At its core, the suitability of Polytetrafluoroethylene (PTFE) for medical applications stems from a unique combination of three key features: its profound biological inertness, high resistance to chemicals, and an exceptionally low coefficient of friction. This makes the material non-reactive with human tissue, resilient to aggressive sterilization processes, and ideal for devices that must move smoothly within the body.

The critical insight is that PTFE is not valued for a single trait, but for the powerful synergy of its properties. Its ability to be both completely non-reactive with the body and functionally superior as a non-stick, durable material makes it a cornerstone of modern medical device design.

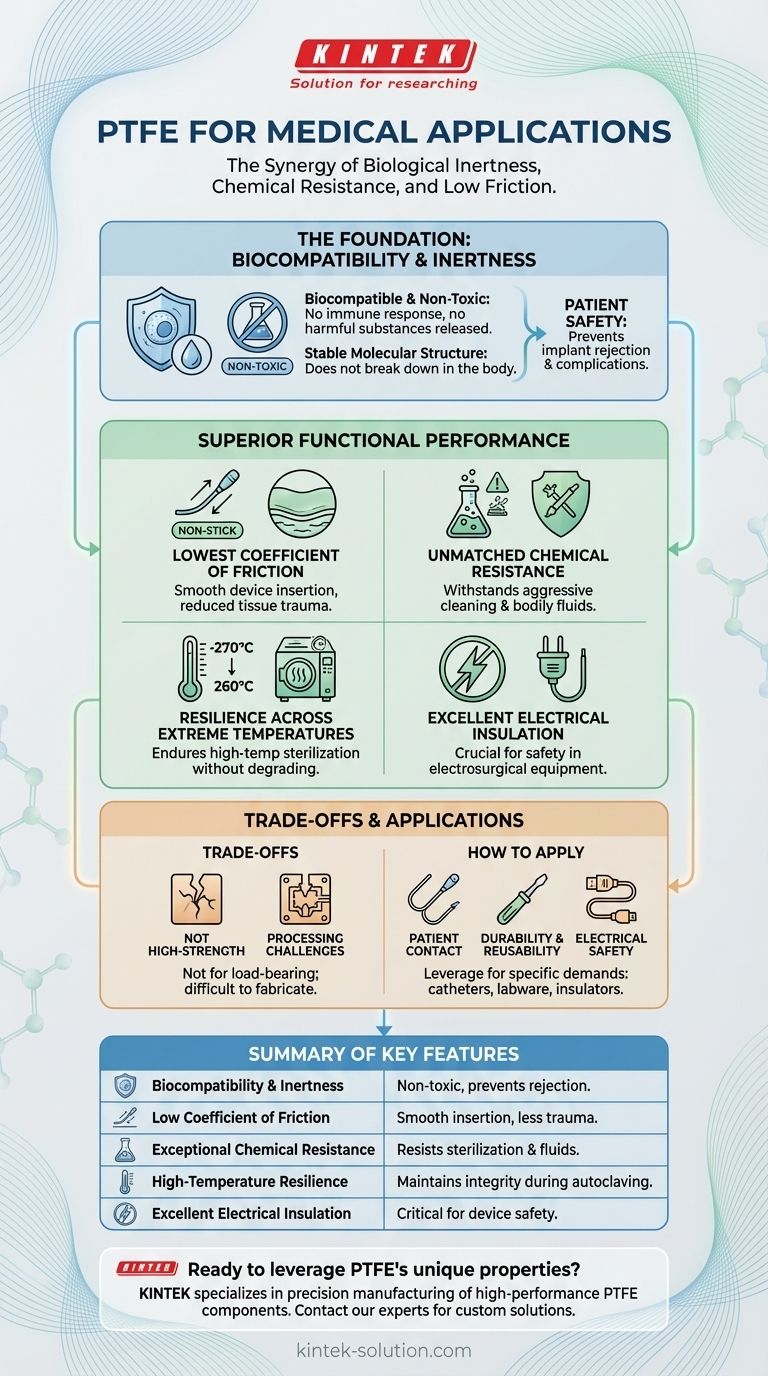

The Foundation: Biocompatibility and Chemical Inertness

The most critical requirement for any material used inside the human body is that it causes no harm. PTFE excels in this area due to its complete chemical and biological inertness.

What "Inert" Means in a Medical Context

PTFE is biocompatible and non-toxic. This means it does not trigger an immune response, cause allergic reactions, or release harmful substances when it comes into direct contact with blood, tissue, or other bodily fluids.

Its molecular structure is incredibly stable, preventing it from reacting with or breaking down in the body's complex chemical environment.

The Direct Impact on Patient Safety

This inert behavior is fundamental to patient safety. For implants, it prevents the body from rejecting the device. For tools like catheters and sutures, it ensures that the material itself doesn't introduce complications during or after a procedure.

Superior Functional Performance in Medical Devices

Beyond just being safe, a medical material must perform its function reliably. PTFE’s physical properties provide distinct advantages for a wide range of medical equipment.

The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid, giving it exceptional non-stick properties. This is vital for devices like catheters, which must be inserted into the body with minimal trauma to surrounding tissues.

This "slipperiness" also benefits coatings on surgical instruments, ensuring smooth and precise operation.

Unmatched Chemical Resistance

Medical devices must withstand not only bodily fluids but also aggressive cleaning agents and sterilization procedures. PTFE's high chemical resistance ensures it will not degrade or corrode, maintaining the integrity and safety of the device over its lifespan.

Resilience Across Extreme Temperatures

PTFE maintains its properties across a vast thermal range, from approximately -270°C to 260°C. This robustness allows devices made from it to endure high-temperature sterilization methods, a critical step in preventing infection.

Its flexibility, even at very low temperatures, is also a valuable characteristic for certain specialized applications.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator, or dielectric. This property is crucial for components in electrosurgical machinery and other medical equipment where preventing electrical current from reaching the patient or operator is a primary safety concern.

Understanding the Trade-offs

While PTFE's advantages are significant, it is not the ideal solution for every medical application. Acknowledging its limitations is key to using it effectively.

Not a High-Strength Structural Material

PTFE is a relatively soft polymer. It is not suitable for load-bearing applications like primary joint replacements that require the high mechanical strength of metals or other advanced polymers. It is most often used as a coating, liner, or component where its unique surface and chemical properties are needed.

Fabrication and Processing Challenges

PTFE has a high melting point and viscosity, which can make it more difficult and costly to process into complex shapes compared to more common thermoplastics. This is a critical consideration during the device design and manufacturing phases.

How to Apply PTFE to Your Project

Your choice to use PTFE should be driven by the specific demands of the medical device you are developing.

- If your primary focus is patient-contact surfaces: Leverage PTFE for its biocompatibility and low-friction properties in devices like catheters, guidewires, and surgical sutures.

- If your primary focus is device durability and reusability: Utilize its chemical and thermal resistance for components in life-saving machinery, bio-containment vessels, and reusable surgical tools that undergo frequent sterilization.

- If your primary focus is electrical safety: Specify PTFE for its superior dielectric properties as an insulator in cables and components for electrosurgical and diagnostic equipment.

Ultimately, PTFE's unique combination of inertness and high performance makes it a foundational material for creating safer and more effective medical devices.

Summary Table:

| Key Feature | Why It Matters for Medical Applications |

|---|---|

| Biocompatibility & Inertness | Non-toxic, non-allergenic; prevents immune response and tissue rejection. |

| Low Coefficient of Friction | Enables smooth insertion of catheters and reduces tissue trauma. |

| Exceptional Chemical Resistance | Withstands aggressive sterilization and harsh bodily fluids. |

| High-Temperature Resilience | Maintains integrity during autoclaving and other sterilization processes. |

| Excellent Electrical Insulation | Critical for safety in electrosurgical and diagnostic equipment. |

Ready to leverage PTFE's unique properties for your medical device?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—from custom seals and liners to complex labware. Whether you are developing a new prototype or scaling up for high-volume production, our expertise ensures your medical devices meet the highest standards of safety, reliability, and performance.

Contact our experts today to discuss how our custom PTFE fabrication can enhance your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments