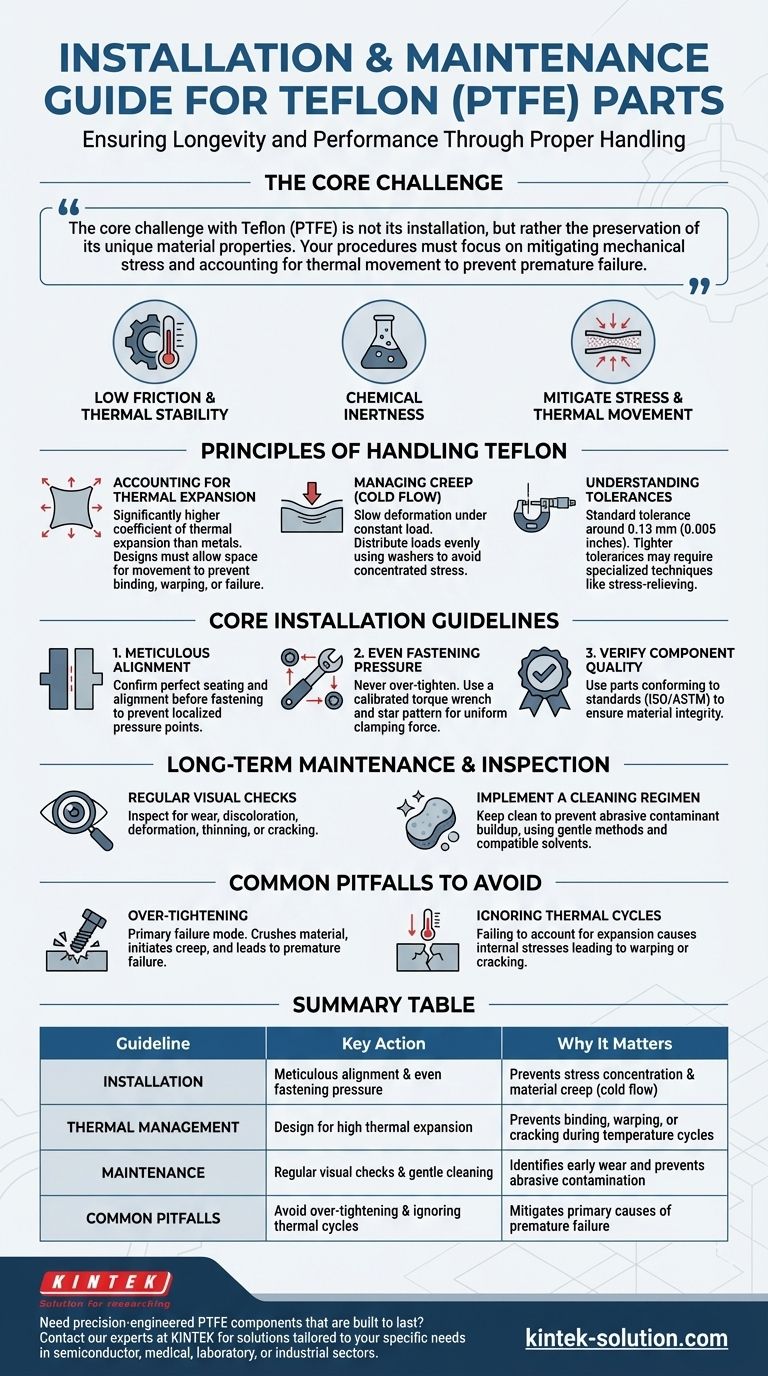

To ensure the longevity and performance of Teflon parts, proper installation requires meticulous alignment and evenly distributed fastening pressure, while maintenance demands regular checks for wear, tear, and cleanliness. These steps are critical for accommodating the material's unique properties, such as its tendency to creep under load and expand with temperature changes.

The core challenge with Teflon (PTFE) is not its installation, but rather the preservation of its unique material properties. Your procedures must focus on mitigating mechanical stress and accounting for thermal movement to prevent premature failure.

The Principles of Handling Teflon

Before touching a single tool, understanding why Teflon requires special handling is essential. Its value comes from a unique combination of properties, including low friction, chemical inertness, and high-temperature stability. Improper handling can compromise these very features.

Accounting for Thermal Expansion

Teflon has a significantly higher coefficient of thermal expansion than metals. This means it expands and contracts much more with temperature changes.

Designs must incorporate space for this movement. Without it, a part that fits perfectly at room temperature may bind, warp, or fail when the system reaches its operating temperature.

Managing Creep (Cold Flow)

Teflon is a soft material that can slowly deform over time when subjected to a constant load, a phenomenon known as creep or cold flow.

To prevent this, loads must be distributed evenly across the part's surface. Using washers or broad fastening points is critical to avoid concentrated stress that can cause the material to deform and fail.

Understanding Tolerances

Due to its flexibility, standard machining tolerances for Teflon are typically around 0.13 mm (0.005 inches).

Achieving tighter tolerances is possible but often requires specialized techniques, such as stress-relieving the material before final machining, to ensure dimensional stability.

Core Installation Guidelines

A successful installation is a direct result of applying the principles above. Precision and control are more important than force.

Ensure Meticulous Alignment

Misalignment is a primary cause of uneven stress and premature wear. Before fastening, confirm that the Teflon component is perfectly seated and aligned with mating parts.

This simple step prevents localized pressure points that accelerate material creep and can lead to leaks or mechanical failure.

Apply Even Fastening Pressure

Never over-tighten fasteners on Teflon components. The goal is a secure fit, not maximum torque.

Use a calibrated torque wrench and follow a star or cross pattern when tightening bolts to distribute the clamping force evenly. This is the single most effective way to prevent cold flow around fastening points.

Verify Component Quality

Always use parts that conform to recognized standards, such as ISO or ASTM requirements. Reputable suppliers perform rigorous testing to ensure operational reliability and material integrity.

This initial quality check ensures you are not installing a component with inherent flaws that will undermine even the best installation practices.

Long-Term Maintenance and Inspection

Once installed, a consistent maintenance schedule preserves the component's function and extends its service life.

Schedule Regular Visual Checks

Implement a routine for visually inspecting Teflon parts for signs of wear, discoloration, or deformation.

Look for thinning in high-load areas, surface cracking, or any indication that the part is changing shape. These are early warnings of impending failure.

Implement a Cleaning Regimen

Although Teflon is highly resistant to chemicals, keeping components clean prevents the buildup of abrasive contaminants that can accelerate physical wear.

Use gentle cleaning methods and compatible solvents to avoid damaging the surface of the material.

Common Pitfalls to Avoid

Understanding what can go wrong is just as important as knowing the correct procedure. Certain common mistakes are responsible for the vast majority of Teflon component failures.

Over-tightening is a Primary Failure Mode

The most common mistake is treating Teflon like metal and over-tightening fasteners. This crushes the material, initiates creep, and guarantees a premature failure of the seal or component.

Ignoring Thermal Cycles

A part installed in a cool environment may fail quickly if the system undergoes significant temperature swings. Failure to account for thermal expansion will cause internal stresses that lead to warping or cracking.

Making the Right Choice for Your Goal

Your specific application will determine which of these guidelines requires the most attention.

- If your primary focus is mechanical stability: Prioritize even load distribution and avoid over-torquing fasteners to prevent material creep.

- If your primary focus is high-temperature performance: Ensure the design allows adequate space for thermal expansion and contraction.

- If your primary focus is long-term reliability: Implement a strict schedule for visually inspecting parts for wear, tear, and signs of deformation.

By treating Teflon not as a simple plastic but as a specialized engineering material, you ensure its performance and longevity in any application.

Summary Table:

| Guideline | Key Action | Why It Matters |

|---|---|---|

| Installation | Meticulous alignment & even fastening pressure | Prevents stress concentration & material creep (cold flow) |

| Thermal Management | Design for high thermal expansion | Prevents binding, warping, or cracking during temperature cycles |

| Maintenance | Regular visual checks & gentle cleaning | Identifies early wear and prevents abrasive contamination |

| Common Pitfalls | Avoid over-tightening & ignoring thermal cycles | Mitigates primary causes of premature failure |

Need precision-engineered PTFE components that are built to last?

At KINTEK, we don't just manufacture PTFE seals, liners, and labware—we understand the critical engineering principles that ensure their success in your application. Our expertise in custom fabrication, from prototypes to high-volume orders, guarantees components that are designed to properly manage creep, thermal expansion, and mechanical stress from the start.

Let us provide a solution tailored for your specific needs in the semiconductor, medical, laboratory, or industrial sectors.

Contact our experts today to discuss your requirements and ensure optimal performance and longevity for your critical systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance