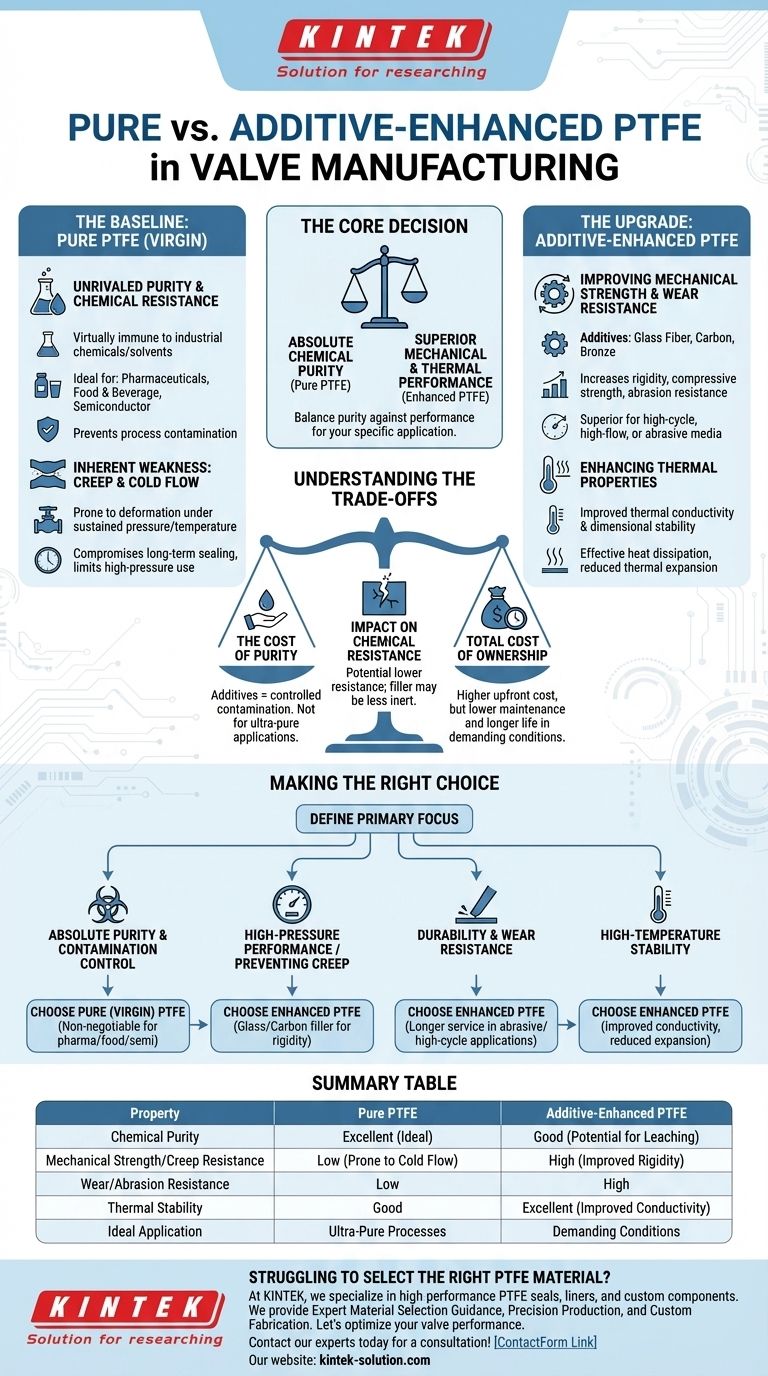

The choice between pure PTFE and additive-enhanced PTFE for valve components is a critical engineering decision that balances the absolute chemical purity of the former against the superior mechanical and thermal performance of the latter. Pure PTFE is the default choice for applications where contamination is unacceptable, while enhanced PTFE is specified for demanding conditions involving high pressure, temperature, or abrasion.

The core decision is not about which material is universally better, but which properties are non-negotiable for your specific application. You must choose between the unmatched purity of pure PTFE and the enhanced strength, wear resistance, and thermal stability offered by additive-filled grades.

The Baseline: Understanding Pure PTFE

Pure Polytetrafluoroethylene (PTFE), often referred to as virgin PTFE, is renowned for one primary characteristic: its extreme chemical inertness. It serves as the benchmark against which other materials are measured for purity and non-reactivity.

### Unrivaled Purity and Chemical Resistance

Pure PTFE is one of the most chemically resistant materials known. It is virtually immune to all industrial chemicals and solvents, making it the ideal choice for handling highly corrosive or sensitive media.

This property makes it indispensable in industries like pharmaceuticals, food and beverage, and semiconductor manufacturing, where preventing process contamination is the highest priority.

### The Inherent Weakness: Creep and Cold Flow

The primary drawback of pure PTFE is its softness and tendency to "creep" or cold flow. Under sustained pressure and temperature, the material can deform permanently, which can compromise a valve's seal over time.

This limits its effectiveness in high-pressure applications or where tight, consistent sealing is required over long service cycles.

The Upgrade: How Additives Enhance PTFE

To overcome the mechanical limitations of pure PTFE, various filler materials are added to the polymer matrix. These additives fundamentally change the material's behavior, making it suitable for a much wider range of demanding industrial applications.

### Improving Mechanical Strength and Wear Resistance

Additives like glass fiber, carbon, or bronze dramatically increase the material's rigidity, compressive strength, and resistance to wear and abrasion.

This enhancement makes it a superior choice for valve seats and seals that are subject to frequent cycling, high flow rates, or abrasive media.

### Enhancing Thermal Properties

Enhanced PTFE grades exhibit improved thermal conductivity and dimensional stability at higher temperatures compared to pure PTFE.

This allows heat to dissipate more effectively, reducing thermal expansion and improving the material's performance and sealing integrity under demanding thermal conditions.

Understanding the Trade-offs

Selecting an additive-enhanced PTFE introduces new variables that must be carefully considered. The performance gains in one area often come with compromises in another.

### The Cost of Purity

The primary trade-off is purity. By definition, additives are a form of controlled contamination. While they enhance mechanical properties, they are not suitable for ultra-pure applications where any leaching from the filler material is unacceptable.

### Potential Impact on Chemical Resistance

While still excellent, the chemical resistance of some enhanced PTFE grades can be slightly lower than that of pure PTFE. The filler material itself may not share PTFE's near-universal inertness, creating a potential point of chemical attack in highly aggressive environments.

### Total Cost of Ownership

Enhanced PTFE components may have a higher upfront cost. However, their superior durability and longer service life in demanding applications can lead to a lower total cost of ownership by reducing valve maintenance, replacement frequency, and costly downtime.

Making the Right Choice for Your Application

Your final decision must be guided by the primary operational demand of the valve. The following guidelines will help you select the appropriate material.

- If your primary focus is absolute purity and contamination control: Choose pure (virgin) PTFE. This is non-negotiable for pharmaceutical, food-grade, or semiconductor processes.

- If your primary focus is high-pressure performance or preventing creep: Choose an additive-enhanced PTFE with a filler like glass or carbon for improved rigidity.

- If your primary focus is durability and wear resistance: Choose an additive-enhanced PTFE, as it will provide a significantly longer service life in abrasive or high-cycle applications.

- If your primary focus is high-temperature stability: Choose an additive-enhanced PTFE to benefit from improved thermal conductivity and reduced thermal expansion.

By clearly defining your application's most critical requirement, you can confidently select the material that ensures optimal valve performance, reliability, and safety.

Summary Table:

| Property | Pure PTFE | Additive-Enhanced PTFE |

|---|---|---|

| Chemical Purity | Excellent (Ideal) | Good (Potential for Leaching) |

| Mechanical Strength / Creep Resistance | Low (Prone to Cold Flow) | High (Improved Rigidity) |

| Wear / Abrasion Resistance | Low | High |

| Thermal Stability | Good | Excellent (Improved Conductivity) |

| Ideal Application | Ultra-Pure Processes (Pharma, Food, Semiconductor) | Demanding Conditions (High Pressure, Temperature, Abrasion) |

Struggling to select the right PTFE material for your critical valve components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the optimal balance of purity, strength, and durability for your specific application.

We provide:

- Expert Material Selection Guidance: Leverage our deep knowledge of PTFE properties to avoid costly mistakes.

- Precision Production: From prototypes to high-volume orders, we prioritize quality and consistency.

- Custom Fabrication: Get components tailored to your exact specifications and performance requirements.

Let's optimize your valve performance and reliability. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation