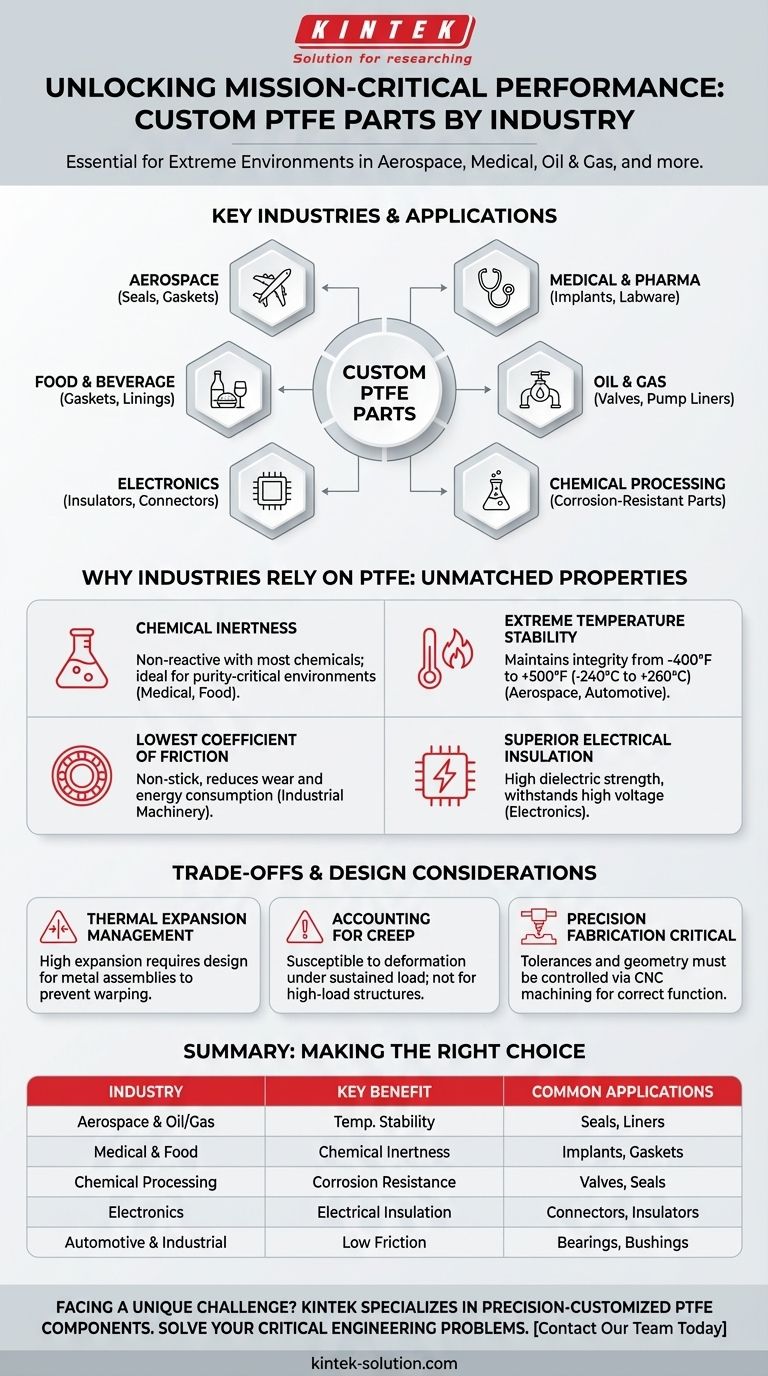

In the most demanding operational environments, custom Polytetrafluoroethylene (PTFE) parts are mission-critical. Industries that benefit most include aerospace, medical and pharmaceutical, oil and gas, chemical processing, electronics, and food and beverage. These sectors depend on custom-fabricated PTFE for its unique ability to withstand extreme conditions where other materials would fail.

The true value of custom PTFE isn't its use in any single industry, but its role as a problem-solver in applications where a unique combination of chemical inertness, temperature resistance, low friction, and electrical insulation is non-negotiable.

Why These Industries Rely on Custom PTFE

The widespread adoption of PTFE is not accidental. It stems from a specific set of material properties that directly solve the core challenges faced by high-stakes industries. The ability to machine this material to precise specifications is what unlocks its full potential.

Unmatched Chemical Inertness

PTFE is almost completely inert, meaning it does not react with most chemicals. This makes it an ideal material for environments where purity is paramount.

Industries like medical, pharmaceutical, and food and beverage use custom PTFE for components like gaskets, seals, and linings. Because it won't contaminate the substances it touches, it ensures product safety and integrity.

In chemical processing and laboratory equipment, PTFE's resistance to corrosive acids and bases prevents degradation and equipment failure.

Extreme Temperature Stability

PTFE components maintain their structural integrity and performance characteristics across a wide temperature range, typically up to 500°F (260°C).

This thermal stability is critical in aerospace, where parts are exposed to drastic temperature fluctuations. It's also vital in automotive applications, such as gaskets and seals near engines, and in oil and gas processing.

The Lowest Coefficient of Friction

Known for its non-stick properties, PTFE has one of the lowest coefficients of friction of any solid material. This makes it a superior material for reducing wear and energy consumption in moving parts.

This is essential for industrial machinery and automotive applications, where PTFE is used for high-performance bearings, bushings, and seals in pumps, conveyors, and steering columns.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

This property makes it indispensable in the electronics industry. Custom-machined PTFE is used for high-frequency insulators, connectors, and enclosures that protect sensitive electronic components.

Understanding the Trade-offs and Design Considerations

While incredibly versatile, PTFE is not a universal solution. Effective implementation requires a clear understanding of its mechanical limitations and precise engineering. Failing to account for these factors is a common point of failure.

Managing Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it expands and contracts significantly with temperature changes.

Designs must account for this movement, especially when a PTFE part is fitted into a metal assembly, to prevent stress, warping, or seal failure.

Accounting for Compressive Strength and Creep

PTFE is a relatively soft material and can be susceptible to "creep," or deformation under a sustained load.

It is not suitable for high-load structural applications. Its strength lies in its surface properties and stability, not its raw mechanical power. Custom designs often use PTFE as a liner or coating on a stronger metal component.

The Critical Role of Precision Fabrication

The benefits of PTFE are only realized when the part is fabricated to the correct specifications.

Factors like tolerances, surface finish, and part geometry must be precisely controlled via CNC machining. This ensures components like seals, valves, and implants function exactly as intended within their operational environment.

Making the Right Choice for Your Application

To determine if custom PTFE is the right fit, align your primary challenge with the material's core strengths.

- If your primary focus is purity and non-contamination: PTFE is an industry standard for medical, food, and laboratory applications where inertness is required.

- If your primary focus is performance in harsh environments: PTFE's resistance to extreme temperatures and corrosive chemicals makes it ideal for aerospace, oil and gas, and chemical processing.

- If your primary focus is reducing friction and wear: Its low-friction surface is a key advantage for creating durable seals, bearings, and bushings in automotive and industrial machinery.

- If your primary focus is electrical insulation: PTFE is one of the best materials available for high-frequency and high-voltage electronic components.

Understanding these core strengths allows you to leverage custom PTFE as a targeted solution for your most critical engineering challenges.

Summary Table:

| Industry | Key PTFE Benefit | Common Applications |

|---|---|---|

| Aerospace & Oil & Gas | Extreme Temperature Stability | Seals, gaskets, liners |

| Medical & Pharmaceutical | Chemical Inertness & Purity | Seals, labware, implants |

| Chemical Processing | Chemical Resistance | Valves, pump liners, seals |

| Electronics | Superior Electrical Insulation | Connectors, insulators, enclosures |

| Food & Beverage | Non-contamination & Purity | Seals, gaskets, linings |

| Automotive & Industrial | Low Friction & Wear Resistance | Bearings, bushings, seals |

Facing a unique material challenge in a demanding environment?

KINTEK specializes in precision-customized PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We leverage our expertise in CNC machining to deliver parts that meet your exact specifications for chemical resistance, thermal stability, and electrical insulation—from initial prototypes to full-scale production runs.

Let us help you solve your most critical engineering problems. Contact our team today to discuss your custom PTFE requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials