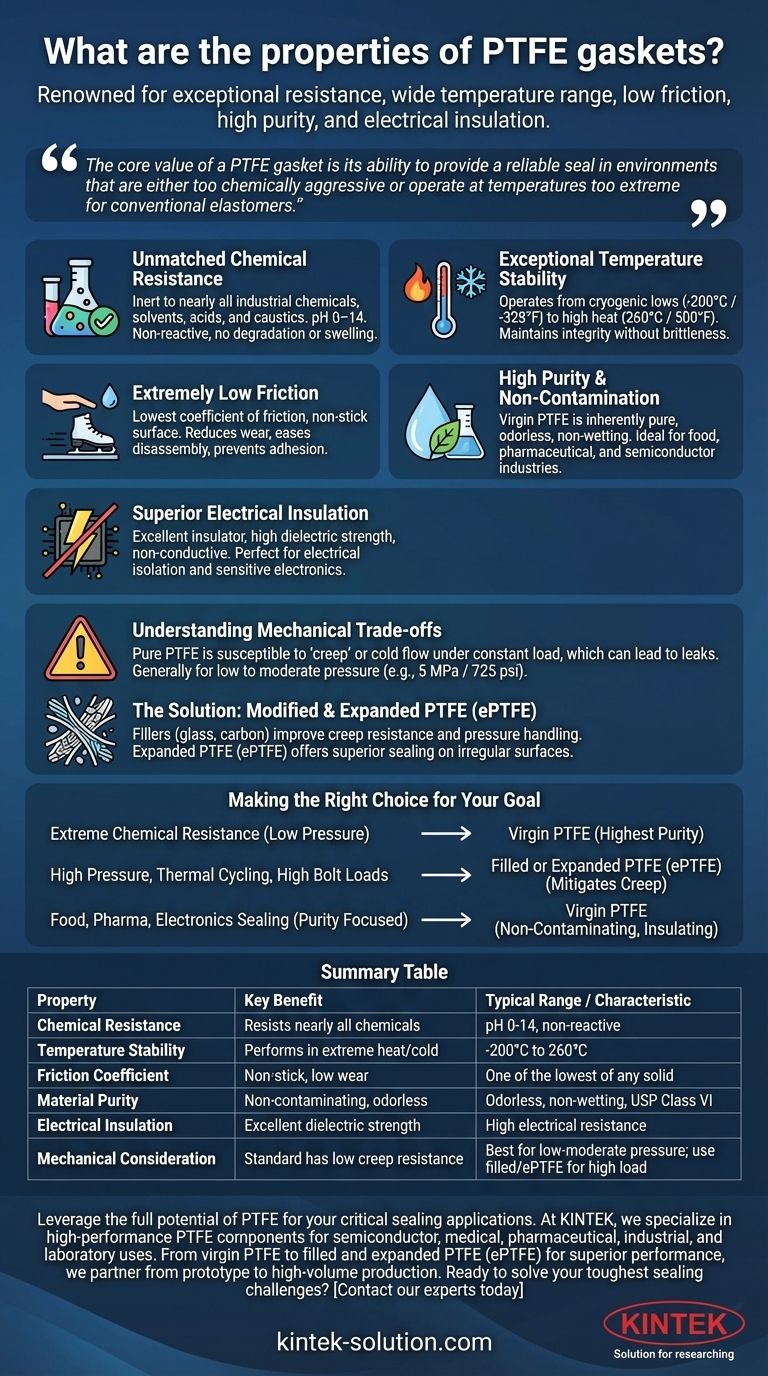

PTFE gaskets are renowned for five principal properties: exceptional chemical resistance, a very wide operational temperature range, an extremely low coefficient of friction, high material purity, and excellent electrical insulation. This unique combination makes them a critical sealing solution for demanding industrial, chemical, and electronic applications where other materials would quickly fail.

The core value of a PTFE gasket is its ability to provide a reliable seal in environments that are either too chemically aggressive or operate at temperatures too extreme for conventional elastomers. However, understanding the mechanical limitations of pure PTFE is crucial for selecting the right variant for your specific pressure and load requirements.

The Core Properties of PTFE in Detail

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer with a unique molecular structure that gives rise to its valuable characteristics as a gasket material.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. It is non-reactive and can withstand nearly all industrial chemicals, solvents, acids, and caustic solutions across the entire pH range of 0–14.

This property means the gasket will not degrade, swell, or contaminate the process media, ensuring the integrity of both the seal and the product.

Exceptional Temperature Stability

PTFE gaskets perform reliably across an exceptionally broad temperature spectrum, typically from cryogenic lows of -200°C (-328°F) up to high-heat applications of 260°C (500°F).

This allows them to be used in processes involving extreme temperature fluctuations without becoming brittle or losing their sealing capability.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This results in a non-stick, non-adhesive surface.

This low-friction property reduces wear on the sealing surfaces, makes disassembly for maintenance easier, and prevents the gasket from adhering to flange faces.

High Purity and Non-Contamination

Virgin PTFE is inherently pure, non-contaminating, odorless, and non-wetting. It does not impart any taste or odor to the materials it contacts.

This makes it an ideal sealing solution for sensitive applications in the food, pharmaceutical, and semiconductor industries where process purity is paramount.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength and very low electrical conductivity.

This non-conductive nature makes it a perfect choice for applications that require electrical isolation, such as in sensitive electronic components, circuit boards, and other electrical equipment.

Understanding the Mechanical Trade-offs

While PTFE's chemical and thermal properties are outstanding, it is essential to understand the mechanical limitations of its pure, or "virgin," form.

The Challenge of "Creep" or Cold Flow

Standard virgin PTFE can be susceptible to creep, also known as cold flow. This is the tendency for the material to slowly deform over time when under a constant compressive load, such as the pressure from flange bolts.

This deformation can lead to a loss of bolt torque and a potential leak path, particularly in applications with high pressure or significant temperature cycling.

Pressure Limitations

Due to its relative softness and susceptibility to creep, pure PTFE gaskets are generally best suited for low to moderate pressure applications. Some sources note pressure limits around 5 MPa (725 psi) for standard gaskets.

The Solution: Modified and Expanded PTFE

To overcome these mechanical weaknesses, manufacturers produce filled, modified, and expanded PTFE (ePTFE) gaskets.

Fillers like glass, carbon, or silica are added to virgin PTFE to dramatically improve its resistance to creep and increase its pressure handling capabilities. Expanded PTFE has a multi-directional fibrous structure that provides superior sealing on irregular surfaces and much better creep resistance.

Making the Right Choice for Your Goal

Selecting the correct PTFE gasket requires matching the material's properties to the mechanical and chemical demands of your application.

- If your primary focus is extreme chemical resistance in low-pressure systems: Standard virgin PTFE offers the highest purity and is an excellent, cost-effective choice.

- If your application involves high pressure, thermal cycling, or high bolt loads: A filled or expanded PTFE (ePTFE) gasket is necessary to mitigate creep and ensure a durable, long-term seal.

- If your primary focus is sealing in food, pharmaceutical, or electronics manufacturing: Virgin PTFE is the ideal choice due to its non-contaminating and electrically insulating properties.

By matching the specific type of PTFE to your application's demands, you can fully leverage its exceptional material properties for a safe and reliable seal.

Summary Table:

| Property | Key Benefit | Typical Range / Characteristic |

|---|---|---|

| Chemical Resistance | Resists nearly all industrial chemicals | pH 0-14, non-reactive |

| Temperature Stability | Performs in extreme heat and cold | -200°C to 260°C (-328°F to 500°F) |

| Friction Coefficient | Non-stick, low wear, easy disassembly | One of the lowest of any solid |

| Material Purity | Non-contaminating, ideal for sensitive processes | Odorless, non-wetting, USP Class VI |

| Electrical Insulation | Excellent dielectric strength, non-conductive | High electrical resistance |

| Mechanical Consideration | Standard PTFE has low creep resistance | Best for low-moderate pressure; use filled/ePTFE for high load |

Leverage the full potential of PTFE for your critical sealing applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including gaskets, seals, liners, and custom labware. Whether your industry is semiconductor, medical, pharmaceutical, industrial, or laboratory, we provide the right PTFE solution—from virgin PTFE for ultimate purity to filled and expanded PTFE (ePTFE) for superior creep resistance and high-pressure performance.

We partner with you from prototype to high-volume production, ensuring a perfect seal for your specific chemical, temperature, and mechanical requirements.

Ready to solve your toughest sealing challenges? Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when choosing between pure PTFE and additive-enhanced PTFE in valve manufacturing? Optimize Performance and Purity

- What are the special features of PTFE that make it suitable for medical applications? Unlock Superior Biocompatibility & Performance

- What are the common characteristics of PTFE and Graphite packing materials? Key Similarities and Critical Differences

- What are the advantages of PTFE slide bearings over conventional supports? Achieve Frictionless Movement for Durable Structures

- How do spring-energized PTFE seals contribute to energy efficiency? Minimize Friction and Reduce Energy Waste

- What are the main properties of PTFE gaskets? Unlock Superior Sealing in Extreme Conditions

- Why is a thin element design preferred for PTFE seals from a cost standpoint? Minimize Initial Cost & Maximize Long-Term Value

- What makes ePTFE gaskets effective against gas leakage? The Key to Superior Gas Sealing