PTFE-lined butterfly valves are a cornerstone of modern industrial fluid control, serving a vast range of applications from chemical processing and pharmaceuticals to water treatment and food production. Their versatility is due to the unique properties of Polytetrafluoroethylene (PTFE), which provides an inert, non-contaminating barrier for nearly any type of media, including aggressive chemicals, high-purity liquids, gases, and even slurries.

The core reason for the versatility of PTFE-lined butterfly valves is not a single feature, but a powerful combination of near-universal chemical inertness, a high-purity non-stick surface, and reliable sealing capabilities. This unique trifecta makes them a go-to solution for the most demanding fluid handling challenges.

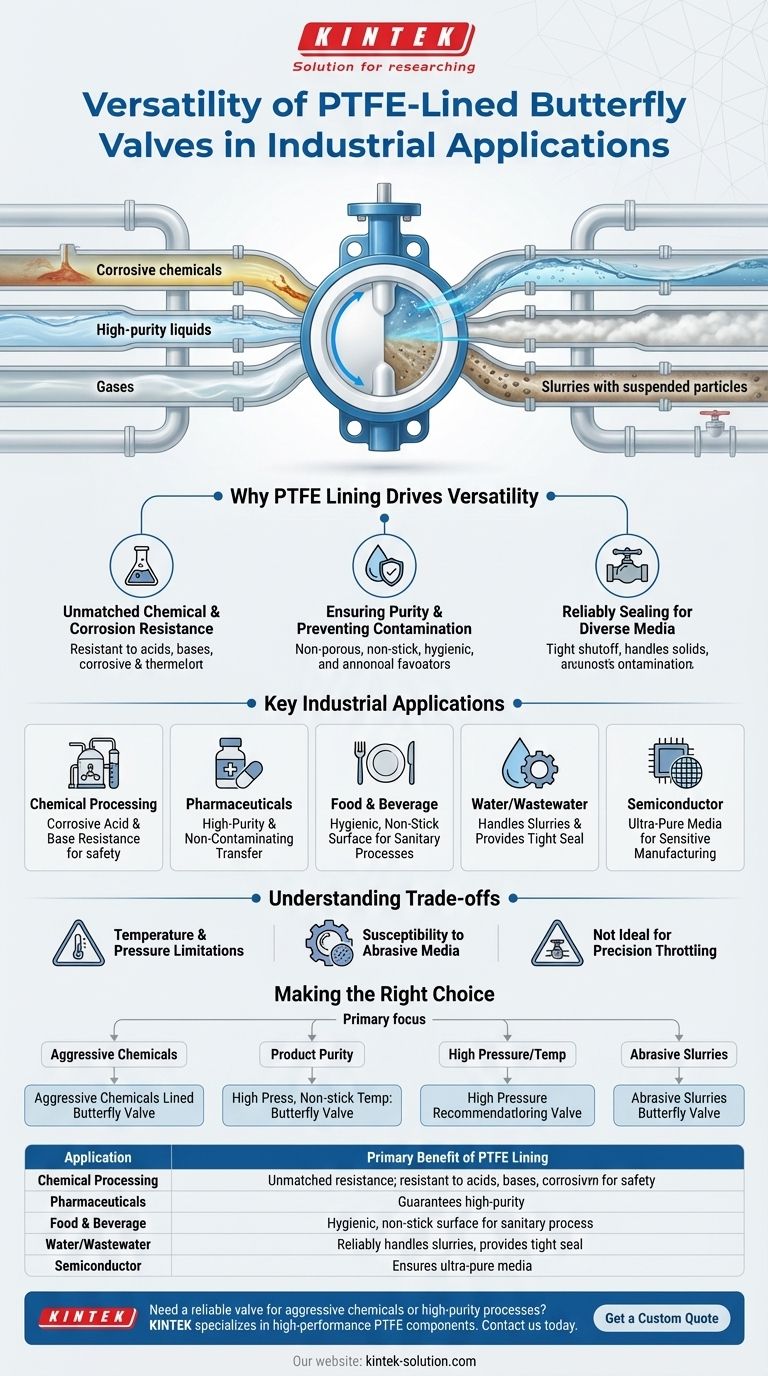

Why PTFE Lining Drives Versatility

The valve's utility isn't defined by its butterfly mechanism alone, but by the performance of its PTFE liner. This inert polymer lining isolates the valve body from the process media, unlocking its use across diverse and challenging environments.

Unmatched Chemical and Corrosion Resistance

PTFE is one of the most chemically inert substances known, making it resistant to nearly all corrosive chemicals, acids, and bases. This makes it an essential component in managing aggressive and toxic media safely.

This property is critical in industries like chemical processing, petrochemicals, and environmental protection, where equipment longevity and the prevention of hazardous leaks are paramount.

Ensuring Purity and Preventing Contamination

The surface of PTFE is non-porous, non-stick, and does not leach contaminants into the process media. This ensures that the fluid remains pure and unaltered as it passes through the valve.

This is a non-negotiable requirement in the pharmaceutical, food and beverage, and semiconductor manufacturing industries, where even trace amounts of contamination can ruin an entire product batch.

Reliable Sealing for Diverse Media

PTFE-lined valves provide a tight shutoff, effectively sealing pipes to prevent both internal system leakages and fugitive emissions into the atmosphere. This robust sealing works reliably with gases, liquids, and even slurries with suspended particles.

Their ability to handle media with solids makes them suitable for applications in wastewater treatment, paper manufacturing, and mining operations, where other valve types might clog or fail.

Understanding the Trade-offs

While highly versatile, PTFE-lined valves are not a universal solution. Understanding their operational limits is key to proper application and avoiding premature failure.

Temperature and Pressure Limitations

PTFE is a polymer and has a lower operating temperature and pressure ceiling compared to metal-seated valves. Exceeding these manufacturer-specified limits can lead to liner deformation and seal failure.

Susceptibility to Abrasive Media

While they can handle slurries, highly abrasive media can mechanically wear down the soft PTFE liner over time. In applications with sharp, hard particulates, this can compromise the valve's sealing integrity.

Not Ideal for Precision Throttling

Butterfly valves are generally best suited for on/off or modulating control applications. While they can be used for throttling, they may not provide the fine-tuned, linear flow control achievable with other designs like globe valves, especially at low flow rates.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its strengths to your primary operational goal.

- If your primary focus is handling aggressive chemicals: The near-universal inertness of PTFE makes these valves an industry standard for safety and reliability.

- If your primary focus is product purity: The non-contaminating and hygienic properties of a PTFE liner are essential for applications in pharmaceuticals, food, and semiconductors.

- If your primary focus is high-pressure or high-temperature service: You must verify that your operating conditions are well within the valve's specified limits and consider a metal-seated valve if they are not.

- If your primary focus is handling abrasive slurries: While capable, you must consider potential liner wear and evaluate if a more robust valve type, like a knife gate or pinch valve, is better suited for long-term service.

By understanding these core strengths and limitations, you can deploy PTFE-lined butterfly valves with precision and confidence in your system.

Summary Table:

| Application | Primary Benefit of PTFE Lining |

|---|---|

| Chemical Processing | Unmatched resistance to corrosive acids and bases. |

| Pharmaceuticals | Guarantees high-purity, non-contaminating fluid transfer. |

| Food & Beverage | Provides a hygienic, non-stick surface for sanitary processes. |

| Water/Wastewater | Reliably handles slurries and provides a tight seal. |

| Semiconductor | Ensures ultra-pure media for sensitive manufacturing. |

Need a reliable valve for aggressive chemicals or high-purity processes?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-fabricated seals and liners for industrial valves. Our expertise in precision PTFE fabrication ensures your equipment meets the demanding standards of the semiconductor, medical, laboratory, and chemical industries.

We partner with you from prototype to high-volume production to deliver the exact solution you need. Contact us today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts