In the world of industrial sealing, few materials command the respect of Polytetrafluoroethylene (PTFE). Its reputation for reliability is not based on a single attribute, but on a rare combination of extreme chemical inertness, a vast operational temperature range, and unique mechanical properties that allow it to form a near-perfect seal even on imperfect surfaces. This versatility makes it a go-to solution for some of the most demanding applications.

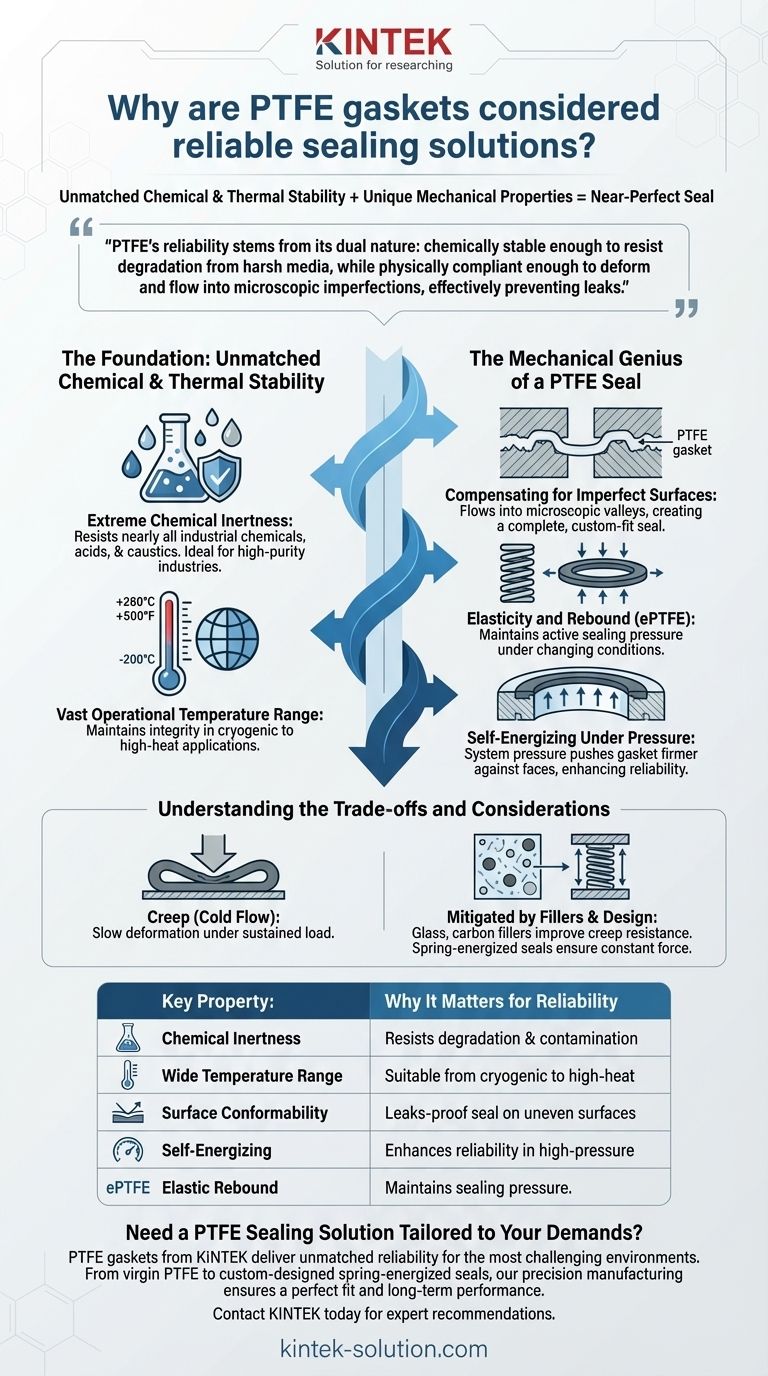

PTFE's reliability stems from its dual nature: it is chemically stable enough to resist degradation from harsh media, while being physically compliant enough to deform and flow into the microscopic imperfections of a sealing surface, effectively preventing leaks where more rigid materials would fail.

The Foundation: Unmatched Chemical and Thermal Stability

The core of PTFE's performance lies in its fundamental molecular structure. This structure grants it properties that are nearly unmatched by other polymers, forming the first layer of its reliability.

Extreme Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and caustics. This inertness means the gasket itself will not degrade, swell, or weaken when exposed to aggressive process media.

This property is also critical for high-purity industries like pharmaceuticals and food processing, as the gasket will not leach contaminants into the product stream.

A Vast Operational Temperature Range

PTFE maintains its integrity and sealing properties across an exceptionally wide temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This makes it one of the few materials suitable for both cryogenic applications and high-temperature processes, eliminating the need to source different materials for different thermal environments.

Low-Friction Surface

The famously low coefficient of friction of PTFE (one of the lowest of any solid) reduces the torque needed to tighten flanges and prevents galling or damage to sealing surfaces during installation.

The Mechanical Genius of a PTFE Seal

Beyond its chemical and thermal resilience, PTFE's reliability is cemented by its physical behavior under compression. It actively works to create and maintain a seal in ways that rigid materials cannot.

Compensating for Imperfect Surfaces

No industrial surface is perfectly flat. Flanges can have minor machining marks, scratches, or distortions. PTFE's softness and plasticity are key advantages here.

Under compression, the material flows into these microscopic valleys and cracks, creating a complete, custom-fit seal that perfectly mirrors the topography of the hardware. This ability to compensate for imperfections is a primary reason it prevents leaks so effectively.

Elasticity and Rebound

A good gasket must not only compress but also push back against the sealing surfaces. This "rebound" is what maintains the sealing force over time.

Expanded PTFE (ePTFE), a specialized form of the material, possesses excellent elasticity. It adapts to the shape of the sealing gap and maintains this active pressure even under changing temperature and pressure conditions.

Self-Energizing Under Pressure

Many PTFE gasket designs exhibit a self-energizing characteristic. As the pressure of the fluid or gas inside the system increases, that pressure acts upon the gasket.

This force pushes the gasket more firmly against the sealing faces, effectively increasing the sealing force precisely when it is needed most. This dynamic response adds a significant layer of safety and reliability in high-pressure applications.

Understanding the Trade-offs and Considerations

While remarkably capable, PTFE is not without its limitations. Understanding these trade-offs is crucial for proper material specification and joint design.

The Issue of Creep (Cold Flow)

Under a sustained compressive load, especially at elevated temperatures, standard PTFE can be susceptible to creep, also known as cold flow. This is a slow, permanent deformation that can lead to a loss of sealing stress and potential leaks over time.

Lower Mechanical Strength

Compared to metallic or highly filled gaskets, virgin PTFE has lower compressive strength. Over-tightening can easily crush the material or cause it to extrude out of the flange, compromising the seal.

How Fillers and Design Mitigate Weaknesses

These trade-offs are well understood and are often engineered out of the final product. Fillers like glass, carbon, or graphite are added to the PTFE matrix to dramatically improve creep resistance and compressive strength.

Furthermore, specialized designs like spring-energized seals use a metal spring to provide a constant resilient force, ensuring the PTFE jacket always remains in contact with the sealing surface, even if some material relaxation occurs.

Making the Right Choice for Your Application

Selecting the correct PTFE variant is about matching its specific strengths to your primary challenge.

- If your primary focus is chemical purity and resistance: Virgin PTFE is the default choice due to its unparalleled inertness, ensuring no product contamination.

- If you are sealing in extreme temperatures (cryogenic or high heat): PTFE's wide and stable operating range makes it a top contender for both ends of the spectrum.

- If your flange surfaces are imperfect or subject to vibration: The exceptional conformability of a soft virgin or expanded PTFE (ePTFE) gasket is a key advantage.

- If you are managing high pressure and are concerned about creep: Specify a filled PTFE (glass, carbon) or an engineered solution like an ePTFE or spring-energized gasket.

By understanding these core principles, you can confidently specify a PTFE sealing solution that ensures both operational safety and long-term reliability.

Summary Table:

| Key Property | Why It Matters for Reliability |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and caustics without degrading or contaminating the process. |

| Wide Temperature Range | Maintains sealing integrity from -200°C to +260°C, suitable for cryogenic to high-heat applications. |

| Surface Conformability | Flows into microscopic imperfections on flanges, creating a custom, leak-proof seal even on uneven surfaces. |

| Self-Energizing Under Pressure | System pressure increases sealing force, enhancing reliability in high-pressure environments. |

| Elastic Rebound (ePTFE) | Maintains active sealing pressure under temperature fluctuations and vibrations. |

Need a PTFE Sealing Solution Tailored to Your Demands?

PTFE gaskets from KINTEK deliver unmatched reliability for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors. Whether you require virgin PTFE for ultimate chemical purity, filled PTFE for enhanced creep resistance, or custom-designed seals for high-pressure applications, our precision manufacturing ensures a perfect fit and long-term performance.

We specialize in custom fabrication—from rapid prototypes to high-volume production—ensuring your sealing components meet exact specifications.

Contact KINTEK today to discuss your project and receive a expert recommendation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries are spiral PTFE backup rings ideal for? Achieve Superior Sealing in Extreme Conditions

- What makes PTFE an ideal sealing material overall? Superior Performance in Extreme Conditions

- What are the benefits of glass-filled PTFE sheet? Achieve Superior Strength and Wear Resistance

- What are some common defects of PTFE gaskets and how can they be managed? Mitigate Creep & Cold Flow for Reliable Seals

- How do PTFE coatings benefit industrial manufacturing? Enhance Equipment Life & Efficiency

- How does chemical resistance benefit PTFE Teflon washers? Ensure Leak-Free Seals in Harsh Environments

- What are PTFE gaskets and what are their key properties? Solve Sealing Challenges in Extreme Conditions

- Why are PTFE Liners preferred for catheter systems? Superior Lubricity, Biocompatibility & Safety