTFE, implement the following controls based on your project's demands.

- If your primary focus is tight dimensional tolerance: Maintain a stable ambient temperature between 20–25°C (68–77°F) and use a flood coolant system to manage localized heat.

- If your primary focus is excellent surface finish: Use extremely sharp, polished carbide tools with low cutting speeds and feed rates to prevent material tearing and heat buildup.

- If your primary focus is part integrity and safety: Employ minimal clamping pressure to avoid distortion and always use coolant or proper ventilation to manage hazardous dust.

Mastering the machining environment is the definitive factor in transforming PTFE from a challenging material into a predictable one.

Summary Table:

| Control Factor | Key Consideration | Purpose |

|---|---|---|

| Ambient Temperature | Maintain 20–25°C (68–77°F) | Prevents thermal expansion/contraction |

| Coolant System | Use flood coolant during cutting | Manages localized heat from friction |

| Cutting Tools | Sharp, polished carbide tools | Reduces friction and heat generation |

| Clamping Pressure | Apply minimal, secure pressure | Avoids part distortion or crushing |

| Dust Management | Coolant or ventilation with masks | Ensures operator safety from PTFE dust |

Need precision-machined PTFE components that meet strict tolerances? KINTEK specializes in custom PTFE fabrication for semiconductor, medical, laboratory, and industrial applications. Our controlled machining environment ensures dimensional accuracy, superior surface finishes, and part integrity—from prototypes to high-volume orders. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments