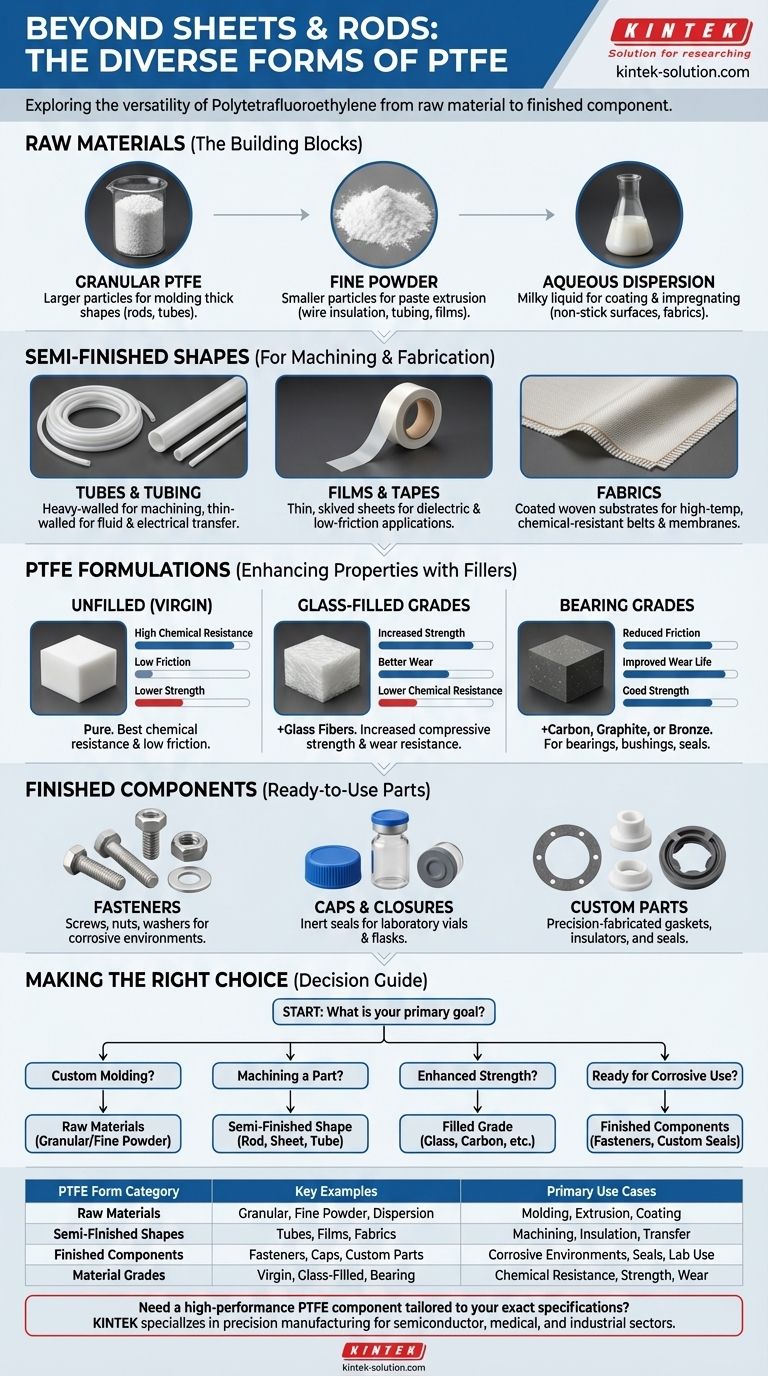

Beyond the standard sheets and rods, Polytetrafluoroethylene (PTFE) is available in a vast array of forms, including flexible tapes, fabrics, and tubing. It also exists in foundational states such as granular powders and water-based dispersions, and as finished components like screws, nuts, and specialized caps.

The true versatility of PTFE lies not just in its variety of semi-finished shapes, but in its availability at every stage of the manufacturing process—from raw powders and dispersions to specialized material grades and precision-fabricated components.

From Raw Material to Solid Form

To understand the shapes PTFE can take, it's essential to start with its unprocessed forms. These raw materials are the building blocks for all other PTFE products.

Granular PTFE

Granular PTFE resin is produced directly from the polymerization process. It's the ideal choice for creating robust molded shapes like rods, tubes, and thick sheets through compression molding.

Fine Powder

Fine powder, also known as coagulation-dispersed powder, consists of much smaller particles. This form is used for paste extrusion to create thinner products like wire insulation, tubing, and films.

Aqueous Dispersion

This is a milky liquid where fine PTFE particles are suspended in water. It's primarily used for coating and impregnating other materials, such as creating non-stick surfaces on cookware or weather-resistant coatings on fabrics like fiberglass.

Common Semi-Finished Shapes

These are the most common forms used for machining and fabrication. They are created from the raw materials mentioned above through processes like molding, extrusion, or skiving.

Tubes and Tubing

PTFE is available as molded or extruded tubes. These range from heavy-walled tubes used for machining custom parts to thin-walled tubing (including convoluted and AWG sizes) for fluid transfer and electrical insulation.

Films and Tapes

Extremely thin PTFE sheets are "skived" from a large molded cylinder, creating films and tapes. These are valued for their dielectric strength in electronics and low-friction properties in industrial applications.

Fabrics

PTFE can be used to coat woven substrates like fiberglass, resulting in a durable, high-temperature, and chemically resistant fabric. This material is common in architectural membranes, conveyor belts, and expansion joints.

Understanding PTFE Formulations (Grades)

The properties of any PTFE shape can be dramatically altered by adding fillers. The choice of grade is as important as the choice of form.

Unfilled (Virgin) Grade

This is pure, unfilled PTFE. It offers the highest chemical resistance and lowest coefficient of friction but has lower mechanical strength and wear resistance compared to filled grades.

Glass-Filled Grades

Adding glass fibers significantly increases compressive strength and wear resistance. This is a common choice for applications requiring more rigidity than virgin PTFE can provide.

Bearing Grades

These grades are filled with materials like carbon, graphite, or bronze. The fillers enhance mechanical properties, reduce friction, and improve wear life, making them ideal for bearings, bushings, and seals.

Fabricated and Finished Components

Beyond raw materials and stock shapes, PTFE is used to create a wide range of ready-to-use parts.

Fasteners

Because of its extreme chemical resistance, PTFE is used to make fasteners like screws, hex nuts, and washers. These are critical for assemblies used in corrosive chemical environments.

Caps and Closures

PTFE is also used to produce or line various caps and closures for laboratory vials, flasks, and tubes. These provide an inert, non-reactive seal for sensitive contents.

Custom-Fabricated Parts

Using services like laser cutting, stamping, and die-cutting, semi-finished PTFE shapes can be fabricated into highly precise custom components, such as gaskets, insulators, and seals tailored to specific requirements.

Making the Right Choice for Your Application

Selecting the correct form and formulation of PTFE is critical to the success of your project. Your end goal dictates your starting point.

- If your primary focus is creating custom molded parts: Start with raw materials like granular or fine powder PTFE.

- If your primary focus is machining a specific component: Begin with a semi-finished shape like a rod, sheet, or tube in the appropriate grade.

- If your primary focus is enhanced strength and wear resistance: Choose a filled grade, such as glass-filled or a bearing-grade formulation.

- If your primary focus is a ready-to-use part for a corrosive environment: Look for finished components like PTFE fasteners or custom-fabricated seals.

Ultimately, understanding the full spectrum of PTFE options empowers you to select the most efficient and effective material for your specific engineering challenge.

Summary Table:

| PTFE Form Category | Key Examples | Primary Use Cases |

|---|---|---|

| Raw Materials | Granular Powder, Fine Powder, Aqueous Dispersion | Molding, Extrusion, Coating |

| Semi-Finished Shapes | Tubes/Tubing, Films/Tapes, Coated Fabrics | Machining, Electrical Insulation, Fluid Transfer |

| Finished Components | Fasteners (Screws, Nuts), Caps, Custom Parts | Corrosive Environments, Seals, Laboratory Use |

| Material Grades | Virgin (Unfilled), Glass-Filled, Bearing Grades | Chemical Resistance, Strength, Wear Resistance |

Need a high-performance PTFE component tailored to your exact specifications?

KINTEK specializes in the precision manufacturing of PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We leverage the full spectrum of PTFE forms and grades to deliver superior chemical resistance, low friction, and durability.

Whether you require a prototype or a high-volume order, our custom fabrication services ensure you get the right part for your application.

Contact KINTEK today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the role of persulphate in PTFE production? Unlocking the Key to Polymerization

- What are the properties of pure PTFE material? Unlock Superior Chemical & Thermal Performance

- Why is PTFE particularly suitable for electrical insulation? Unmatched Dielectric Strength & Resilience

- Does Teflon release harmful gases when heated? Understanding Safe Cooking Temperatures

- What is PTFE and what is its commercial name? A Guide to Teflon and ePTFE

- What applications are PTFE laminated membrane filters suitable for? Master Filtration for Harsh Chemicals

- What makes PTFE plastic uniquely versatile across industries? The 4 Key Properties Explained