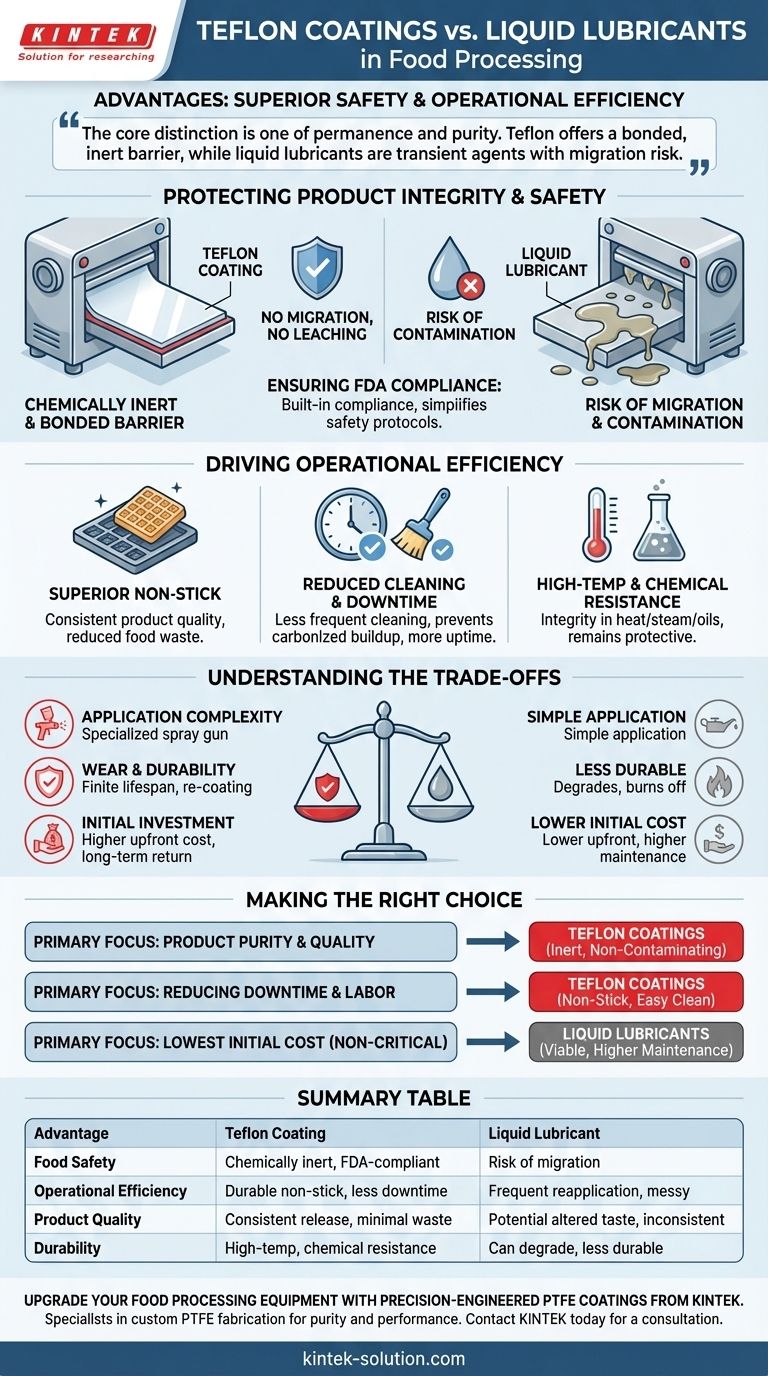

In food processing, the primary advantages of Teflon coatings over liquid lubricants are superior food safety and enhanced operational efficiency. Unlike liquids that can migrate and require constant reapplication, Teflon provides a durable, non-stick surface that is FDA-compliant, does not alter the food's taste or smell, and drastically reduces the cleaning downtime associated with messy liquid alternatives.

The core distinction is one of permanence and purity. Teflon offers a bonded, inert barrier that protects both the product and the process, while liquid lubricants are transient agents that risk migration, contamination, and increased operational friction through residue buildup.

Protecting Product Integrity and Safety

When dealing with consumables, the primary concern is always the purity and safety of the final product. Coatings and lubricants must be evaluated first through this lens.

Eliminating Contamination Risk

Teflon coatings are chemically inert and physically bonded to the equipment surface. This creates a stable barrier that does not leach into or react with food products.

Liquid lubricants, by their nature, are not bonded to the surface. This creates a significant risk of the lubricant migrating from the machine into the food, potentially altering its taste, smell, or consistency.

Ensuring FDA Compliance

Reputable industrial Teflon coatings are specifically formulated to be FDA-compliant for direct food contact. This provides a clear and reliable path for meeting stringent regulatory standards.

This built-in compliance simplifies safety protocols and removes the uncertainty associated with ensuring a liquid lubricant is being applied correctly and not overused.

Driving Operational Efficiency

Beyond safety, the choice of surface treatment has a direct and significant impact on production uptime, labor costs, and material waste.

Superior Non-Stick and Release Properties

The defining characteristic of Teflon is its excellent non-stick surface. In food processing, this means sticky substances like dough, batter, or cheese release cleanly from molds, trays, and conveyor belts.

This ensures consistent product shape and quality—from ice cream cones to waffles—and dramatically reduces food waste caused by products adhering to machinery.

Reducing Cleaning and Downtime

Equipment with Teflon coatings requires far less frequent and less intensive cleaning. The easy-release properties prevent the carbonized buildup that plagues machinery using liquid lubricants.

This translates directly into less production downtime, reduced labor costs for sanitation, and enables more continuous, efficient operation.

High-Temperature and Chemical Resistance

Teflon coatings maintain their integrity across a wide range of temperatures. They do not degrade or burn off when exposed to the heat of baking or cooking.

They are also highly resistant to hot water, steam, oils, and fats, ensuring the coating remains effective and protective throughout demanding processing cycles.

Understanding the Trade-offs

While advantageous, Teflon coatings are not a universal solution. An objective assessment requires understanding their specific implementation requirements and limitations.

Application Complexity

Applying a Teflon coating is a specialized industrial process. It requires professional surface preparation, spraying, and high-temperature curing that cannot be done on-site like simply applying a food-grade oil.

Wear and Durability

Industrial coatings have a finite lifespan. While highly durable, they can be damaged by severe abrasion or improper handling with metal utensils, eventually requiring the equipment to be sent out for re-coating.

Initial Investment

The upfront cost to have equipment professionally coated with Teflon is typically higher than purchasing a drum of liquid lubricant. The return on this investment is realized over time through reduced downtime, labor savings, and lower product waste.

Making the Right Choice for Your Process

To determine the best solution, evaluate your primary operational drivers and pain points.

- If your primary focus is maximizing product purity and ensuring consistent quality: Teflon coatings are the superior choice due to their inert, non-contaminating nature.

- If your primary focus is reducing operational downtime and labor costs: The significant reduction in cleaning requirements from Teflon's non-stick properties provides a clear long-term advantage.

- If your primary focus is the lowest possible initial cost for non-critical applications: Food-grade liquid lubricants can remain a viable, albeit higher-maintenance, option.

Ultimately, choosing the right surface treatment is a strategic decision that directly impacts your product's quality and your plant's long-term efficiency.

Summary Table:

| Advantage | Teflon Coating | Liquid Lubricant |

|---|---|---|

| Food Safety | Chemically inert, FDA-compliant, no migration risk | Risk of migration and contamination |

| Operational Efficiency | Durable non-stick surface, reduces cleaning & downtime | Requires frequent reapplication, messy residue |

| Product Quality | Consistent release, minimal food waste | Potential for altered taste/smell, inconsistent results |

| Durability | High-temperature and chemical resistance | Can degrade or burn off, less durable |

Upgrade your food processing equipment with precision-engineered PTFE coatings from KINTEK.

As specialists in custom PTFE fabrication for the food, semiconductor, medical, and laboratory industries, we understand the critical need for purity and performance. Our high-quality PTFE coatings provide a permanent, FDA-compliant, non-stick solution that protects your product integrity and boosts your operational efficiency by reducing downtime and waste.

Whether you need a prototype or a high-volume order, we deliver precision and reliability. Let's discuss how our PTFE components can enhance your process.

Contact KINTEK today for a consultation and see the difference a superior coating makes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments