When designing CNC machined PTFE parts, the most critical considerations are directly tied to the material's unique properties: its inherent softness, its high rate of thermal expansion, and its tendency to deform under load, a phenomenon known as stress relaxation or creep. Unlike metals, PTFE (Polytetrafluoroethylene) demands a design approach that anticipates and accommodates this behavior to ensure the final part is both manufacturable and functional.

The core challenge of designing with PTFE is not fighting its nature but accommodating it. Success requires shifting your mindset from the rigidity of metals to the dynamic behavior of a soft, thermally sensitive polymer, ensuring your design accounts for how it will move, compress, and settle both during machining and in its final application.

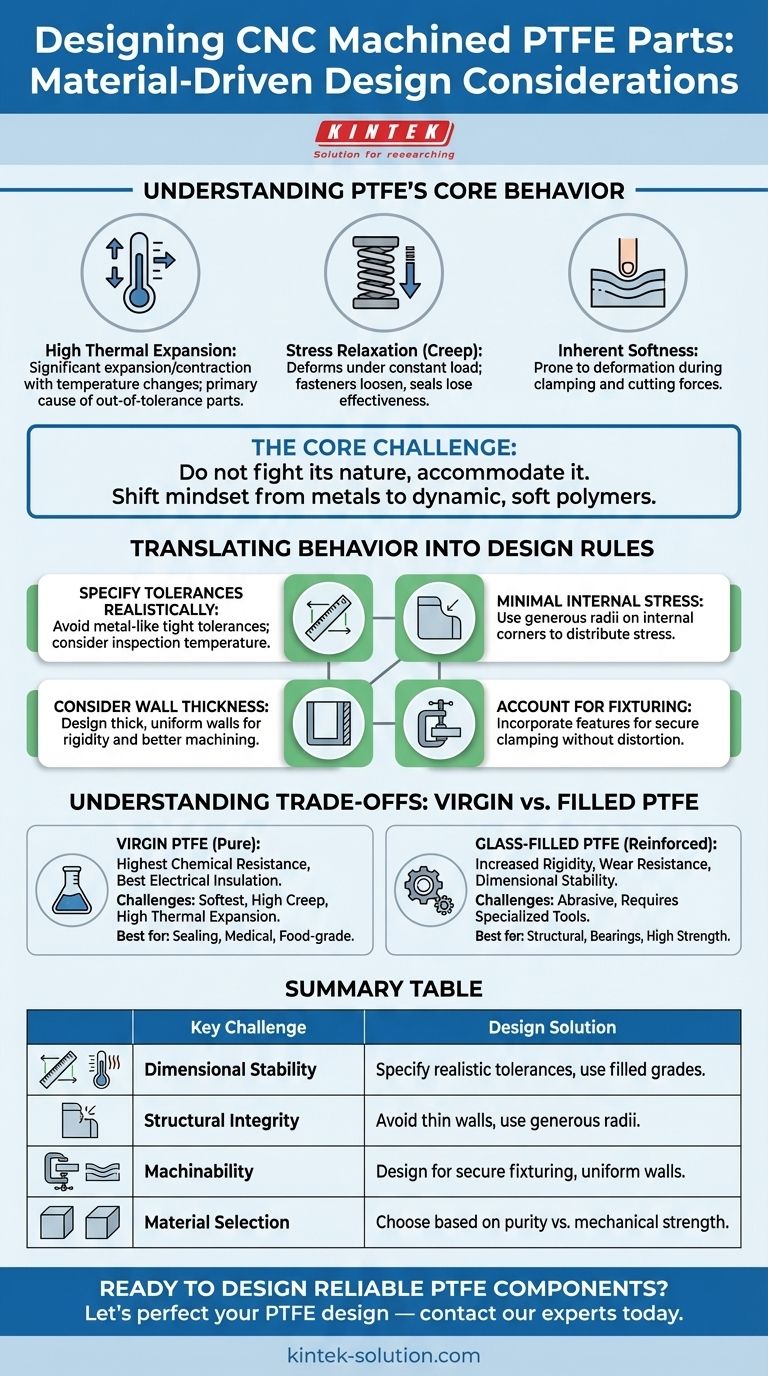

Understanding PTFE's Core Material Behavior

To design effective PTFE components, you must first internalize how the material behaves. Its properties are exceptional for many applications but create specific challenges for machining and dimensional stability.

The Challenge of High Thermal Expansion

PTFE has a coefficient of thermal expansion many times higher than that of most metals. This means it expands and contracts significantly with even minor temperature changes.

A part machined to precise dimensions in a cool shop environment may be out of tolerance once it reaches a warmer operating temperature. This is a primary cause of failed inspections and performance issues.

Stress Relaxation and Creep

When subjected to a constant compressive force, such as from a bolt or in a sealing application, PTFE will slowly deform or "creep" over time.

This stress relaxation means that fasteners can loosen, and seals can lose their effectiveness if the design does not account for this gradual change in shape.

Inherent Softness and Low Rigidity

PTFE is a relatively soft material, which makes it prone to deformation during the machining process itself.

Improper clamping (fixturing) can easily crush or warp a part before a single cut is made. The cutting forces themselves can also cause the material to deflect, leading to inaccuracies.

Translating Material Behavior into Design Rules

Understanding these behaviors allows you to create designs that are practical to manufacture and reliable in service.

Specify Tolerances Realistically

Attempting to hold metal-like tight tolerances on PTFE is often impractical and expensive. The material's thermal instability and softness make it difficult to achieve and maintain such precision.

Where possible, design with looser tolerances. For critical features, consult with your machinist to understand what is realistically achievable and specify the temperature at which inspections should be performed.

Design for Minimal Internal Stress

Sharp internal corners are stress concentrators in any material, but they are especially problematic in PTFE. These features can serve as starting points for tearing or cracking under load.

Always design with generous radii on all internal corners. This distributes stress more evenly and increases the part's durability.

Consider Wall Thickness Carefully

Very thin walls are extremely difficult to machine accurately in PTFE. They are prone to vibrating and deflecting under the pressure of the cutting tool, leading to poor surface finish and dimensional inconsistency.

As a general rule, design walls to be as thick and uniform as the application will allow to provide the necessary rigidity for successful machining.

Account for Fixturing in Your Design

Think about how the raw material will be held during machining. A well-designed part includes features that allow for secure clamping without causing distortion.

For example, incorporating thicker sections or flanges on the periphery of the part can provide a safe and stable area for vices or clamps to grip.

Understanding the Trade-offs: Virgin vs. Filled PTFE

The grade of PTFE you select has a significant impact on its performance and machinability. The two most common choices are virgin and glass-filled.

When to Use Virgin PTFE

Virgin PTFE is pure Polytetrafluoroethylene. It offers the highest chemical resistance, the best electrical insulation properties, and is often required for medical or food-grade applications.

However, it is also the softest and most prone to creep and thermal expansion, making it the most challenging to machine to tight tolerances.

When to Use Glass-Filled PTFE

Glass-filled PTFE contains glass fibers that are compounded into the raw material. This filler dramatically increases the material's rigidity, wear resistance, and dimensional stability.

This grade is ideal for structural components, bearings, or any part that requires higher mechanical strength and less susceptibility to creep. While more stable, the glass filler is abrasive and requires specialized cutting tools.

Making the Right Choice for Your Application

Your final design choices should be guided by the primary function of the component.

- If your primary focus is sealing and chemical purity: Choose virgin PTFE and incorporate features like wide sealing faces and mechanical compression limiters to manage its tendency to creep.

- If your primary focus is mechanical strength and wear resistance: Opt for glass-filled PTFE and design with generous wall thicknesses to leverage its superior rigidity.

- If your primary focus is achieving tight tolerances: Collaborate with your machinist on fixturing strategies and specify a controlled inspection environment to account for thermal expansion.

By designing with PTFE's unique material properties in mind from the start, you can transform its challenges into reliable, high-performance components.

Summary Table:

| Design Consideration | Key Challenge | Design Solution |

|---|---|---|

| Dimensional Stability | High thermal expansion & creep | Specify realistic tolerances; use filled grades (e.g., glass) for stability |

| Structural Integrity | Softness & low rigidity | Avoid thin walls; use generous radii on internal corners |

| Machinability | Deformation during clamping/cutting | Design for secure fixturing; ensure uniform wall thickness |

| Material Selection | Virgin PTFE (soft, pure) vs. Filled (rigid, stable) | Choose based on application: chemical purity vs. mechanical strength |

Ready to design reliable PTFE components?

At KINTEK, we specialize in precision CNC machining of PTFE for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your designs for seals, liners, labware, and other critical parts are optimized for manufacturability and performance, accounting for material behavior from prototype to high-volume production.

Let's perfect your PTFE design — contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications