Expanded PTFE (ePTFE) is a uniquely versatile material whose primary advantages stem from its distinct microporous structure. It excels at creating a durable, long-lasting seal, especially on irregular surfaces, while also offering extreme chemical inertness, high-temperature resistance, and biocompatibility for sensitive applications.

While standard PTFE is known for its chemical resistance and low friction, the expansion process gives ePTFE a soft, fibrous, and porous nature. This unique structure is the source of its most significant advantages: unmatched conformability for sealing and unique properties for advanced applications like medical implants and high-performance filters.

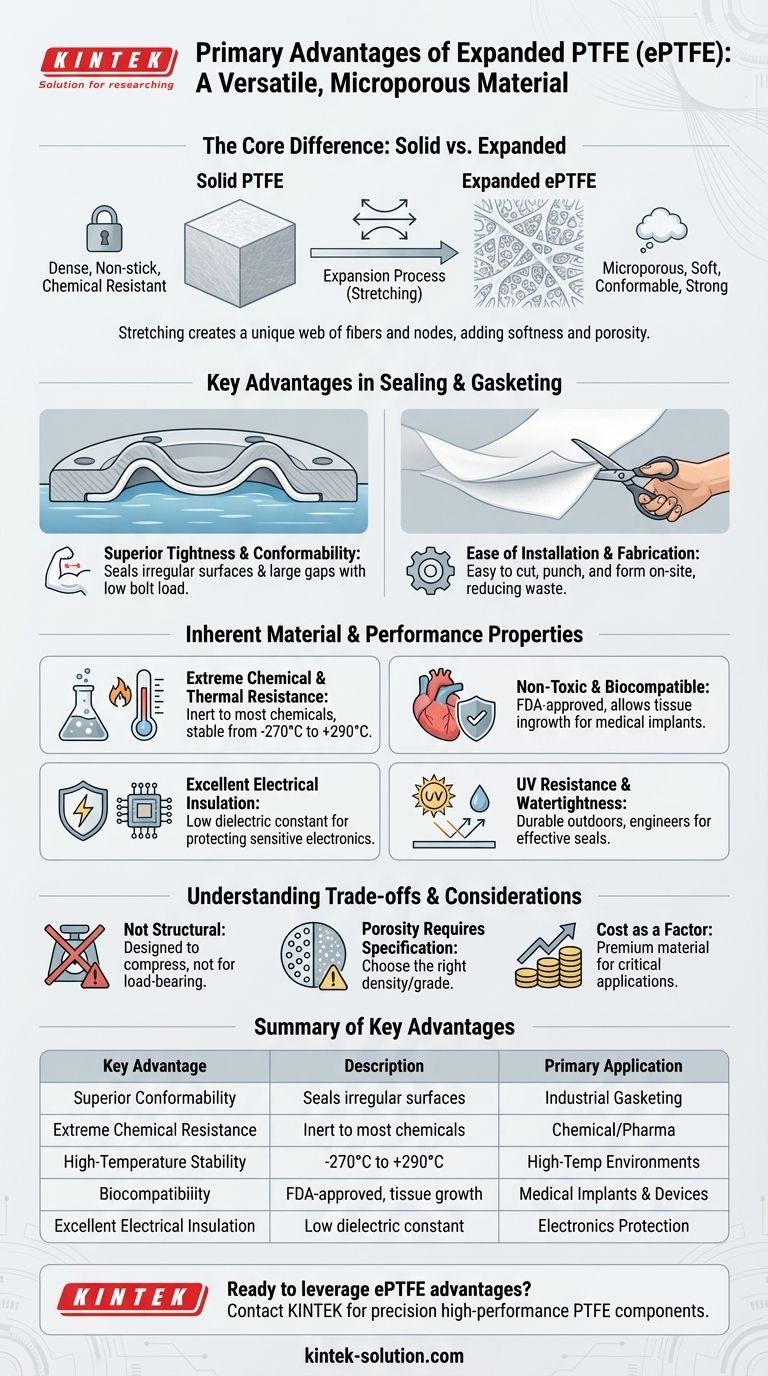

The Core Difference: Solid PTFE vs. Expanded ePTFE

To understand the advantages of ePTFE, it is essential to first understand how it differs from the material it is derived from, standard Polytetrafluoroethylene (PTFE).

What is Standard PTFE?

Standard PTFE is a fluoropolymer well-known for its remarkable properties. It is famously non-stick, highly resistant to nearly all chemicals, and stable across a wide range of temperatures. It is a dense, solid material.

The Expansion Process

Expanded PTFE (ePTFE) is created by rapidly stretching standard PTFE under specific conditions. This process pulls the material apart, creating a web-like structure of tiny fibers and nodes. The result is a material that is both strong and incredibly soft.

The Impact of the Microporous Structure

This microporous structure is the key to ePTFE's unique benefits. It retains the chemical and thermal resistance of PTFE but adds softness, conformability, and porosity. The level of porosity—and thus the material's density—can be controlled during manufacturing for different applications.

Key Advantages in Sealing and Gasketing

The most common application for ePTFE is in industrial gasketing, where its physical properties provide distinct advantages over traditional, rigid gasket materials.

Superior Tightness and Conformability

The soft, fibrous nature of ePTFE allows it to conform perfectly to surface imperfections. When compressed between two flanges, it flows into scratches, pits, and warps, creating an extremely tight and reliable seal with low bolt load.

Ideal for Wide or Irregular Flange Gaps

Rigid gaskets can fail on older, damaged, or warped flanges. ePTFE's ability to compress and conform makes it the ideal solution for creating a seal in these challenging, real-world industrial situations.

Ease of Installation and Fabrication

ePTFE is often supplied as a flexible cord or sheet. It is exceptionally easy to cut, punch, and form into custom shapes on-site, reducing waste and eliminating the need for large inventories of pre-cut gaskets.

Inherent Material and Performance Properties

ePTFE inherits the best characteristics of PTFE while adding new capabilities due to its expanded form.

Extreme Chemical and Thermal Resistance

Like standard PTFE, ePTFE is chemically inert to almost all industrial chemicals. It also maintains its integrity across a vast temperature range, with sources citing stability from -270°C up to +290°C (-454°F to +554°F).

Non-Toxic and Biocompatible

ePTFE is non-toxic, non-allergenic, and FDA-approved for food contact. Its porous structure is also highly biocompatible, allowing human tissue to grow into it. This makes it a premier material for medical implants like surgical sutures, heart patches, and artificial blood vessels.

Excellent Electrical Insulation

With a very low dielectric constant, ePTFE is an excellent electrical insulator. This property, combined with its thermal and chemical resistance, makes it valuable for protecting sensitive electronic components in harsh environments.

UV Resistance and Watertightness

The material is highly resistant to UV radiation, making it suitable for outdoor applications. While porous, it can be engineered to be completely watertight at low pressures, serving as an effective environmental seal.

Understanding the Trade-offs and Considerations

While powerful, ePTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Not a Structural Material

The softness that makes ePTFE an excellent gasket material means it is not suitable for load-bearing or structural applications. It is designed to compress and seal, not to provide rigidity.

Porosity Requires Specification

The density and porosity of ePTFE are critical variables. A high-density variant is needed for a watertight seal, whereas a low-density, more porous version might be chosen for a breathable filter or medical implant. You must select the right grade for your goal.

Cost as a Factor

As a high-performance fluoropolymer, ePTFE is a premium material. Its cost is typically higher than that of common rubber or fiber gaskets, making it best suited for critical applications where performance and reliability justify the investment.

Making the Right Choice for Your Application

Use these guidelines to determine if ePTFE is the correct choice for your project.

- If your primary focus is sealing damaged or irregular industrial flanges: ePTFE's exceptional conformability provides a reliable seal where more rigid gaskets would fail.

- If you are developing a medical device or implant: Its biocompatibility and microporous structure, which allows for tissue ingrowth, make it a premier choice.

- If you require high-purity, chemically inert components for food or pharma: ePTFE is FDA-approved and will not leach or contaminate your process.

- If you need a high-performance electrical insulator in a harsh environment: Its low dielectric constant combined with extreme durability offers superior protection.

By understanding its unique fibrous structure, you can leverage ePTFE to solve complex engineering challenges that other materials simply cannot address.

Summary Table:

| Key Advantage | Description | Primary Application |

|---|---|---|

| Superior Conformability | Soft, fibrous structure seals irregular surfaces effectively. | Industrial Gasketing |

| Extreme Chemical Resistance | Inert to almost all industrial chemicals. | Chemical Processing, Pharma |

| High-Temperature Stability | Performs from -270°C to +290°C. | High-Temp Environments |

| Biocompatibility | FDA-approved; allows tissue ingrowth. | Medical Implants & Devices |

| Excellent Electrical Insulation | Low dielectric constant for sensitive electronics. | Electronics Protection |

Ready to leverage the unique advantages of expanded PTFE for your application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom ePTFE seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get the right material solution—from prototypes to high-volume orders.

We understand that each application has unique demands. Our team will work with you to select or fabricate the ideal ePTFE component that delivers reliability, durability, and peak performance.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can solve your most challenging sealing and performance needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes PTFE a popular choice for sealing applications? Discover Its Superior Chemical & Temperature Resistance

- How does a Stretched PTFE Lip Rotary Shaft Seal work? A Low-Friction, Springless Sealing Solution

- Why is PTFE used in anti-corrosion applications? Unmatched Chemical Resistance for Harsh Environments

- Why is chemical resistance important for impeller materials? Ensure Pump Reliability and Purity

- What microstructure does expanded PTFE sheet have? Unlock Superior Sealing & Insulation

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What support and warranty options are available for custom Teflon parts? Secure Your Investment with Full Manufacturer Backing

- What role do Teflon PTFE sheets play in sewing projects? Achieve Flawless, Professional Results