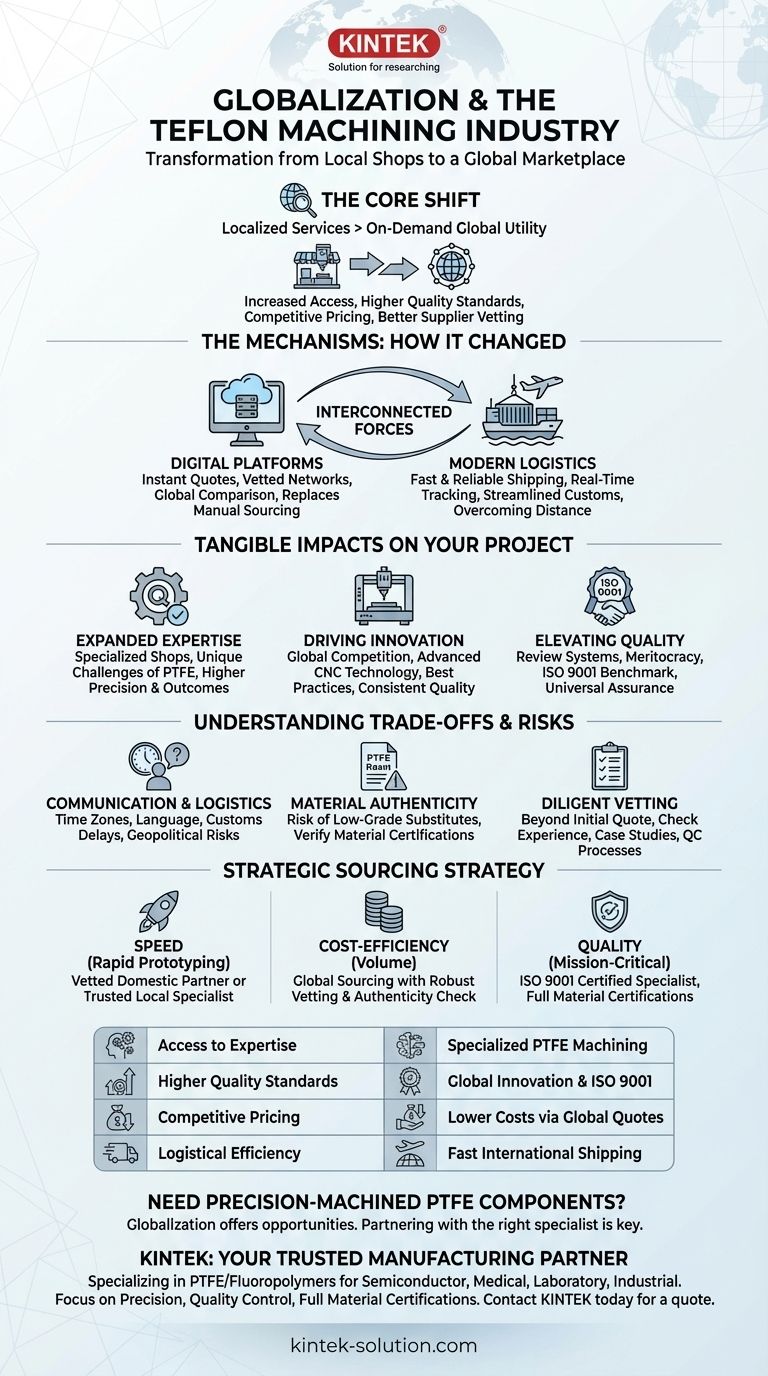

In short, globalization has fundamentally reshaped the Teflon machining industry. It has moved the process from a network of local machine shops into a highly competitive global marketplace, driven by digital platforms and sophisticated logistics. This shift has increased access to specialized expertise, driven up quality standards, and created more options for engineers and product designers than ever before.

The core effect of globalization is the transformation of custom Teflon machining from a localized service into an on-demand global utility. This provides unprecedented access and competitive pricing, but it also places a greater emphasis on diligent supplier vetting and supply chain management.

The Mechanisms: How Globalization Changed the Game

The transformation of the Teflon machining industry didn't happen in a vacuum. It was enabled by two powerful, interconnected forces: digital manufacturing platforms and modern international logistics.

The Rise of Digital Manufacturing Platforms

Digital platforms act as intermediaries, connecting customers who need custom parts with a vetted, global network of machine shops. This model fundamentally changes the procurement process.

By uploading a CAD file, you can receive quotes from multiple suppliers almost instantly, comparing costs and lead times from shops around the world. This replaces the slow, manual process of finding and vetting local suppliers one by one.

The Efficiency of Global Logistics

Simultaneously, international logistics networks have become incredibly fast, reliable, and transparent.

Companies can now ship precision components from a facility on another continent to their assembly line in a matter of days. Real-time tracking and streamlined customs processes have removed the distance barrier that once made international sourcing impractical for all but the largest corporations.

Tangible Impacts on Your Project

These globalizing forces have direct and practical consequences when you need to source custom-machined Teflon (PTFE) components.

Expanded Access to Niche Expertise

Teflon is notoriously difficult to machine correctly due to its softness, high thermal expansion, and tendency to deform. Globalization means you are no longer limited to the expertise in your immediate geographic area.

You can now easily connect with a shop that specializes in the unique challenges of machining fluoropolymers, ensuring higher precision and better outcomes for your parts, regardless of that shop's physical location.

Driving Innovation in Machining Techniques

Global competition creates immense pressure to improve. To win business, machine shops must invest in the latest CNC technology, specialized tooling designed for soft plastics, and advanced quality control methods.

This competitive environment accelerates the adoption of best practices, leading to higher-quality, more consistent parts for the end customer.

Elevating Universal Quality Standards

In a global marketplace, reputation is paramount. Digital platforms often use a review and rating system, creating a meritocracy where quality and reliability are rewarded.

Furthermore, international standards like ISO 9001 become a crucial benchmark, providing a universal language for quality assurance that allows you to confidently vet a supplier thousands of miles away.

Understanding the Trade-offs and Risks

While the benefits are significant, a globalized supply chain introduces new complexities and potential pitfalls that require careful management.

Navigating Communication and Logistics

Working across different time zones, languages, and business cultures can introduce friction and delays. Clear, concise communication is essential.

Longer shipping routes also mean your parts are in transit longer, increasing the risk of delays due to customs, weather, or geopolitical disruptions.

Verifying Material Authenticity

A primary risk in global sourcing is ensuring you receive parts made from genuine, high-quality PTFE resin (like Teflon™ from Chemours) rather than a cheaper, lower-grade substitute.

Without proper verification, you may receive a part that fails to meet the required chemical resistance, temperature rating, or dielectric properties for your application. Always demand material certifications from your supplier.

The Importance of Diligent Vetting

The ease of finding a supplier online can be deceptive. It is critical to perform due diligence beyond the initial quote.

Look for evidence of experience with fluoropolymers, ask for case studies or references, and confirm their quality control processes before committing to a production run.

How to Source Your Teflon Parts Effectively

Your sourcing strategy should align directly with your project's most critical priority.

- If your primary focus is speed for rapid prototyping: Use a digital platform that can route your job to a vetted domestic partner or engage a local specialist shop you trust.

- If your primary focus is cost-efficiency for volume production: Global sourcing offers the most significant competitive advantage, but requires a robust vetting process to ensure quality and material authenticity.

- If your primary focus is mission-critical quality and traceability: Partner directly with an ISO 9001-certified manufacturer that specializes in Teflon and provides comprehensive material certifications, regardless of their location.

Ultimately, globalization empowers you with more choices, but it also demands a more strategic approach to supplier selection.

Summary Table:

| Impact of Globalization | Key Benefit |

|---|---|

| Access to Expertise | Connect with specialized shops for high-precision PTFE machining. |

| Higher Quality Standards | Global competition drives innovation and adoption of ISO 9001. |

| Competitive Pricing | Instant quotes from a global network lower costs. |

| Logistical Efficiency | Reliable international shipping delivers parts in days. |

Need precision-machined PTFE components?

Globalization offers incredible opportunities, but partnering with the right specialist is key to mitigating risks like material authenticity and communication delays. KINTEK is your trusted, high-quality manufacturing partner.

We specialize in machining PTFE (Teflon) and other fluoropolymers for the semiconductor, medical, laboratory, and industrial sectors. Our focus on precision production and rigorous quality control ensures you receive components that meet the highest standards, backed by full material certifications.

Whether you need rapid prototypes or high-volume production, we offer custom fabrication to your exact specifications.

Let's discuss your project. Contact KINTEK today for a quote and experience the difference expertise makes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments