In the automotive industry, Teflon is primarily used as a high-performance coating for moving parts, a resilient material for seals and gaskets, and a chemically inert lining for fuel system components. Its unique properties help reduce friction in engines, prevent leaks in critical systems, and protect parts from corrosion and wear.

The core reason for Teflon's widespread use in vehicles is not its presence in any single part, but its ability to solve three fundamental engineering challenges: reducing friction, resisting chemical corrosion, and withstanding high temperatures.

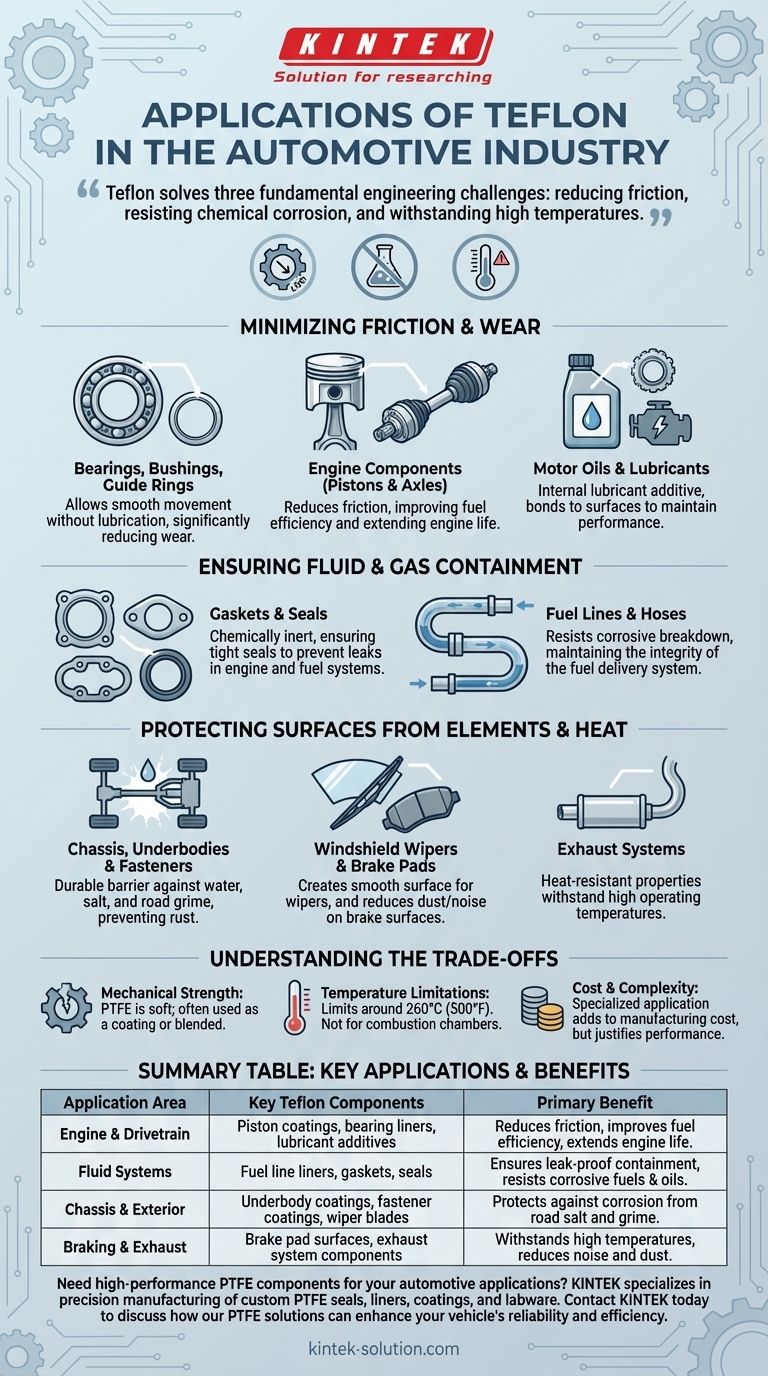

The Core Engineering Problems Teflon Solves

Teflon, or Polytetrafluoroethylene (PTFE), is rarely used for its structural strength. Instead, it is engineered into components to impart specific, highly desirable properties that extend the life and improve the performance of a vehicle.

Minimizing Friction and Wear

The most recognized property of Teflon is its extremely low coefficient of friction. This makes it an ideal material for surfaces that must slide against each other with minimal resistance.

This is applied to bearings, bushings, and guide rings, where a Teflon coating or component allows parts to move smoothly without lubrication, significantly reducing wear and tear over the vehicle's lifespan.

Engine components like pistons and axles are often coated with Teflon. This reduces the energy lost to friction, which can contribute to improved fuel efficiency and a longer service life for the engine's core moving parts.

Teflon is also used as an additive in motor oils and lubricants. It acts as an internal lubricant, bonding to metal surfaces to prevent degradation and maintain performance under the high heat and pressure of a running engine.

Ensuring Fluid and Gas Containment

Automotive fluids like fuel, oil, and brake fluid are often corrosive. Teflon is chemically inert, meaning it does not react with these aggressive substances.

This makes it an excellent material for gaskets and seals. These components are critical for preventing leaks in the engine, transmission, and fuel system, and Teflon's resilience ensures they maintain a tight seal for years.

It is also used to line fuel lines and hoses. The material's resistance to chemical breakdown ensures the integrity of the fuel delivery system, preventing dangerous leaks and contamination.

Protecting Surfaces from Elements and Heat

Teflon's durability extends to protecting components from external environmental factors and internal heat.

As a coating, it is applied to chassis components, underbodies, and fasteners. This provides a durable barrier against water, salt, and road grime, preventing rust and corrosion.

It is even used on windshield wiper blades to create a smooth, non-stick surface that glides effortlessly across the glass, and on brake pad surfaces to help reduce dust and noise.

In exhaust systems, its heat-resistant properties allow it to be used in coatings and components that must withstand high operating temperatures without degrading.

Understanding the Trade-offs

While its benefits are significant, Teflon is not a universal solution. Understanding its limitations is key to appreciating its specific applications.

The Issue of Mechanical Strength

PTFE is a relatively soft material. It cannot be used for load-bearing structural parts on its own. This is why it is almost always applied as a coating, liner, or a component blended with other materials to add strength.

Temperature Limitations

While highly resistant to heat, Teflon has its limits, typically around 260°C (500°F). It is not suitable for the very hottest parts of an engine, such as the inside of a combustion chamber or a turbocharger turbine.

Cost and Application Complexity

Applying Teflon coatings is a specialized industrial process. This adds a layer of complexity and cost to manufacturing compared to using uncoated metal parts. The performance benefits, however, often justify this investment for critical components.

Making the Right Choice for Your Goal

The specific application of Teflon is directly tied to the engineering goal for a particular vehicle system.

- If your primary focus is efficiency and engine longevity: The most important applications are Teflon coatings on pistons, bearings, and its use as an additive in lubricants.

- If your primary focus is reliability and safety: The critical uses are in fuel system hoses, seals, and gaskets, where its chemical inertness prevents leaks.

- If your primary focus is durability and corrosion resistance: Key applications include protective coatings on the chassis, underbody, and exterior fasteners.

Ultimately, Teflon's role in the automotive world is to enhance the performance and durability of other materials, enabling vehicles to run more efficiently and reliably for longer.

Summary Table:

| Application Area | Key Teflon Components | Primary Benefit |

|---|---|---|

| Engine & Drivetrain | Piston coatings, bearing liners, lubricant additives | Reduces friction, improves fuel efficiency, extends engine life |

| Fluid Systems | Fuel line liners, gaskets, seals | Ensures leak-proof containment, resists corrosive fuels & oils |

| Chassis & Exterior | Underbody coatings, fastener coatings, wiper blades | Protects against corrosion from road salt and grime |

| Braking & Exhaust | Brake pad surfaces, exhaust system components | Withstands high temperatures, reduces noise and dust |

Need high-performance PTFE components for your automotive applications?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, coatings, and labware for the automotive, industrial, and specialized manufacturing sectors. We help you solve critical engineering challenges—from reducing friction in moving parts to ensuring chemical resistance in fluid systems.

Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that meet your exact specifications for durability and performance.

Contact KINTEK today to discuss how our PTFE solutions can enhance your vehicle's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech