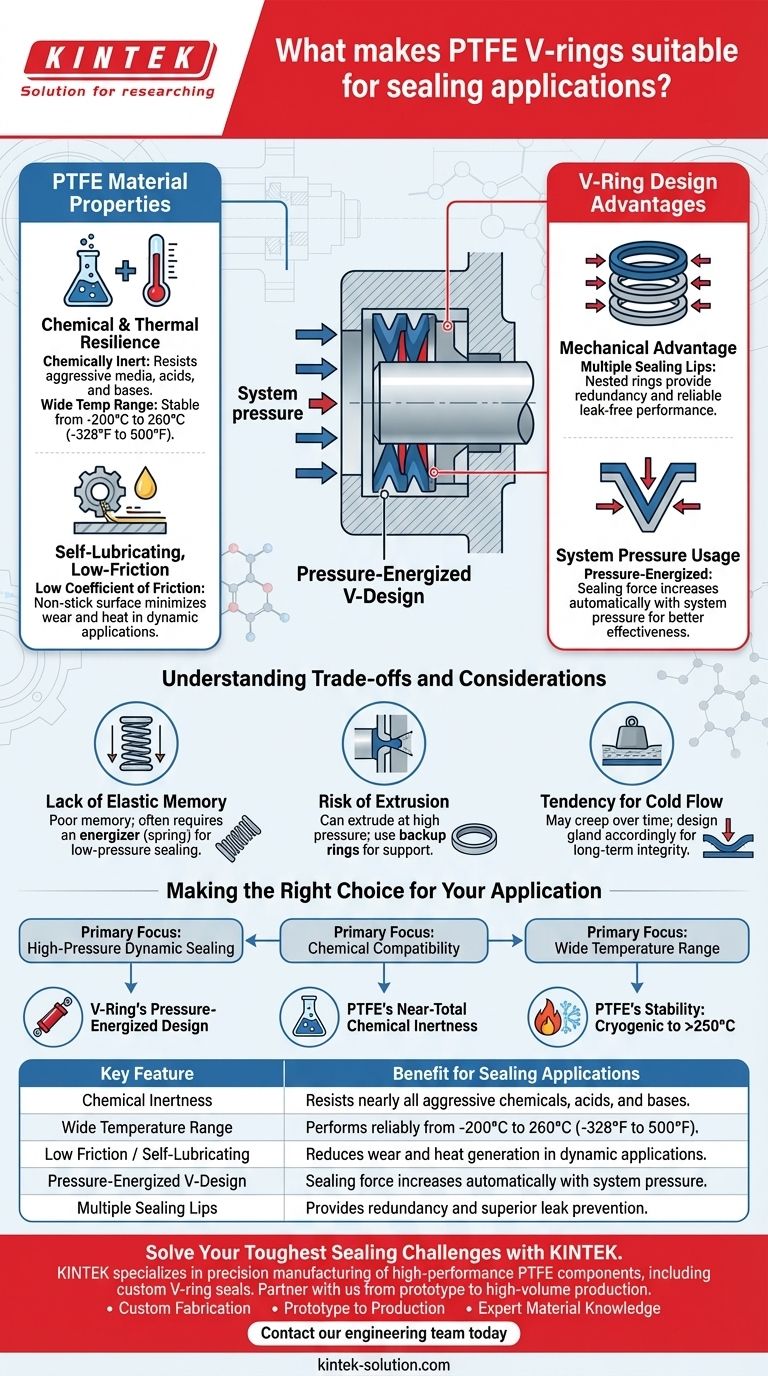

The effectiveness of PTFE V-rings comes from a powerful combination of two factors: the exceptional properties of the Polytetrafluoroethylene (PTFE) material and the mechanical advantage of the V-ring design. This pairing creates a robust sealing solution for demanding applications involving high pressure, extreme temperatures, and aggressive chemicals where standard seals would quickly fail.

The core reason to choose PTFE V-rings is not just for the material itself, but for how the V-shaped, multi-lipped design leverages system pressure to create an increasingly tight seal in environments that are too chemically or thermally hostile for conventional elastomers.

The Two Pillars of Performance: Material and Design

The suitability of a PTFE V-ring seal is best understood by looking at its material properties and its physical shape as two distinct but complementary advantages.

The Chemical and Thermal Resilience of PTFE

PTFE's molecular structure, a chain of carbon atoms shielded by fluorine atoms, creates extremely strong carbon-fluorine bonds. This structure is the source of its legendary performance characteristics.

It is chemically inert, resisting attack from nearly all industrial chemicals, strong acids, and bases. This makes it a default choice for sealing in aggressive media.

Furthermore, PTFE offers outstanding thermal stability, maintaining its properties across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

The Self-Lubricating, Low-Friction Surface

PTFE possesses one of the lowest coefficients of friction of any solid material. This creates a non-stick, self-lubricating surface.

In dynamic applications like sealing a moving piston rod, this property is critical. It minimizes friction and heat generation, reducing wear on both the seal and the equipment and improving overall system efficiency.

The Mechanical Advantage of the V-Ring Shape

A V-ring is not a single ring but a set of nested rings. This design offers significant mechanical benefits over a simple O-ring.

The stack creates multiple sealing lips. Each lip acts as an independent seal, providing redundancy and ensuring a more reliable, leak-free performance, especially in high-pressure hydraulic systems.

How V-Rings Use System Pressure

The "V" shape is engineered to be pressure-energized. As system pressure increases, it acts on the V-shaped profile, forcing the sealing lips more firmly against the rod and housing.

This means that as the operational demands on the seal increase, its sealing effectiveness also increases automatically.

Understanding the Trade-offs and Considerations

While highly effective, PTFE V-rings are not a universal solution. Understanding their limitations is key to successful implementation.

Lack of Elastic Memory

PTFE is a thermoplastic, not a true elastomer like rubber. It has poor "memory," meaning it does not spring back to its original shape effectively after being compressed.

Because of this, V-ring sets are often used with an energizer, such as a spring or an elastomeric component, which provides the initial preload to ensure a tight seal at low pressures.

Risk of Extrusion Under Pressure

PTFE is a relatively soft material. In very high-pressure applications, it can be forced or "extruded" into the small clearance gap between the moving parts.

To prevent this, backup rings are often used alongside the V-ring set. These rings are made of a harder material and sit behind the seal, providing support and preventing extrusion, thus enhancing the system's pressure rating.

Tendency for Cold Flow (Creep)

Under a constant load over time, PTFE can exhibit a tendency to "creep" or slowly deform. This must be considered in the gland design to ensure the long-term integrity of the seal.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its properties to your primary operational challenge.

- If your primary focus is high-pressure dynamic sealing: The V-ring's pressure-energized, multi-lip design offers superior reliability and performance over simpler profiles.

- If your primary focus is chemical compatibility: PTFE's near-total chemical inertness makes it one of the few viable choices for sealing aggressive fluids.

- If your primary focus is a wide temperature range: PTFE's stability from cryogenic levels to over 250°C provides a robust solution where elastomers would certainly fail.

By leveraging PTFE's material strengths with the V-ring's intelligent mechanical design, you can solve some of the most difficult industrial sealing challenges.

Summary Table:

| Key Feature | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists nearly all aggressive chemicals, acids, and bases. |

| Wide Temperature Range | Performs reliably from -200°C to 260°C (-328°F to 500°F). |

| Low Friction / Self-Lubricating | Reduces wear and heat generation in dynamic applications. |

| Pressure-Energized V-Design | Sealing force increases automatically with system pressure. |

| Multiple Sealing Lips | Provides redundancy and superior leak prevention. |

Solve Your Toughest Sealing Challenges with KINTEK

When your application demands a seal that can withstand extreme temperatures, aggressive chemicals, and high pressure, standard elastomers fall short. PTFE V-rings are the engineered solution for these critical environments in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom V-ring seals. We partner with you from prototype to high-volume production to ensure a perfect fit and unparalleled reliability.

Let us provide the sealing solution you need:

- Custom Fabrication: Tailored PTFE seals for your specific application requirements.

- Prototype to Production: Seamless scaling from initial concept to full-scale manufacturing.

- Expert Material Knowledge: Guidance on the optimal seal design for pressure, temperature, and chemical resistance.

Ready to enhance your system's reliability? Contact our engineering team today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining