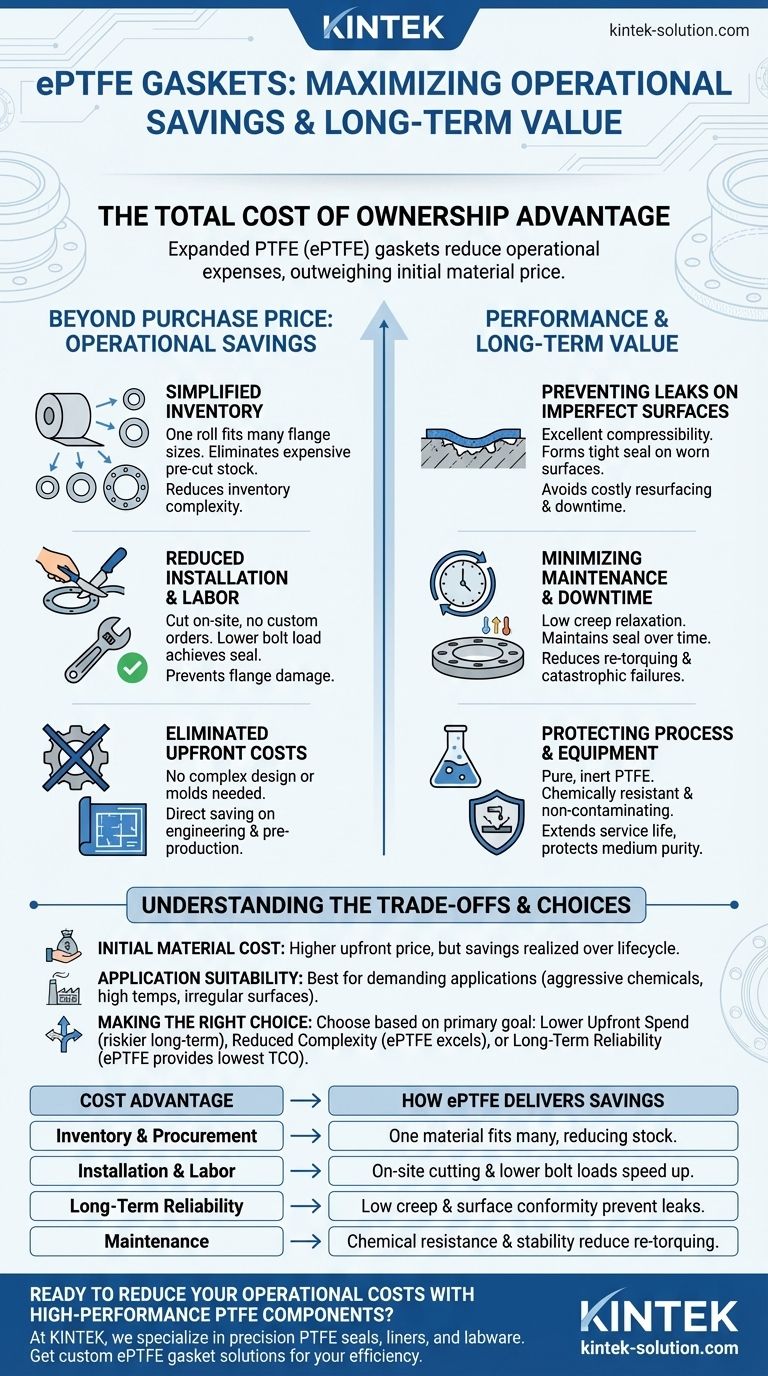

In short, expanded PTFE (ePTFE) gaskets offer significant cost advantages by reducing operational expenses that often outweigh the initial material price. Their primary savings come from simplifying inventory, eliminating the need for pre-formed parts, reducing installation labor, and minimizing costly maintenance and downtime through superior sealing performance.

The true value of expanded PTFE is not found in its sticker price, but in its ability to lower the total cost of ownership. It achieves this by solving common operational problems like complex inventory, difficult installation, and unreliable seals on imperfect surfaces.

Beyond Purchase Price: The Operational Savings

Many of the most significant cost advantages of ePTFE are realized during installation and inventory management, directly impacting your operational budget.

Simplifying Inventory and Procurement

The remarkable flexibility and conformability of ePTFE mean a single roll or sheet of material can be used for a wide variety of flange sizes and shapes.

This versatility dramatically simplifies procurement and reduces the need to stock a large, expensive inventory of pre-cut, application-specific gaskets.

Reducing Installation and Labor Costs

ePTFE gaskets can be easily cut by hand or machine directly on-site. This eliminates the delays and costs associated with ordering custom-made gaskets.

Furthermore, they achieve a reliable seal with lower bolt loads compared to many other materials. This not only makes installation faster but also reduces the risk of damaging sensitive flange surfaces, avoiding future repair costs.

Eliminating Upfront Design Costs

Because ePTFE can be shaped on-site to fit the application perfectly, there is no need for complex upfront design work or the creation of custom molds. This is a direct saving on engineering and pre-production expenses.

How Performance Translates to Long-Term Value

The material properties of ePTFE directly contribute to lower long-term costs by ensuring reliability and preventing expensive failures.

Preventing Leaks on Imperfect Surfaces

ePTFE exhibits excellent compressibility, allowing it to conform perfectly to worn, pitted, or irregular flange surfaces.

This ability to create a tight seal on less-than-ideal surfaces can save the immense cost and downtime associated with having to resurface or replace aging equipment.

Minimizing Maintenance and Downtime

A key characteristic of ePTFE is its extremely low creep relaxation and resistance to cold flow. This means the gasket maintains its shape and sealing pressure over time, even under thermal cycling.

This stability reduces the need for periodic re-torquing of bolts, saving significant maintenance labor. Most importantly, it creates a highly reliable seal that minimizes the risk of leaks, which can lead to catastrophic downtime and safety incidents.

Protecting Your Process and Equipment

Made from pure, inert PTFE, these gaskets are non-contaminating, non-corrosive, and resistant to a vast range of aggressive chemicals.

This protects the purity of the process medium—critical in pharmaceutical and food industries—and prevents the gasket from degrading, extending its service life. This inertness ensures you replace gaskets less frequently.

Understanding the Trade-offs

To make an informed decision, it's crucial to recognize where ePTFE fits best and what its limitations are.

Initial Material Cost

Expanded PTFE can have a higher initial purchase price compared to some conventional gasket materials like rubber or fiber composites. The cost savings are realized over the lifecycle, not necessarily on the initial invoice.

Application Suitability

The advantages of ePTFE are most pronounced in demanding applications: those involving aggressive chemicals, wide temperature ranges, or irregular flange surfaces found in industries like pharmaceuticals, food processing, and HVAC. For a simple, low-pressure water flange, it may be over-engineered.

Conditional Reusability

While ePTFE gaskets can sometimes be reused, this is typically limited to low-pressure applications. In critical or high-pressure services, it is always best practice to use a new gasket to ensure a reliable seal.

Making the Right Choice for Your Goal

Your primary objective should guide your material selection.

- If your primary focus is minimizing upfront spend: Other materials may offer a lower initial purchase price, but be prepared for potentially higher long-term costs related to maintenance, inventory, and downtime.

- If your primary focus is reducing operational complexity: ePTFE is an excellent choice due to its ability to drastically simplify inventory and speed up on-site installation.

- If your primary focus is ensuring long-term reliability and safety: The superior sealing performance, low creep, and chemical resistance of ePTFE provide the lowest total cost of ownership by preventing costly leaks and failures.

Ultimately, choosing ePTFE is an investment in operational efficiency and long-term system integrity.

Summary Table:

| Cost Advantage | How ePTFE Delivers Savings |

|---|---|

| Inventory & Procurement | One material fits many flange sizes, reducing stock complexity. |

| Installation & Labor | On-site cutting and lower bolt loads speed up installation. |

| Long-Term Reliability | Low creep and excellent surface conformity prevent leaks and downtime. |

| Maintenance | Chemical resistance and stability reduce re-torquing and replacements. |

Ready to reduce your operational costs with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact ePTFE gasket solution to maximize your efficiency and minimize your total cost of ownership.

Contact us today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do PTFE expansion bellows enhance reliability in pharmaceutical manufacturing? Ensure Purity and Uptime

- What temperature range can PTFE-lined butterfly valves withstand? Ensuring Safe & Reliable Operation

- What is the role of PFA in PTFE sheet welding? Key Insights for Seamless Chemical Resistance

- What is a PTFE gasket? The Ultimate Seal for Extreme Chemicals and Temperatures

- What makes PTFE V-rings suitable for sealing applications? Superior Performance in Extreme Conditions

- What are the advantages of using Teflon coatings over liquid lubricants in food processing? Boost Safety & Efficiency

- What are the standard bearing assembly configurations for PTFE slide bearings? Choose the Right PTFE Bearing for Your Project

- What are the applications of Teflon in the automotive industry? Enhance Vehicle Performance & Durability