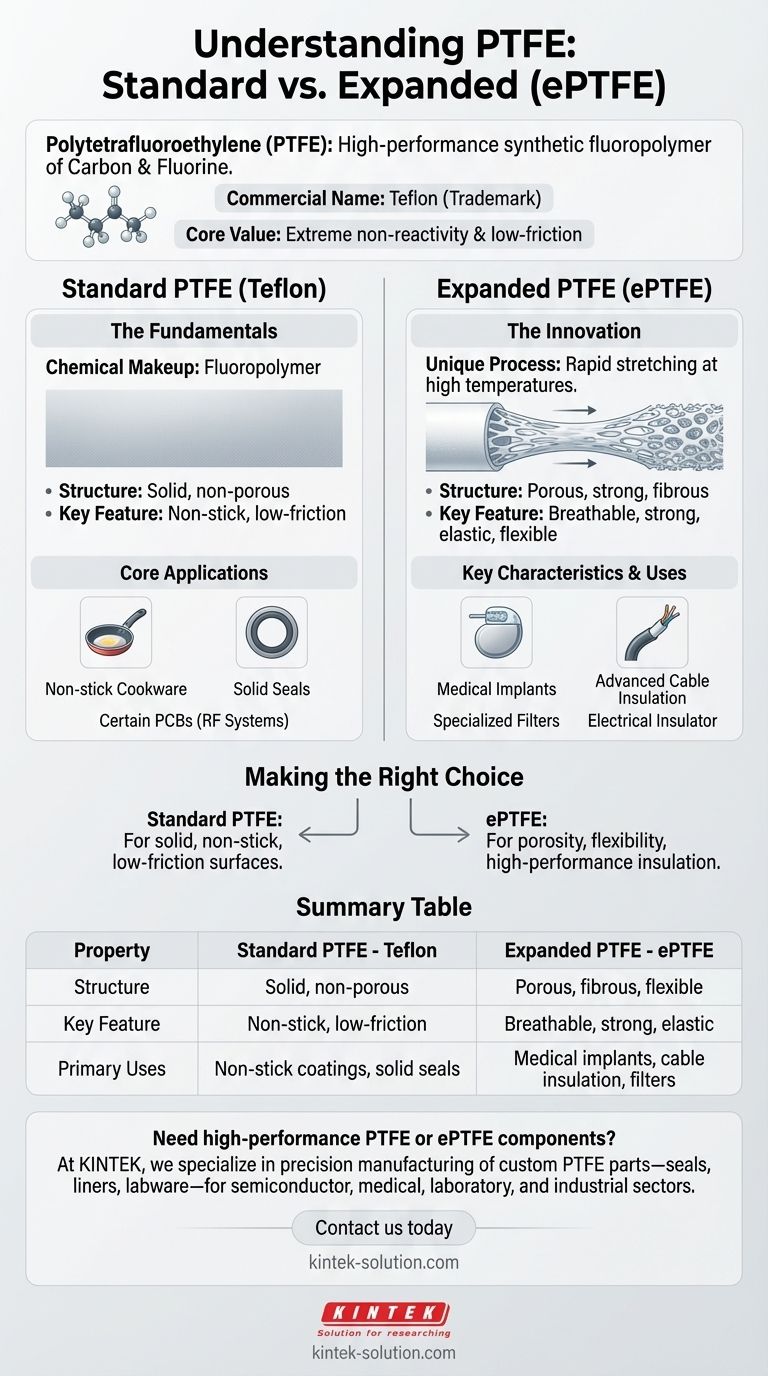

In technical terms, PTFE stands for polytetrafluoroethylene, a high-performance synthetic polymer composed of carbon and fluorine. While it has several commercial names, it is overwhelmingly known by its most famous trademark, Teflon.

At its core, PTFE is valued for its extreme non-reactivity and low-friction surface. Understanding its two primary forms—solid PTFE and expanded PTFE (ePTFE)—is the key to unlocking its use in everything from cookware to advanced electronics and medical devices.

The Fundamentals of Standard PTFE

Chemical Makeup and Identity

Polytetrafluoroethylene (PTFE) is a fluoropolymer, a type of plastic that contains fluorine atoms. This specific chemical structure is what grants the material its remarkable properties.

The name Teflon is a registered trademark, not a generic term for the material itself. It has become synonymous with PTFE due to its widespread use in consumer products.

Core Applications

PTFE's most famous application is in non-stick coatings for frying pans and other cookware.

However, it is also a material of choice in technical fields, particularly for manufacturing Printed Circuit Boards (PCBs) used in high-frequency radio frequency (RF) systems due to its excellent insulating properties.

The Innovation of Expanded PTFE (ePTFE)

A Unique Manufacturing Process

Expanded PTFE, or ePTFE, begins as 100% pure PTFE material. It is produced through a specialized process of rapid stretching at high temperatures.

This expansion process transforms the solid material into a microporous structure. It creates a network of interconnected microfibers and pores while retaining all the inherent chemical properties of the original PTFE.

Key Characteristics of ePTFE

The resulting material is highly porous, strong, and fibrous. It is often described as a white, elastic, and flexible polymer.

These unique structural properties make ePTFE an excellent electrical insulator, often used for wrapping sensitive cables and as an insulating medium in complex electrical systems. It is also widely used as a medical-grade polymer for implants and other devices.

Understanding the Trade-offs: PTFE vs. ePTFE

When to Use Standard PTFE

Standard, solid PTFE is the default choice for applications where a non-porous, low-friction surface is the primary requirement. This includes coatings, solid seals, and certain electronic components where porosity is not needed.

When to Use Expanded PTFE (ePTFE)

You must use ePTFE when the application demands porosity, breathability, or enhanced flexibility. Its fibrous, strong structure makes it indispensable for medical implants, advanced cable insulation, and specialized filters.

The choice is not about which is "better," but which structure is appropriate for the specific engineering problem you are trying to solve.

Making the Right Choice for Your Goal

Selecting the correct form of this polymer is critical for project success. Base your decision on the required physical structure of the material.

- If your primary focus is a solid, non-stick, or low-friction surface: Your solution is standard PTFE, commonly sourced under the Teflon brand.

- If your primary focus is porosity, flexibility, and high-performance insulation: You require the structurally modified expanded PTFE (ePTFE).

Ultimately, understanding the difference between the base polymer and its expanded variant allows you to leverage its powerful properties correctly.

Summary Table:

| Property | Standard PTFE (Teflon) | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Solid, non-porous | Porous, fibrous, flexible |

| Key Feature | Non-stick, low-friction | Breathable, strong, elastic |

| Primary Uses | Non-stick coatings, solid seals | Medical implants, cable insulation, filters |

Need high-performance PTFE or ePTFE components for your project?

At KINTEK, we specialize in the precision manufacturing of custom PTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get the right material solution for your application.

Contact us today to discuss your specific requirements and let us help you achieve optimal performance with the right PTFE material.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications