Pure PTFE is defined by a unique combination of properties, most notably its extremely low friction, outstanding chemical resistance, and a very wide operating temperature range. It is also an excellent electrical insulator and is considered biocompatible, making it suitable for a vast array of demanding technical applications.

While PTFE is renowned for its exceptional chemical inertness and non-stick surface, its true value is in its reliability across extreme thermal and electrical environments. However, this high performance is balanced by a notable trade-off in mechanical strength and rigidity.

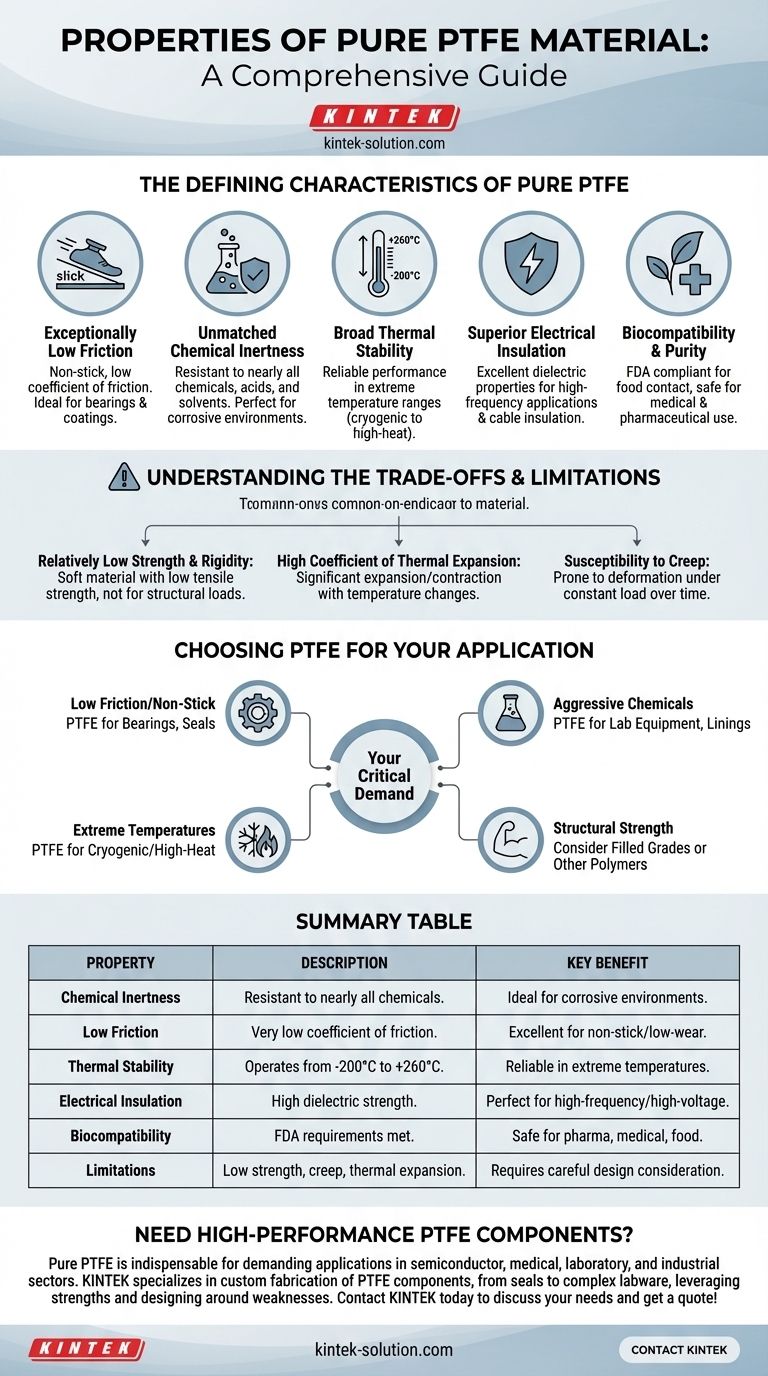

The Defining Characteristics of Pure PTFE

Polytetrafluoroethylene (PTFE), often recognized by the brand name Teflon, is a high-performance fluoropolymer. Its properties stem directly from its stable molecular structure, which consists of a carbon chain fully surrounded by fluorine atoms.

Unmatched Chemical Inertness

PTFE exhibits extraordinary resistance to nearly all chemicals, including strong acids, aggressive alkalis, and organic solvents. This inertness makes it a premier choice for seals, gaskets, and linings in corrosive environments where other materials would quickly degrade.

Exceptionally Low Friction

One of its most famous attributes is its very low coefficient of friction. This gives PTFE its characteristic non-stick, or "slick," surface, making it ideal for applications like low-friction bearings, slide plates, and non-stick coatings where smooth movement and easy release are critical.

Broad Thermal Stability

Pure PTFE performs reliably across an incredibly wide temperature range, typically from -200°C up to +260°C (-328°F to +500°F). It maintains its properties in cryogenic conditions and at high temperatures that would melt or embrittle most other plastics.

Superior Electrical Insulation

With a low dielectric constant and high dielectric strength, PTFE is an excellent electrical insulator. This property makes it a key material for high-frequency applications, cable insulation, and components in circuit boards.

Biocompatibility and Purity

Pure PTFE is biocompatible and meets FDA requirements for food contact applications. Its inherent purity and resistance to harboring contaminants make it a standard material in the medical, pharmaceutical, and food processing industries.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. To use PTFE effectively, it is crucial to understand its limitations, which are primarily mechanical.

Relatively Low Strength and Rigidity

Compared to many engineering plastics, pure PTFE is a relatively soft material. It has low tensile strength and stiffness, which means it is not suitable for applications requiring high structural integrity or load-bearing capacity on its own.

High Coefficient of Thermal Expansion

PTFE expands and contracts more significantly with temperature changes than metals or other plastics. This must be accounted for in designs with tight tolerances to prevent parts from seizing or failing under thermal cycling.

Susceptibility to Creep

Due to its relative softness, PTFE is prone to "creep," which is the tendency to slowly deform over time when under a constant load. This is a critical consideration for static seals or any component under sustained pressure.

Choosing PTFE for Your Application

Your final decision should be guided by the most critical demand of your project.

- If your primary focus is low friction or a non-stick surface: PTFE is a world-class choice for bearings, seals, and specialized coatings.

- If your primary focus is handling aggressive chemicals: Its near-total chemical inertness makes it ideal for lab equipment, valve components, and vessel linings.

- If your primary focus is performance in extreme temperatures: PTFE's stability in both cryogenic and high-heat environments is a key advantage.

- If your primary focus is structural strength under load: You should consider filled grades of PTFE (e.g., glass or carbon-filled) or a different engineering polymer entirely.

By understanding both its unique strengths and inherent mechanical limitations, you can leverage pure PTFE to solve some of engineering's most demanding challenges.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all chemicals, acids, and solvents. | Ideal for corrosive environments. |

| Low Friction | Very low coefficient of friction. | Excellent for non-stick and low-wear applications. |

| Thermal Stability | Operates from -200°C to +260°C. | Reliable performance in extreme temperatures. |

| Electrical Insulation | High dielectric strength and low dielectric constant. | Perfect for high-frequency and high-voltage uses. |

| Biocompatibility | Meets FDA requirements for food and medical use. | Safe for pharmaceutical, medical, and food industries. |

| Limitations | Low mechanical strength, prone to creep, high thermal expansion. | Requires careful design consideration for structural loads. |

Need High-Performance PTFE Components?

Pure PTFE's unique properties make it indispensable for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. However, its mechanical limitations mean that successful application requires expert design and precision manufacturing.

KINTEK specializes in the custom fabrication of PTFE components—from seals and liners to complex labware. We help you leverage PTFE's strengths while designing around its weaknesses, ensuring optimal performance and reliability.

Whether you need a prototype or high-volume production, our team is ready to deliver the precision you require.

Contact KINTEB today to discuss your PTFE component needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance