At their core, PTFE flat washers are high-performance components defined by three primary characteristics: an extremely low coefficient of friction, exceptional resistance to virtually all chemicals, and the ability to operate across a vast range of temperatures. These properties make them the definitive choice for sealing, spacing, and insulation in demanding industrial environments where conventional materials would fail.

Choosing a PTFE flat washer is not a decision about mechanical strength, but about environmental resilience. Its value lies in its chemical inertness, temperature stability, and electrical insulation, making it a problem-solver for applications involving corrosive substances, extreme temperatures, or electrical isolation.

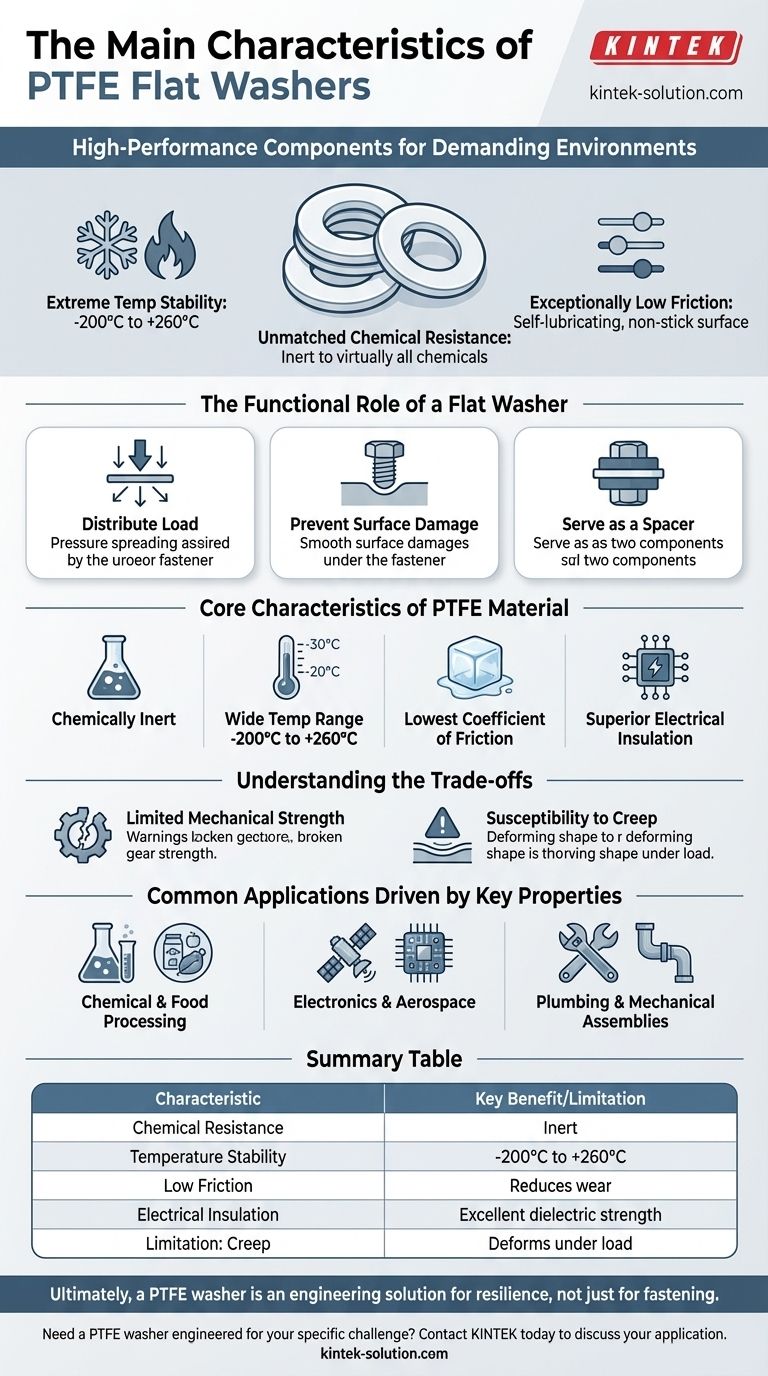

The Functional Role of a Flat Washer

Before examining the material itself, it's crucial to understand the fundamental purpose of any flat washer.

Distributing Load

A washer's primary job is to distribute the pressure of a nut or bolt head over a wider surface area. This prevents the fastener from damaging the material it's being secured to.

Preventing Surface Damage

By creating a smooth, stable surface for the fastener to turn against, a washer protects delicate or finished surfaces from being marred during tightening.

Serving as a Spacer

In many assemblies, washers are used to create a specific gap or to align components correctly, acting as a simple and precise spacer.

Core Characteristics of PTFE Material

The unique properties of Polytetrafluoroethylene (PTFE) are what distinguish these washers from standard metal or plastic alternatives.

Unmatched Chemical Resistance

PTFE is chemically inert to nearly all industrial chemicals, acids, and bases. This makes it an essential component in chemical processing, pharmaceutical, and food-grade applications where corrosion or contamination is unacceptable.

Extreme Temperature Stability

These washers perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This allows them to be used in everything from cryogenic systems to high-temperature industrial equipment.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating, non-stick surface is ideal for dynamic assemblies where it can reduce wear and prevent seizing.

Superior Electrical Insulation

As an excellent electrical insulator with high dielectric strength, PTFE is widely used in electronics. It effectively isolates components, preventing short circuits, especially in high-temperature or high-frequency applications.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every problem. Understanding its limitations is critical for proper application.

Limited Mechanical Strength

PTFE is a relatively soft material. It does not possess the high tensile or compressive strength of metals. For high-load structural applications, a metallic washer is often required.

Susceptibility to Creep Under Load

The most significant drawback of PTFE is its tendency to "creep," or cold flow. When placed under a constant compressive load, the material will slowly deform over time, which can lead to a loss of bolt tension and joint integrity.

Common Applications Driven by Key Properties

The choice to use a PTFE washer is almost always driven by a specific environmental challenge.

In Chemical and Food Processing

Here, its chemical inertness and non-contaminating nature are paramount. The washers will not degrade when exposed to aggressive cleaning agents or process chemicals, ensuring purity.

In Electronics and Aerospace

The combination of high-temperature resistance and electrical insulation makes PTFE ideal for mounting components on circuit boards or isolating fasteners in sensitive aerospace assemblies.

In Plumbing and Mechanical Assemblies

In applications with delicate surfaces or the need for a low-friction seal, PTFE washers prevent galling and provide a reliable, corrosion-proof seal.

Making the Right Choice for Your Application

To determine if a PTFE washer is the correct component, evaluate your primary engineering goal.

- If your primary focus is preventing corrosion or contamination: PTFE's chemical inertness is its most valuable asset, making it ideal for food, medical, and chemical processing.

- If your primary focus is electrical isolation: PTFE's high dielectric strength provides a reliable insulating barrier in electronics and high-voltage equipment.

- If your primary focus is reducing friction in a dynamic assembly: The self-lubricating, non-stick surface of PTFE reduces wear and ensures smooth movement without external lubricants.

- If your primary focus is high structural load and clamp force retention: You should evaluate a harder material, as PTFE's tendency to creep can compromise the joint's integrity over time.

Ultimately, a PTFE washer is an engineering solution for resilience, not just for fastening.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| Chemical Resistance | Inert to virtually all chemicals, acids, and bases |

| Temperature Stability | Performs from -200°C to +260°C (-328°F to +500°F) |

| Low Friction | Self-lubricating, non-stick surface reduces wear |

| Electrical Insulation | Excellent dielectric strength for isolating components |

| Limitation: Creep | Can deform under constant load, affecting clamp force |

Need a PTFE washer engineered for your specific challenge?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that delivers unmatched chemical resistance, temperature stability, and reliability.

Contact KINTEK today to discuss your application and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments