In short, the most common standard sizes for ePTFE sheets are 1000x1000 mm, 1200x1200 mm, and 1500x1500 mm. These dimensions are the industry-standard raw formats from which custom gaskets and seals are typically fabricated.

While knowing the standard sheet dimensions is a necessary starting point, your true goal is to solve a sealing challenge. The size of the sheet is simply a logistical constraint; the material's unique properties and thickness are the variables that will determine the success of your application.

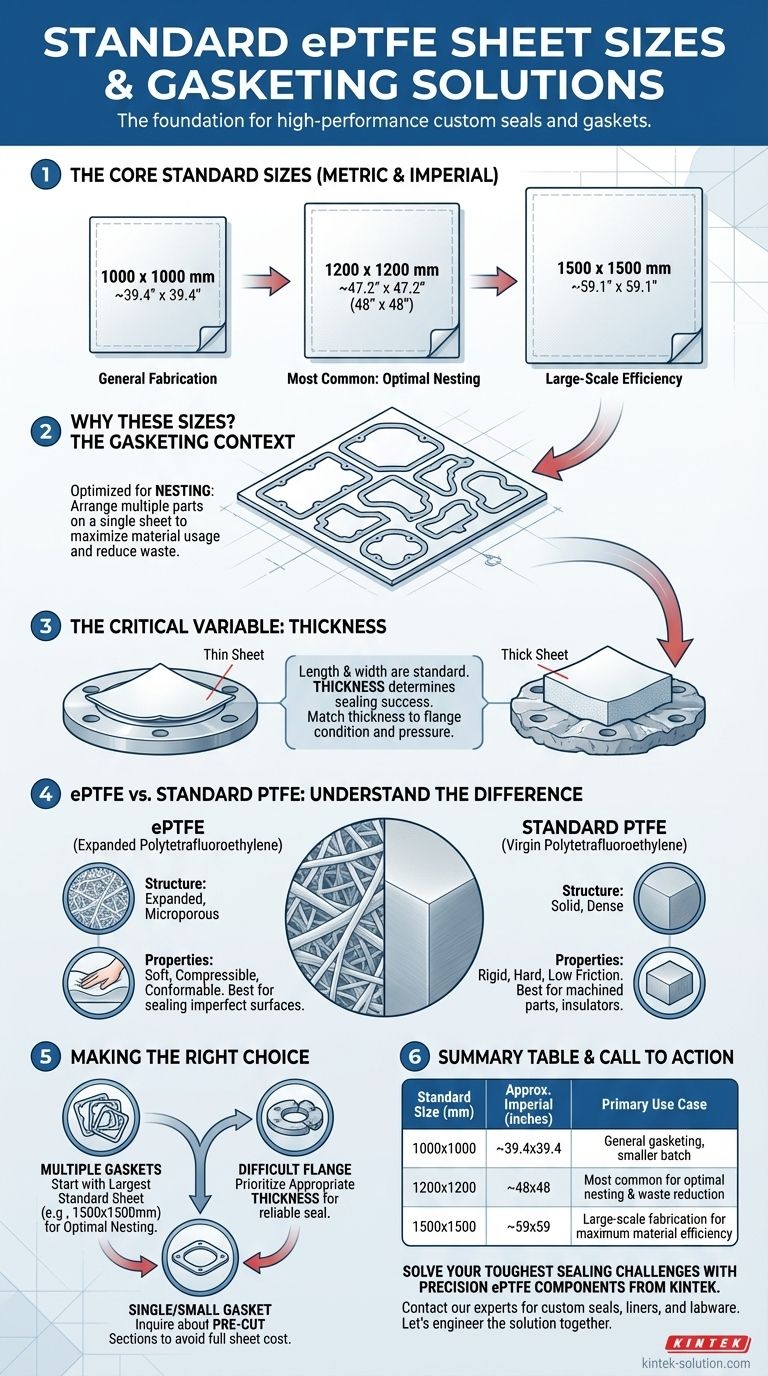

Deconstructing ePTFE Sheet Dimensions

Expanded Polytetrafluoroethylene (ePTFE) is a specialized material, and its sizing reflects its primary use case: high-performance gasketing. The standard dimensions are designed for efficiency in this context.

The Metric Standard

The most widely cited and available sizes for ePTFE sheets are square and based on the metric system.

You will consistently find these three dimensions from major suppliers:

- 1000 mm x 1000 mm (~39.4" x 39.4")

- 1200 mm x 1200 mm (~47.2" x 47.2")

- 1500 mm x 1500 mm (~59.1" x 59.1")

These sizes represent the raw stock material.

Imperial Equivalents and Common Variations

In markets that primarily use the imperial system, like the United States, you may see sizes quoted in inches.

Most often, these are simply rounded-up equivalents of the metric standard. A 1200x1200 mm sheet is often listed as 48 x 48 inches, as it's a close and familiar measurement.

Why These Sizes? The Gasketing Context

The large, square format is not arbitrary. It is optimized for fabricating custom gaskets.

This format allows for nesting, a process where multiple, often complex, gasket shapes are arranged on a single sheet to maximize material usage and dramatically reduce waste.

The Critical Role of Thickness

While length and width are standardized, thickness is a critical design variable that you must specify.

The required thickness depends entirely on the application, particularly the condition of the flange surfaces and the internal pressure. A rougher or more warped flange requires a thicker, more conformable sheet to create a reliable seal.

Understanding the Trade-offs: ePTFE vs. Standard PTFE

It is crucial not to confuse ePTFE with standard, or virgin, PTFE. While they share the same base chemistry, their physical properties and common form factors are different.

The "e" Makes the Difference

The "e" stands for expanded. During manufacturing, ePTFE is stretched, creating a microporous, fibrous structure. This makes it significantly softer and more compressible than solid PTFE.

This softness allows ePTFE to conform to and seal imperfect surfaces where a rigid material would fail.

Sizing and Form Factor

Standard PTFE is a rigid plastic available in a wider variety of shapes and sizes, including sheets, rods, and tubes. A common sheet size for standard PTFE is 48" x 48", but it is available in a much broader range of thicknesses, from 0.031" to over 4".

ePTFE is almost exclusively sold as a soft gasketing sheet in the standard sizes mentioned, or as a flexible sealing tape on a spool.

Implications for Your Application

Choose ePTFE when your primary goal is creating a superior seal, especially on irregular, damaged, or fragile flanges (like glass-lined or plastic vessels).

Choose standard PTFE when you need a rigid, low-friction, chemically inert material for a machined part, an insulator, or a structural component.

Making the Right Choice for Your Goal

Selecting the correct sheet starts with understanding your project's primary driver.

- If your primary focus is producing multiple custom gaskets: Start with the largest standard sheet your fabrication equipment can handle (e.g., 1500x1500 mm) to optimize nesting and minimize scrap.

- If your primary focus is sealing a difficult or damaged flange: Prioritize selecting the appropriate material thickness to ensure the ePTFE can fill surface imperfections and create a reliable seal.

- If your primary focus is a single, small gasket: Inquire with suppliers about purchasing pre-cut sections, as many will cut down their standard sheets for smaller jobs to save you from buying a full sheet.

Understanding the standard sizes is the first step; matching the material's properties to your specific sealing challenge is what ensures engineering success.

Summary Table:

| Standard Sheet Size (mm) | Approximate Imperial Equivalent (inches) | Primary Use Case |

|---|---|---|

| 1000 x 1000 | ~39.4" x 39.4" | General gasketing, smaller batch fabrication |

| 1200 x 1200 | ~48" x 48" | Most common size for optimal nesting and waste reduction |

| 1500 x 1500 | ~59" x 59" | Large-scale fabrication for maximum material efficiency |

Solve your toughest sealing challenges with precision ePTFE components from KINTEK.

You've identified the standard sheet sizes, but the real key to success is selecting the right material properties and thickness for your specific application—whether it's for a damaged flange, a high-purity semiconductor process, or a critical medical device.

KINTEK specializes in manufacturing high-performance PTFE and ePTFE components (seals, liners, gaskets, and custom labware) for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication expertise, guiding you from prototype to high-volume production to ensure a perfect seal every time.

Let's engineer the solution together. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key properties that make PTFE an effective sealing material? Unlock Superior Performance in Harsh Environments

- What are some common structural types of PTFE gaskets? Choose the Right Seal for Your Application

- In which industries are PTFE diaphragms commonly used? For Superior Chemical Resistance and Purity

- When should PTFE bellows be chosen over other materials? Maximize System Purity and Chemical Resistance

- What are the performance benefits of PTFE lined butterfly valves? Achieve Superior Corrosion Resistance & Zero Leakage

- In what types of industrial applications are PTFE-lined butterfly valves versatile? Handle Aggressive & Pure Media

- How does the shrinkage performance of PTFE gaskets affect their functionality? Ensure a Perfect, Leak-Free Seal

- Why is the manufacturing cost of PTFE processing machines high? The Engineering Behind High-Performance Polymer Processing