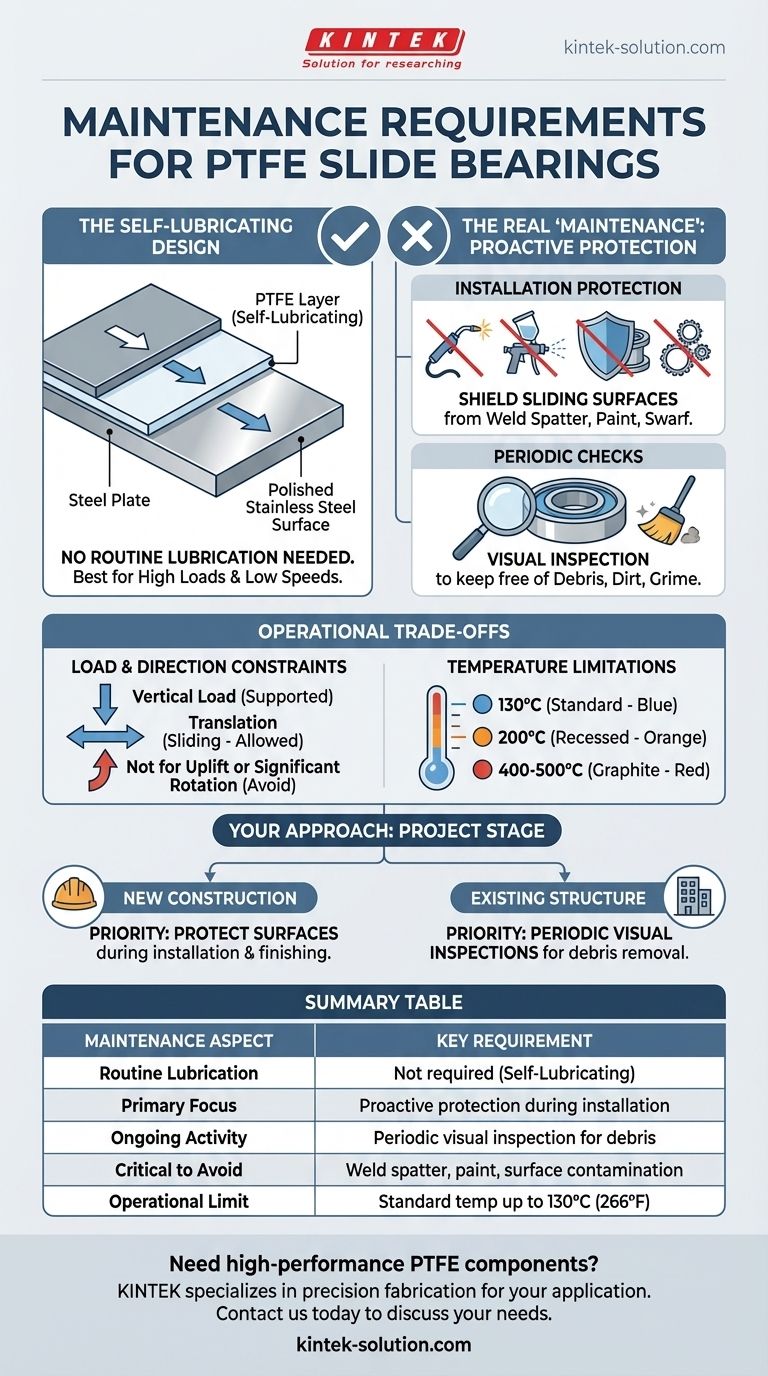

Fundamentally, PTFE slide bearings are considered maintenance-free. Their self-lubricating properties eliminate the need for regular lubrication or frequent, detailed inspections. However, their long-term performance hinges on correct installation and periodic checks to ensure the sliding surfaces remain clear of debris.

The term "maintenance-free" is more of an outcome than a guarantee. It is achieved not through ongoing intervention, but through meticulous care during installation and the prevention of contamination over the bearing's life.

How PTFE Bearings Eliminate Routine Maintenance

PTFE slide bearings are engineered to provide a durable, low-friction surface that requires no external lubrication. This capability is built into their core design.

The Self-Lubricating Mechanism

The bearing typically consists of a layer of Polytetrafluoroethylene (PTFE) on one steel plate that slides against a highly polished stainless steel plate. The extremely low coefficient of friction between these two surfaces allows for smooth movement.

This mechanism is most effective under high loads and low speeds, which are typical conditions in the structures where they are used, such as bridges and large buildings.

Key Components

A standard assembly includes two primary steel plates. One plate has a layer of PTFE bonded to it or recessed into it, while the mating plate features the polished stainless steel sliding surface.

This simple, robust construction is what allows the bearing to manage forces from thermal expansion, seismic shifts, and other structural movements without requiring lubrication.

The Real "Maintenance": Proactive Protection

While you won't be scheduling regular greasing, the long-term reliability of a PTFE bearing is determined by proactive steps taken during and after installation.

Critical Installation Practices

The method of installation must be chosen carefully. Bearings can be attached by bolting, tack-welding, full welding, or being embedded in mortar.

The most crucial factor during this phase is protecting the bearing's functional surfaces.

Shielding the Sliding Surfaces

The PTFE and stainless steel surfaces must be shielded from damage. Weld spatter, paint spray, and metal swarf from construction can permanently compromise the bearing's performance.

Any damage to the polished stainless steel or the PTFE can increase friction and prevent the smooth movement the bearing is designed to allow.

The Role of Debris

Periodic visual checks are the only recommended ongoing activity. The goal is to ensure the sliding interface is free from accumulated dirt, salt, road grime, or other debris.

Contaminants can score the surfaces or clog the interface, hindering free movement and potentially damaging the bearing over time.

Understanding Operational Trade-offs

The "maintenance-free" status of PTFE bearings is contingent on operating them within their designed limits. Exceeding these parameters can lead to premature failure.

Load and Directional Constraints

PTFE bearings are designed to support significant vertical loads while permitting translation (sliding) in longitudinal and transverse directions. They are not intended to handle uplift or significant rotational forces unless specifically designed to do so.

Temperature Limitations

The materials used dictate the operational temperature range. A standard configuration with PTFE bonded to a backing plate is typically rated for up to 130°C (266°F).

For higher heat environments, specialized designs with PTFE recessed into the plate can handle up to 200°C (392°F). For extreme heat, graphite-based bearings are used, which can withstand temperatures of 400-500°C (752-932°F).

Making the Right Choice for Your Goal

Your approach to PTFE bearings should be dictated by your role and the project's life cycle stage.

- If your primary focus is new construction: Your top priority must be protecting the bearing's sliding surfaces from all forms of contamination and damage during the entire installation and finishing process.

- If your primary focus is managing an existing structure: Implement a simple schedule for periodic visual inspections, ensuring the area around the bearing is clear of any debris that could impede movement or score the surfaces.

Ultimately, the exceptional service life of a PTFE bearing is secured by diligence at the start, not by intervention at the end.

Summary Table:

| Maintenance Aspect | Key Requirement |

|---|---|

| Routine Lubrication | Not required (self-lubricating) |

| Primary Focus | Proactive protection during installation |

| Ongoing Activity | Periodic visual inspection for debris |

| Critical to Avoid | Weld spatter, paint, and surface contamination |

| Operational Limit | Standard temperature up to 130°C (266°F) |

Need high-performance, maintenance-free PTFE components for your project?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your PTFE parts are built to last, reducing long-term maintenance and enhancing operational reliability.

Whether you need prototypes or high-volume orders, we deliver custom fabrication tailored to your exact requirements.

Contact us today to discuss how our PTFE solutions can benefit your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech