When selecting a PTFE sheet, the primary environmental factors to evaluate are its chemical compatibility, operating temperature range, and exposure to physical stressors like pressure and UV radiation. Polytetrafluoroethylene (PTFE) is known for its exceptional resilience, but understanding the specific limits of the material is critical for ensuring reliability and safety in any demanding application. A thorough assessment prevents premature failure and guarantees the component's longevity.

While standard PTFE offers remarkable resistance across a wide spectrum of environments, the critical task is to identify if your application involves extreme conditions. Aggressive chemicals, cryogenic temperatures, or high mechanical stress may necessitate a specific grade or compound of PTFE for guaranteed performance.

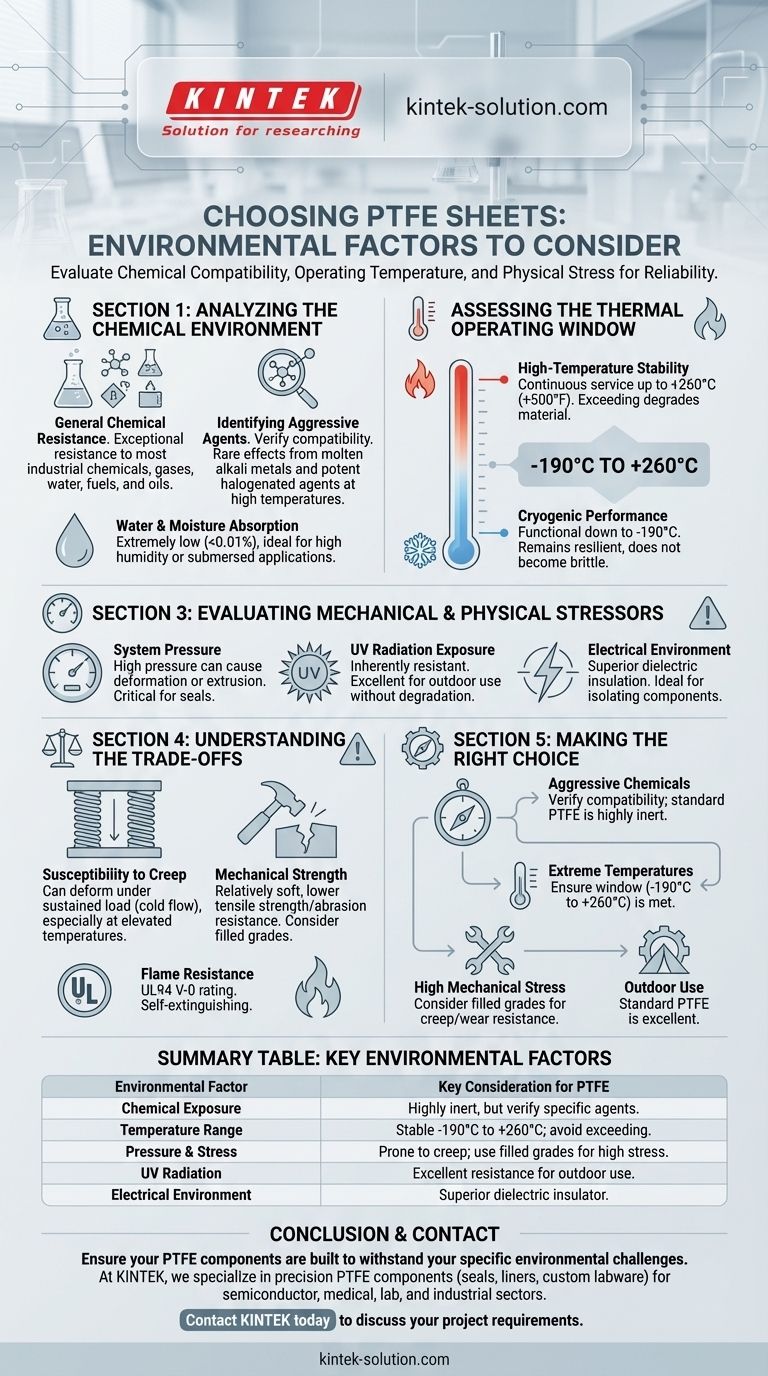

Analyzing the Chemical Environment

The chemical inertness of PTFE is one of its most valuable properties. However, a detailed review of the substances it will contact is a mandatory step in the selection process.

General Chemical Resistance

PTFE exhibits exceptional resistance to a vast array of substances. This includes most industrial chemicals, gases, water, fuels, and oils, making it a default choice for many corrosive environments.

Identifying Aggressive Agents

While PTFE is largely inert, you must verify its compatibility with your specific process chemicals. In rare cases, certain substances like molten alkali metals and potent halogenated agents at high temperatures can affect PTFE.

Water and Moisture Absorption

The material has extremely low water absorption (less than 0.01%). This property makes PTFE sheets ideal for applications in high-humidity environments or even for components that are fully submersed.

Assessing the Thermal Operating Window

PTFE is valued for its ability to perform consistently across an exceptionally broad range of temperatures, from cryogenic lows to significant heat.

High-Temperature Stability

The continuous service temperature for most PTFE sheets is +260°C (+500°F). Pushing beyond this limit can lead to the material degrading and releasing fumes, compromising its structural integrity and creating a safety hazard.

Cryogenic Performance

On the other end of the spectrum, PTFE remains functional and resilient down to -190°C. Unlike many plastics that become brittle and fail at low temperatures, PTFE maintains its key properties.

Evaluating Mechanical and Physical Stressors

Beyond chemical and thermal factors, the physical forces acting upon the PTFE sheet are just as important for ensuring long-term stability.

System Pressure

High pressure is a significant environmental stressor. In applications like gaskets and seals, excessive pressure can cause the material to deform or extrude from its intended position, leading to seal failure.

UV Radiation Exposure

PTFE is inherently resistant to UV radiation and is considered non-aging. This makes it an excellent choice for outdoor applications or any environment with prolonged exposure to sunlight without risk of degradation.

Electrical Environment

Because PTFE has very good dielectric insulation properties, it is frequently used to isolate electrical components. The surrounding electrical field and the need for insulation should be considered a critical environmental factor in these use cases.

Understanding the Trade-offs

No material is without limitations. Objectively assessing PTFE's trade-offs is crucial for successful implementation and avoiding common pitfalls.

Susceptibility to Creep

A primary limitation of standard PTFE is its tendency to "creep" or experience cold flow. Under a sustained mechanical load, especially at elevated temperatures, the material can slowly deform over time.

Mechanical Strength

Compared to other engineering plastics, virgin PTFE is a relatively soft material with lower tensile strength and abrasion resistance. This is a direct trade-off for its superior chemical inertness and low-friction surface. For high-wear applications, filled grades of PTFE are often required.

Flame Resistance

PTFE is naturally flame resistant, carrying a UL94 V-0 rating. This means it will self-extinguish after the flame source is removed, making it a safe choice for applications where fire risk is a concern.

Making the Right Choice for Your Application

Base your selection on the most extreme environmental condition your component will face. This ensures a margin of safety and predictable performance.

- If your primary focus is aggressive chemical exposure: Verify compatibility with your specific agents, but know that standard PTFE is one of the most inert materials available.

- If your primary focus is an extreme temperature range: Ensure your operating window falls comfortably within PTFE's –190°C to +260°C (–310°F to +500°F) range for reliable performance.

- If your primary focus is high mechanical stress or pressure: Consider filled grades of PTFE, which enhance resistance to creep and wear, or ensure your design accounts for standard PTFE's softness.

- If your primary focus is outdoor or UV-heavy use: Standard PTFE is an excellent choice due to its inherent, long-term resistance to UV degradation.

A thorough analysis of your operating environment is the most effective way to leverage PTFE's powerful properties and guarantee long-term success.

Summary Table:

| Environmental Factor | Key Consideration for PTFE |

|---|---|

| Chemical Exposure | Highly inert, but verify compatibility with specific aggressive agents. |

| Temperature Range | Stable from -190°C to +260°C; avoid exceeding limits to prevent degradation. |

| Pressure & Stress | Prone to creep under sustained load; consider filled grades for high stress. |

| UV Radiation | Excellent inherent resistance, ideal for outdoor applications. |

| Electrical Environment | Superior dielectric insulator for electrical components. |

Ensure your PTFE components are built to withstand your specific environmental challenges.

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our custom fabrication expertise ensures your parts deliver reliable performance under extreme chemical, thermal, and physical stress.

Contact KINTEK today to discuss your project requirements and receive a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs