When troubleshooting Teflon machining, the most immediate and effective steps are to verify your cutting speed is appropriate, ensure your tools are exceptionally sharp, and confirm the workpiece is securely clamped to prevent vibration and movement. These three factors are the most common culprits for poor surface finish and dimensional inaccuracy.

The core challenge of machining Teflon (PTFE) is not its hardness, but its unique combination of softness, slipperiness, and high thermal expansion. Success requires abandoning conventional metalworking approaches and instead focusing on techniques that manage these properties with finesse rather than force.

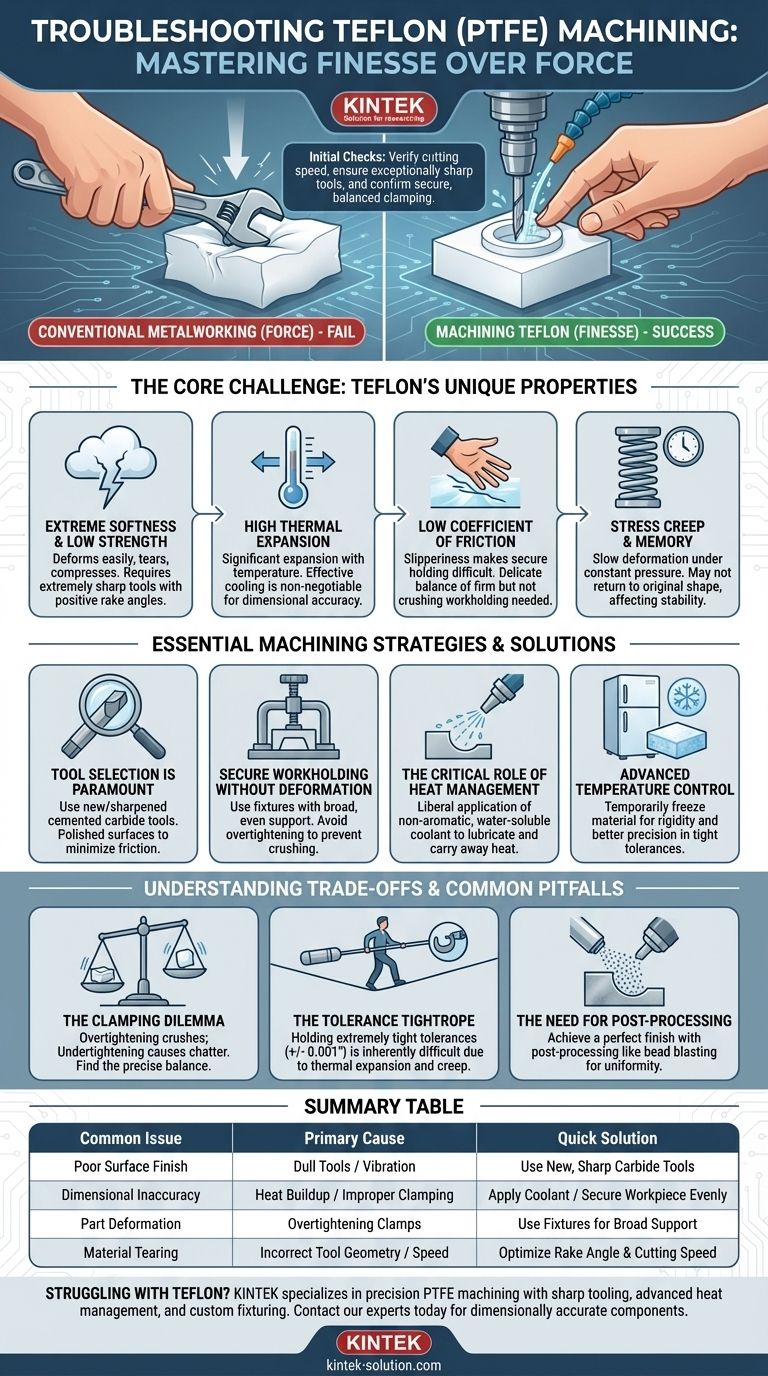

The Core Challenge: Understanding Teflon's (PTFE) Unique Properties

To move from troubleshooting to true mastery, you must understand the material's inherent characteristics. Each property directly influences the required machining strategy.

Extreme Softness and Low Strength

Teflon deforms easily under pressure. Unlike metals, it will compress or tear rather than shear cleanly if the wrong tools or forces are applied.

This necessitates the use of extremely sharp tools with positive rake angles and significant relief to slice through the material cleanly without compressing it.

High Thermal Expansion

The material has a very high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Even minor heat generated from cutting friction can ruin dimensional accuracy.

This makes effective cooling and heat management a non-negotiable part of the process.

Low Coefficient of Friction

While beneficial in its final application, Teflon's slipperiness makes it notoriously difficult to hold securely. It can easily slip in a chuck or vise during machining.

Workholding must be firm enough to prevent any movement or vibration, but not so tight that it deforms the soft material. This is a delicate balance.

Stress Creep and Memory

Teflon is prone to "stress creep," meaning it will slowly deform over time when held under constant pressure. When the clamping pressure is released, it may not return to its original shape, affecting the final part's stability.

Essential Machining Strategies and Solutions

Based on these properties, a specific set of strategies has proven effective for achieving high-quality results.

Tool Selection is Paramount

Your cutting tools are the single most important factor. Always use new or freshly sharpened tools.

Choose cemented carbide tools with highly polished surfaces to minimize friction and prevent material from sticking to the tool edge. Tool geometry should be designed to enhance chip clearance and prevent clogging.

Secure Workholding Without Deformation

Properly supporting the material is critical. Use fixtures that provide broad, even support to the workpiece.

Avoid overtightening clamps. The goal is to immobilize the part to prevent chatter and vibration without crushing or distorting its shape.

The Critical Role of Heat Management

Heat is the enemy of precision when machining Teflon. Consistent and liberal application of coolant is essential.

Use a non-aromatic, water-soluble coolant to lubricate the cut, reduce friction, and carry away heat, ensuring dimensional stability.

Advanced Temperature Control

For parts requiring the tightest tolerances, a more advanced technique is to temporarily freeze the material before and during machining.

Freezing makes the Teflon more rigid and less prone to deformation, allowing for more precise cuts. This also helps control the effects of thermal expansion.

Understanding the Trade-offs and Common Pitfalls

Machining Teflon involves balancing competing requirements, and awareness of these trade-offs is key to avoiding common failures.

The Clamping Dilemma

The most common pitfall is improper workholding. Overtightening will crush the part and induce stress, while under-tightening will cause chatter, poor surface finish, and inaccurate cuts. Finding the precise balance is a matter of experience.

The Tolerance Tightrope

Due to its thermal expansion and tendency to creep, holding extremely tight tolerances (+/- 0.001") is inherently difficult. This requires impeccable process control, including stable ambient temperatures and consistent cooling.

The Need for Post-Processing

Achieving a perfect finish directly off the machine can be challenging. It is common to include a post-processing step, such as bead blasting, to achieve a final uniform and smooth surface.

Making the Right Choice for Your Goal

Select your primary focus to determine your most critical adjustments.

- If your primary focus is high precision and tight tolerances: Prioritize aggressive heat management with coolants and consider freezing the workpiece.

- If your primary focus is a superior surface finish: Concentrate on using exceptionally sharp, polished carbide tools and ensuring zero workpiece vibration.

- If your primary focus is simply avoiding common failures: Master the fundamentals of secure (but not crushing) workholding and using the correct cutting speeds.

Ultimately, mastering Teflon machining is about respecting the material's unique properties, not fighting against them.

Summary Table:

| Common Issue | Primary Cause | Quick Solution |

|---|---|---|

| Poor Surface Finish | Dull Tools / Vibration | Use New, Sharp Carbide Tools |

| Dimensional Inaccuracy | Heat Buildup / Improper Clamping | Apply Coolant / Secure Workpiece Evenly |

| Part Deformation | Overtightening Clamps | Use Fixtures for Broad Support |

| Material Tearing | Incorrect Tool Geometry / Speed | Optimize Rake Angle & Cutting Speed |

Struggling with Teflon's unique properties? KINTEK specializes in precision PTFE machining for the semiconductor, medical, and laboratory industries. We leverage sharp tooling, advanced heat management, and custom fixturing to overcome softness, thermal expansion, and stress creep—delivering dimensionally accurate seals, liners, and labware from prototypes to high-volume orders.

Contact our experts today to discuss your custom PTFE component needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech