In short, chemical resistance is critical for an impeller material to prevent it from being corroded, dissolved, or otherwise degraded by the fluid it is pumping. Without this property, the impeller will physically break down, leading to pump failure, process contamination, and potential safety hazards.

The choice of an impeller material is not just about mechanical strength; it's about chemical survival. Selecting a material that is incompatible with the fluid being pumped is a direct path to premature failure, costly downtime, and compromised product purity.

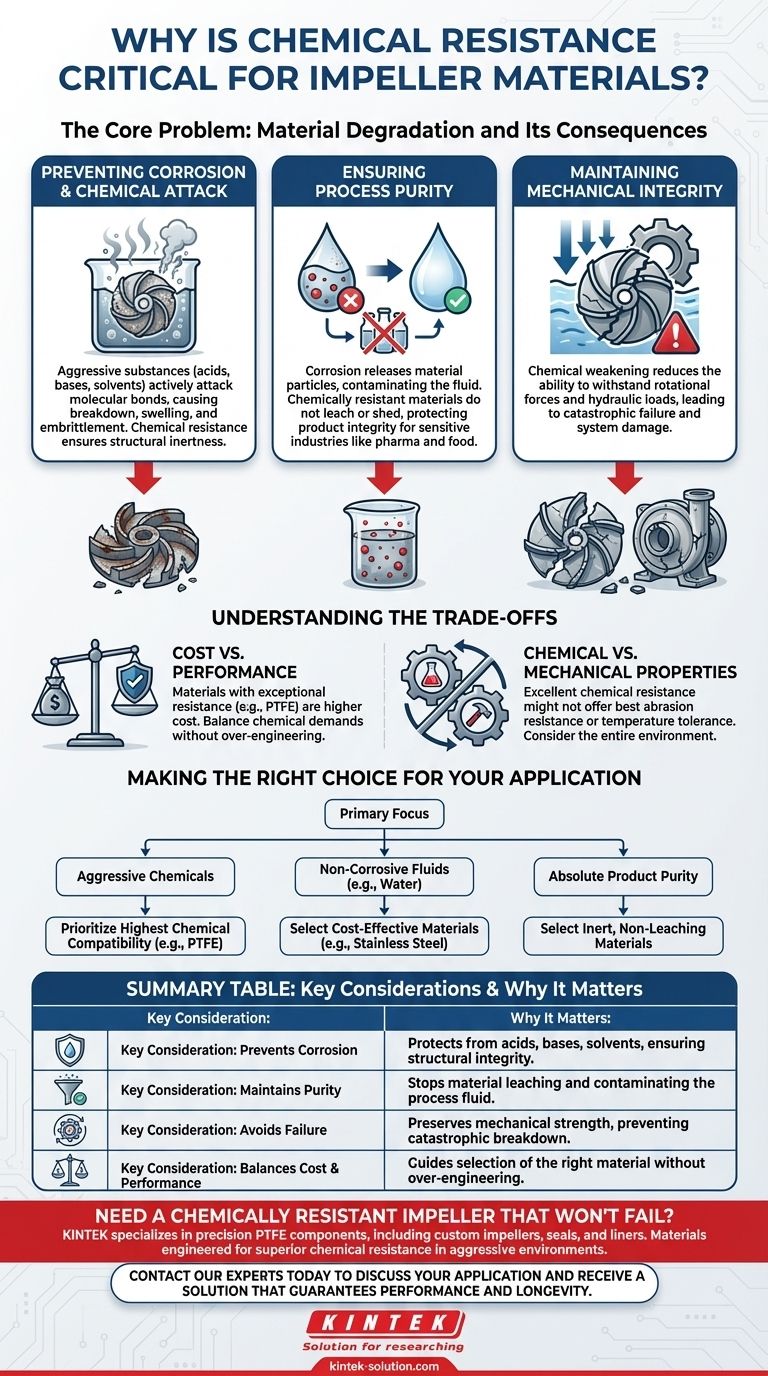

The Core Problem: Material Degradation and Its Consequences

An impeller operates under constant mechanical stress while being fully submerged in the process fluid. If the material is not chemically compatible with that fluid, a rapid breakdown is inevitable.

Preventing Corrosion and Chemical Attack

Aggressive substances like acids, bases, and organic solvents can actively attack and break down the molecular bonds of a material. This isn't just about simple rusting; it can manifest as swelling, embrittlement, or the material literally dissolving into the fluid.

Chemical resistance ensures the impeller remains structurally inert and unaffected by its environment, preserving its shape and strength.

Ensuring Process Purity

When an impeller corrodes or degrades, particles of its material break off and contaminate the fluid being pumped. In industries like pharmaceuticals, food and beverage, or high-purity electronics manufacturing, this contamination can ruin entire batches of product.

A chemically resistant material does not leach or shed particles, thereby protecting the integrity of the process fluid.

Maintaining Mechanical Integrity

The chemical integrity of a material is directly linked to its mechanical strength. As a material is weakened by chemical attack, it loses its ability to withstand the rotational forces and hydraulic loads required for pumping.

This leads to catastrophic failure, where the impeller can fracture or completely disintegrate during operation, causing severe damage to the entire pump system.

Understanding the Trade-offs

While maximum chemical resistance sounds ideal, it is part of a larger set of engineering considerations. Choosing the right material involves balancing competing factors.

Cost vs. Performance

Materials with exceptional chemical resistance, such as Polytetrafluoroethylene (PTFE), are often more expensive than standard plastics or metals. The goal is to select a material that meets the chemical demands without being excessively over-engineered for the application.

Chemical vs. Mechanical Properties

A material that excels in chemical resistance might not have the best properties for abrasion resistance or temperature tolerance. For example, a PTFE impeller is ideal for pumping pure acid but would wear quickly if the fluid contained abrasive solids.

The entire operational environment—chemical composition, temperature, and physical solids—must be considered together.

Making the Right Choice for Your Application

The selection process must begin with a clear understanding of the fluid being pumped and the primary operational goal.

- If your primary focus is handling aggressive chemicals: Prioritize materials with the highest chemical compatibility for your specific fluid, such as PTFE, even if it comes at a higher initial cost.

- If your primary focus is pumping non-corrosive fluids (like water): A wide range of less expensive materials, including stainless steel or various plastics, will be perfectly suitable and more cost-effective.

- If your primary focus is ensuring absolute product purity: Select an inert material known for its non-leaching properties, where high chemical resistance is a fundamental requirement to prevent contamination.

Ultimately, matching the impeller's material to its chemical environment is the most critical factor in ensuring a pump's reliability and longevity.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Prevents Corrosion | Protects the impeller from acids, bases, and solvents, ensuring structural integrity. |

| Maintains Purity | Stops material particles from leaching into and contaminating the process fluid. |

| Avoids Failure | Preserves mechanical strength under stress, preventing catastrophic breakdown. |

| Balances Cost & Performance | Guides selection of the right material (e.g., PTFE for chemicals) without over-engineering. |

Need a chemically resistant impeller that won't fail?

KINTEK specializes in manufacturing precision PTFE components, including custom impellers, seals, and liners. Our materials are engineered for superior chemical resistance, ensuring your pump systems operate reliably in the most aggressive environments—from semiconductor manufacturing to pharmaceutical processing.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific fluid and purity requirements.

Contact our experts today to discuss your application and receive a solution that guarantees performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials