The primary advantages of using PTFE seals are their exceptional resilience in extreme operating conditions. They exhibit superior chemical inertness against aggressive media, maintain integrity across a vast temperature range, and possess an inherently low coefficient of friction that reduces wear and the need for lubrication. This unique combination of properties makes them a premier choice for demanding industrial applications.

PTFE seals are not just components; they are a strategic solution for high-performance systems where standard elastomer seals would quickly fail. Their core value is providing reliable, long-term sealing in chemically aggressive, high-temperature, or high-speed environments, ultimately reducing maintenance and total cost of ownership.

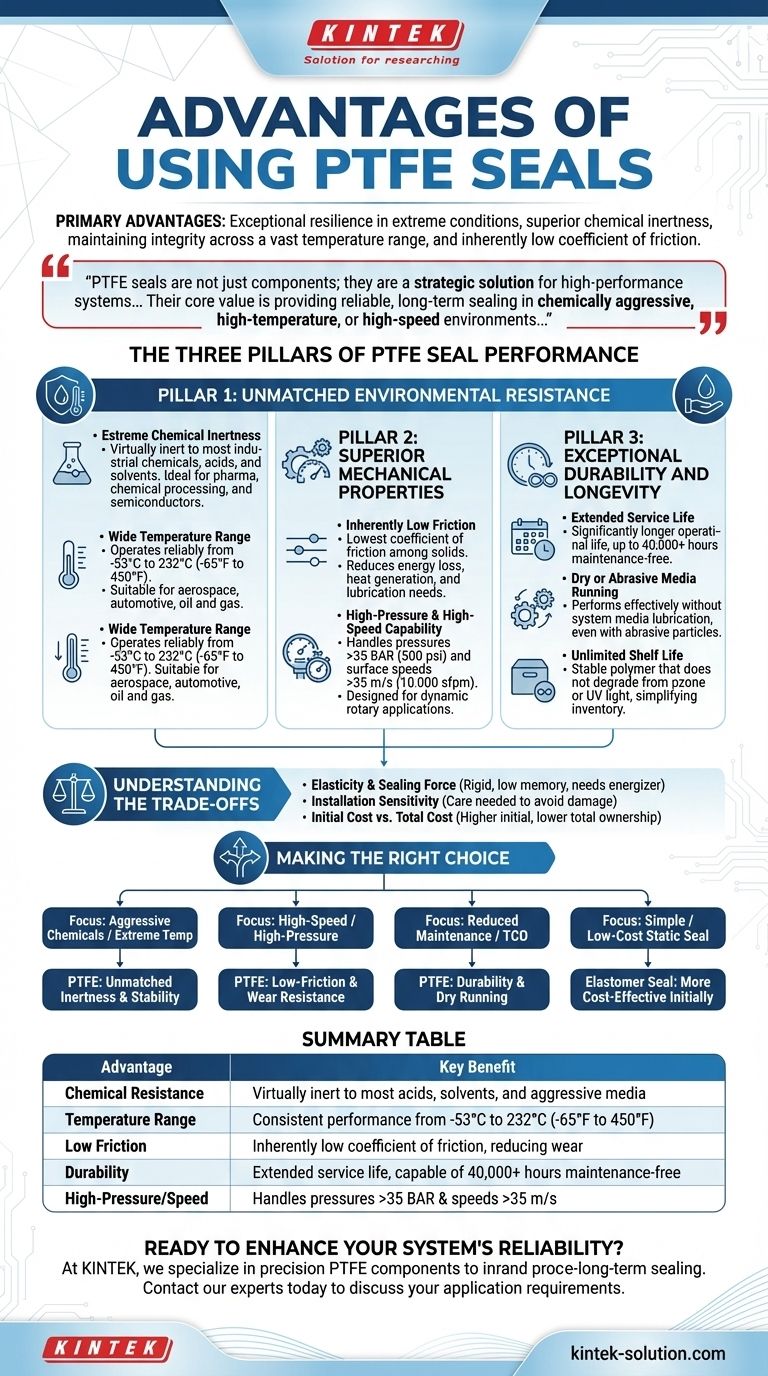

The Three Pillars of PTFE Seal Performance

To understand if a PTFE seal is right for your application, it's best to evaluate its advantages across three core areas: environmental resistance, mechanical properties, and long-term durability.

Pillar 1: Unmatched Environmental Resistance

The material composition of Polytetrafluoroethylene (PTFE) gives it a powerful defense against harsh environments.

Extreme Chemical Inertness PTFE is virtually inert to most industrial chemicals, acids, and solvents. This makes it an essential material in industries like pharmaceuticals, chemical processing, and semiconductor manufacturing, where seal integrity cannot be compromised by aggressive fluids.

Wide Temperature Range These seals perform reliably in both cryogenic and high-heat conditions. They can operate consistently in temperatures ranging from -53°C to 232°C (-65°F to 450°F), making them ideal for aerospace, automotive, and oil and gas applications.

Pillar 2: Superior Mechanical Properties

PTFE seals are engineered for dynamic applications where friction, pressure, and speed are critical factors.

Inherently Low Friction PTFE has one of the lowest coefficients of friction of any solid material. This natural lubricity reduces energy loss, minimizes heat generation, and allows systems to run more efficiently without external lubrication.

High-Pressure and High-Speed Capability Standard PTFE seals can handle pressures in excess of 35 BAR (500 psi). They are also designed for high-speed rotary applications, capable of withstanding surface speeds of over 35 m/s (10,000 sfpm) where traditional seals would degrade.

Pillar 3: Exceptional Durability and Longevity

The ultimate goal of a high-performance seal is to reduce downtime and maintenance, and PTFE excels here.

Extended Service Life Due to their high wear resistance, PTFE seals have a significantly longer operational life than many alternatives, with some applications reporting over 40,000 hours of maintenance-free service.

Ability to Run in Dry or Abrasive Media Because they don't rely on system media for lubrication, PTFE seals can perform effectively in dry-running conditions or in the presence of abrasive particles that would destroy other seal types.

Unlimited Shelf Life Unlike many elastomers that can degrade over time from exposure to ozone or UV light, PTFE is a stable polymer with an unlimited shelf life, simplifying inventory management.

Understanding the Trade-offs

While incredibly capable, PTFE seals are not a universal solution. An objective assessment requires understanding their limitations.

Elasticity and Sealing Force

PTFE is a relatively rigid plastic, not a flexible rubber. It has poor elastic memory, meaning it won't spring back into shape like an elastomer. For this reason, many PTFE seals incorporate an energizer (like a metal spring) to provide the constant force needed to maintain a tight seal, especially in low-pressure situations.

Installation Sensitivity

The rigidity of PTFE can make installation more challenging than for a simple O-ring. Care must be taken to avoid scratching or gouging the seal lip, which could create a leak path. Some designs incorporate elastomer coatings to ease installation.

Initial Cost vs. Total Cost

The initial procurement cost of a custom-engineered PTFE seal is typically higher than a standard elastomer seal. The financial advantage comes from a lower total cost of ownership, driven by reduced maintenance, less downtime, and longer service intervals.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its strengths to your primary operational goal.

- If your primary focus is aggressive chemicals or extreme temperatures: PTFE is often the only viable choice due to its unmatched chemical inertness and thermal stability.

- If your primary focus is high-speed or high-pressure rotary applications: The low-friction and wear-resistant properties of PTFE deliver a superior solution for extending service life and improving efficiency.

- If your primary focus is reducing maintenance and total cost of ownership: PTFE's durability and ability to run in dry or abrasive media can significantly lower long-term operational expenses.

- If your primary focus is a simple, low-cost static seal in a mild environment: A standard elastomer seal may be a more cost-effective initial choice if the demanding conditions for PTFE are not present.

By understanding these core strengths and trade-offs, you can confidently specify PTFE seals for applications where performance and reliability are non-negotiable.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Resistance | Virtually inert to most acids, solvents, and aggressive media |

| Temperature Range | Consistent performance from -53°C to 232°C (-65°F to 450°F) |

| Low Friction | Inherently low coefficient of friction, reducing wear and energy loss |

| Durability | Extended service life, capable of over 40,000 hours maintenance-free |

| High-Pressure/Speed | Handles pressures >35 BAR and surface speeds >35 m/s |

Ready to enhance your system's reliability with high-performance PTFE seals?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution engineered for your specific demands, reducing maintenance and total cost of ownership.

Contact our experts today to discuss your application requirements and discover the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the thermal properties of PTFE that make it ideal for seals? Ensuring Reliability in Extreme Conditions

- What are the maintenance requirements for PTFE slide bearings? Ensure Long-Term, Maintenance-Free Performance

- Why are Teflon gland fillers suitable for food and beverage processing? Ensure Purity and Reliability

- How does PTFE contribute to the sealing performance of ball valves? Achieve Leak-Free, Durable Sealing

- In what types of environments are PTFE seat butterfly valves most suitable? Ideal for Corrosive, High-Purity Applications

- In which industries or applications are PTFE O-rings typically used? Solve Extreme Sealing Challenges

- What are the benefits of using Teflon sheets in heat press machines? Achieve Flawless Transfers & Protect Your Equipment

- Why are PTFE gaskets considered reliable sealing solutions? Unmatched Chemical & Thermal Stability