The choice between bronze and PTFE bushings is a critical engineering decision that hinges on four primary factors: load capacity, friction requirements, maintenance access, and the operating environment. Bronze bushings are metal alloy bearings prized for their strength and durability, while PTFE (polytetrafluoroethylene) bushings are polymer bearings renowned for their extremely low friction and self-lubricating properties.

The core decision comes down to a fundamental trade-off: Bronze offers superior strength for high-load applications but requires lubrication. PTFE provides maintenance-free, low-friction performance but is suited for lighter loads.

Deconstructing the Materials

To make an informed choice, you must first understand the inherent nature of each material. They are not interchangeable; they are designed to solve different problems.

What is a Bronze Bushing?

A bronze bushing is a classic, robust bearing made from a copper alloy. It's a traditional solution known for its high strength and wear resistance.

Its performance is defined by its ability to handle significant pressure and impact. However, to prevent metal-on-metal seizure and premature wear, it almost always relies on a film of grease or oil.

What is a PTFE Bushing?

A PTFE bushing is a modern polymer bearing. PTFE is the same material better known by the brand name Teflon.

Its defining characteristic is an exceptionally low coefficient of friction. This material is inherently "slippery," allowing it to operate smoothly without any external lubrication, which is why it's often called self-lubricating.

Key Decision Factors: A Head-to-Head Comparison

Your specific application will demand certain performance characteristics. By comparing the materials across these key factors, the correct choice often becomes clear.

Load Capacity and Durability

Bronze bushings are the clear winner for high-load applications. Their metallic structure provides excellent compressive strength, making them ideal for heavy machinery, construction equipment, and high-impact industrial environments.

PTFE bushings are best suited for light to moderate loads. Under excessive pressure, the polymer can deform or "creep," leading to a loss of tolerance and eventual failure.

Friction and Lubrication

Bronze bushings have higher friction and are dependent on lubrication. A consistent film of grease or oil is critical to create a hydrodynamic layer that separates the shaft from the bushing, reducing wear and heat.

PTFE bushings are the standard for low-friction needs. Their self-lubricating nature eliminates the need for grease or oil, making them perfect for applications where maintenance is difficult, undesirable, or where lubricants could contaminate the product (e.g., food processing).

Operating Environment

Bronze bushings perform well across a wide temperature range but can be vulnerable to corrosion in wet or chemically aggressive environments unless they are specifically treated or made from a corrosion-resistant alloy.

PTFE bushings offer superior chemical resistance. They are virtually inert to most acids, bases, and solvents, making them an excellent choice for chemical processing or marine applications.

Noise and Speed

Bronze bushings can generate noise, especially if lubrication is inadequate. The metal-on-metal contact, even when lubricated, is inherently noisier than polymer contact.

PTFE bushings provide virtually silent operation. The smooth, low-friction sliding action makes them ideal for applications where noise is a primary concern, such as in office equipment or medical devices.

Understanding the Trade-offs

Choosing a bushing isn't just about picking the "best" material; it's about accepting the right set of compromises for your design.

The Maintenance vs. Strength Dilemma

The most common trade-off is strength versus maintenance. If you select bronze for its superior load capacity, you are also committing to a maintenance schedule. Neglecting lubrication is the fastest way to cause a bronze bushing to fail.

Conversely, choosing PTFE gives you a "fit-and-forget" component that requires no maintenance. However, you must design your system to operate within the bushing's lower load and durability limits.

Total Cost of Ownership

While a standard bronze bushing might have a lower initial purchase price, the total cost of ownership can be higher. You must factor in the cost of lubricants, the labor required for regular maintenance, and the potential downtime if maintenance is missed.

A PTFE bushing may have a higher upfront cost, but its maintenance-free operation can result in a lower total cost over the life of the product.

Making the Right Choice for Your Application

Use your primary design constraint as your guide to select the appropriate material.

- If your primary focus is high load and maximum durability: Bronze is the clear choice, provided you can ensure consistent lubrication.

- If your primary focus is low friction and zero maintenance: PTFE is the superior option, especially in clean or corrosive environments.

- If your primary focus is quiet operation: PTFE's self-lubricating properties make it virtually silent and the ideal selection.

- If your primary focus is cost-sensitivity in a high-load scenario: A standard, greaseable bronze bushing is often the most economical solution upfront.

By aligning your application's specific demands with the inherent properties of each material, you can select a bushing that delivers reliable, long-term performance.

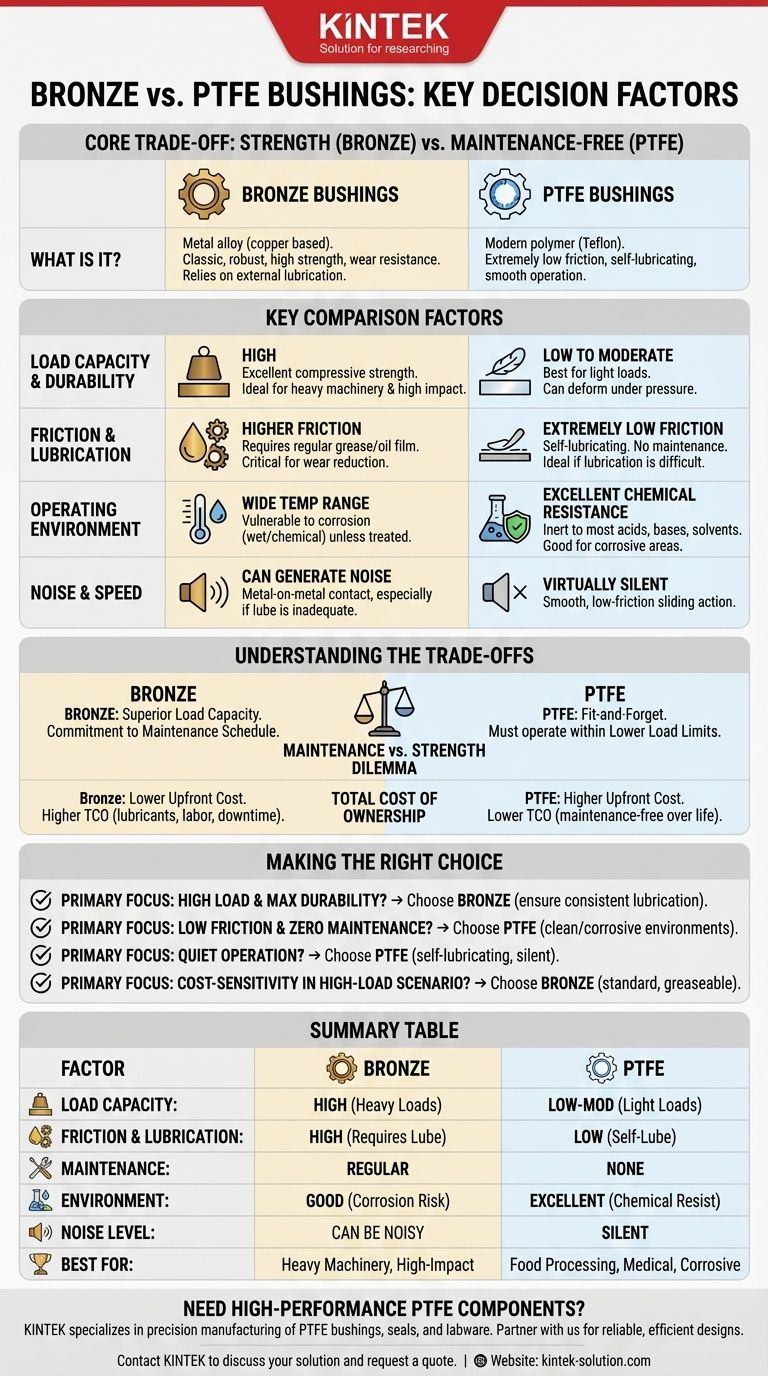

Summary Table:

| Factor | Bronze Bushing | PTFE Bushing |

|---|---|---|

| Load Capacity | High (Ideal for heavy loads) | Low to Moderate (Light loads only) |

| Friction & Lubrication | High friction; Requires lubrication | Extremely low friction; Self-lubricating |

| Maintenance | Regular lubrication needed | Maintenance-free |

| Operating Environment | Good temperature range; Vulnerable to corrosion | Excellent chemical resistance |

| Noise Level | Can be noisy | Virtually silent |

| Best For | Heavy machinery, high-impact applications | Food processing, medical devices, corrosive environments |

Need High-Performance PTFE Components for Your Application?

KINTEK specializes in the precision manufacturing of PTFE components, including custom bushings, seals, liners, and labware. Whether your project is in the semiconductor, medical, laboratory, or industrial sector, we deliver the superior chemical resistance and maintenance-free performance of PTFE with exacting standards.

We partner with you from prototype to high-volume production to ensure your design operates reliably and efficiently.

Contact KINTEB today to discuss your custom PTFE solution and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE sheets used in the medical industry? For Biocompatibility, Inertness & Low Friction

- Why are PTFE gaskets preferred in aerospace applications? Ensuring Reliability in Extreme Conditions

- What maintenance advantages do PTFE compensators offer? Maximize Uptime with Self-Cleaning Design

- What are the disadvantages of using PTFE O-Rings? When Rigidity and Lack of Elasticity Cause Leaks

- What environmental factors should be considered when choosing PTFE sheets? Ensure Long-Term Performance

- How is glass-filled PTFE used in construction? Enhance Structural Integrity & Durability

- How are Teflon rods applied in the automotive and aerospace industries? Solve Friction, Heat, and Chemical Challenges

- What troubleshooting tips are recommended for machining Teflon? Master PTFE with Sharp Tools & Heat Control