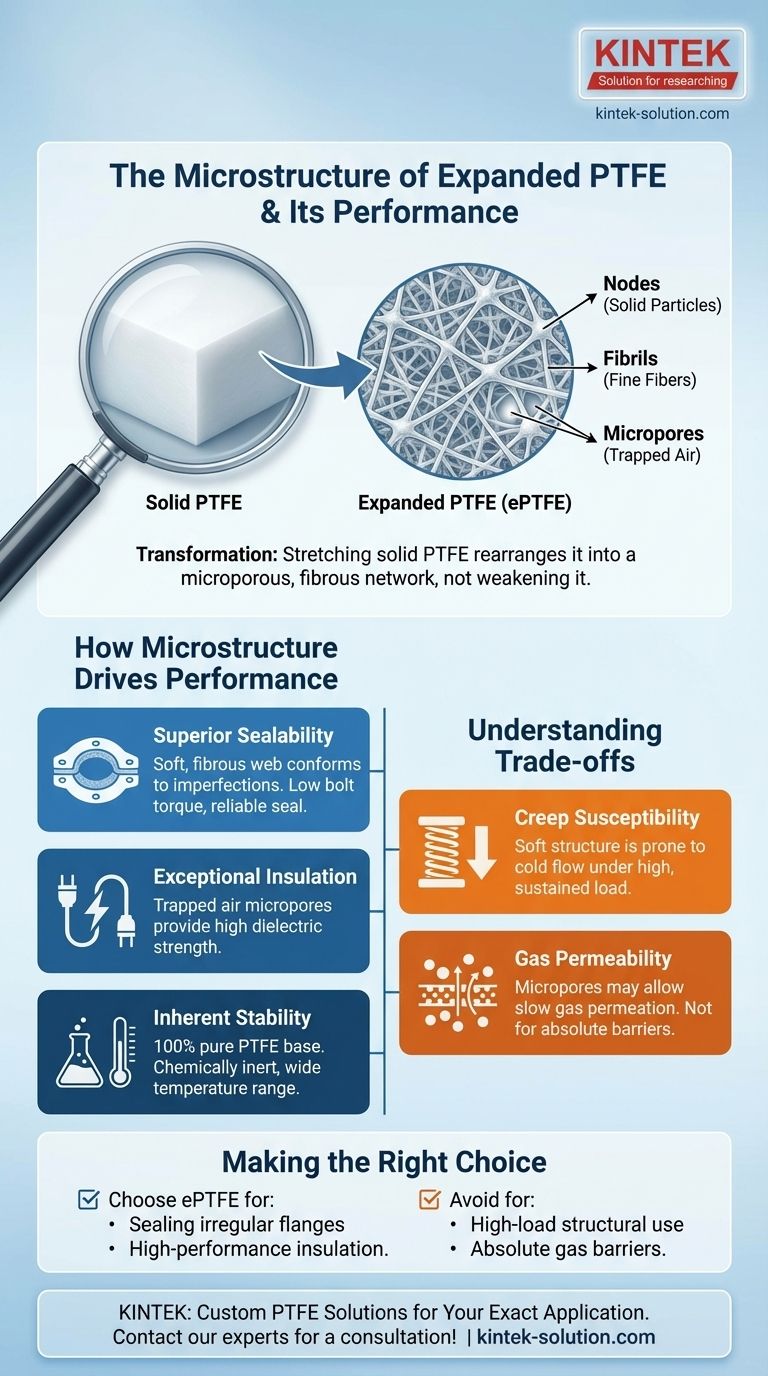

At its core, expanded PTFE (ePTFE) sheet has a unique microstructure defined by a web of interconnected nodes and fine fibers, known as fibrils. This porous, highly fibrillated structure is created by mechanically stretching solid PTFE, which transforms the material and is the direct source of its most valuable performance characteristics, such as exceptional sealability and insulation.

The key insight is that the process of expanding PTFE doesn't weaken it, but rather rearranges it into a microporous, fibrous network. This structure is precisely what allows it to compress and conform for superior sealing while trapping air for excellent insulation.

The Anatomy of an Expanded PTFE Sheet

To understand ePTFE's performance, you must first visualize its internal architecture. It is fundamentally different from solid, or virgin, PTFE.

From Solid Block to Fibrous Web

The manufacturing process begins with a special grade of fine PTFE powder that is extruded into a solid form. This solid is then rapidly stretched under controlled, high-temperature conditions.

This stretching process pulls the material's molecular structure apart, creating a network of solid PTFE particles (nodes) connected by extremely thin, strong fibers (fibrils).

Nodes and Fibrils: The Building Blocks

The resulting material is not a uniform solid. It is a microscopic web that is mostly empty space.

The nodes are remnants of the original, unstretched PTFE material. The fibrils are the highly oriented strands that link these nodes together, giving the material its strength and flexibility.

The Critical Role of Porosity

The space between the fibrils creates a microporous structure. This porosity is not a defect; it is a critical design feature. These tiny, trapped pockets of air are what make ePTFE an outstanding thermal and electrical insulator.

How Microstructure Drives Performance

Each key performance attribute of ePTFE can be traced directly back to this unique node-and-fibril structure.

Superior Sealability and Conformability

When used as a gasket, the soft, fibrous web of ePTFE easily compresses under load. The fibrils deform and flow into the microscopic imperfections of a flange surface, creating an exceptionally tight and reliable seal with low bolt torque.

This is a significant advantage over hard, rigid gaskets that require much higher clamping forces and perfectly flat surfaces to prevent leaks.

Exceptional Dielectric Strength

Air is an excellent electrical insulator. The microporous structure of ePTFE traps a high volume of air within its fibrous network.

This composition makes ePTFE a superior insulator, or dielectric material, ideal for wrapping high-performance cables and isolating sensitive electronic components.

Inherent Chemical and Thermal Stability

Because ePTFE is made from 100% pure polytetrafluoroethylene, it retains all the remarkable properties of the base polymer. It remains chemically inert to almost all industrial chemicals and maintains its integrity across a very wide temperature range.

Understanding the Trade-offs

While powerful, the ePTFE microstructure is not universally ideal. Its unique properties introduce specific limitations that must be considered.

Creep Resistance vs. Compressibility

The same softness that makes ePTFE an excellent sealant also makes it more susceptible to creep, or cold flow, under high, sustained mechanical loads. The fibrous structure can slowly continue to compress over time.

For applications requiring high load-bearing capacity without deformation, a solid or filled-PTFE material may be more appropriate.

Permeability in Specific Cases

The porous structure, while excellent for insulation, means the material is not completely impermeable. While it will effectively block liquids, very small gas molecules may be able to slowly permeate through the microscopic pores over time.

This is a critical consideration for high-vacuum systems or the long-term sealing of specific gases where zero permeability is required.

Making the Right Choice for Your Application

Selecting the right material requires aligning its microstructure with your primary engineering goal.

- If your primary focus is sealing irregular or fragile flanges: ePTFE's soft, conformable fibrous structure is the ideal choice for creating a tight seal with low stress.

- If your primary focus is high-performance electrical or thermal insulation: The air-trapping porosity of ePTFE makes it a superior dielectric and insulating material.

- If your primary focus is a high-load structural component: The tendency of ePTFE to creep makes solid PTFE or a reinforced composite a more suitable choice.

Understanding that ePTFE's performance comes from its structure—not just its chemistry—is the key to deploying it effectively.

Summary Table:

| Performance Characteristic | How ePTFE Microstructure Enables It |

|---|---|

| Superior Sealability | Soft, fibrous web compresses and conforms to surface imperfections with low bolt torque. |

| Exceptional Insulation | Microporous structure traps air, providing excellent dielectric and thermal properties. |

| Chemical/Thermal Stability | Made from 100% PTFE, retaining the base polymer's inertness and wide temperature range. |

| Trade-off: Creep | Fibrous structure is susceptible to cold flow under high, sustained loads. |

| Trade-off: Permeability | Microporous nature may allow slow gas permeation, unsuitable for absolute gas barriers. |

Need a high-performance PTFE component tailored to your exact application?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom ePTFE sheets, seals, liners, and labware. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact material properties and performance you need for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Let us help you solve your sealing or insulation challenge. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the six main factors affecting CNC machining of PTFE parts? Master Precision Machining for High-Performance Polymers

- Why are PTFE lined valves considered a reliable choice for industrial processes? Achieve Unmatched Chemical Resistance & Longevity

- What are the benefits of Teflon's non-stick properties in industrial settings? Boost Uptime & Cut Costs

- What are the main advantages of expanded PTFE gaskets? Superior Sealing Reliability vs. Pure PTFE

- How should PTFE gaskets be stored to maintain their quality? Ensure Long-Term Sealing Reliability

- How do PTFE and NBR oil seals compare in terms of temperature resistance? Choose the Right Seal for Extreme Heat

- What are the properties of Teflon PFA encapsulated o-rings? Achieve Superior Sealing in Extreme Environments