At its core, a Polytetrafluoroethylene (PTFE) heat press sheet offers three primary advantages: an exceptional non-stick surface, high heat resistance, and durable reusability. These properties combine to protect both your project and your equipment, ensuring consistent, professional-quality results while being highly cost-effective over time.

A PTFE sheet is best understood not as an accessory, but as an essential protective barrier. Its purpose is to eliminate common points of failure in the heat transfer process, such as scorching, staining, and uneven heat application.

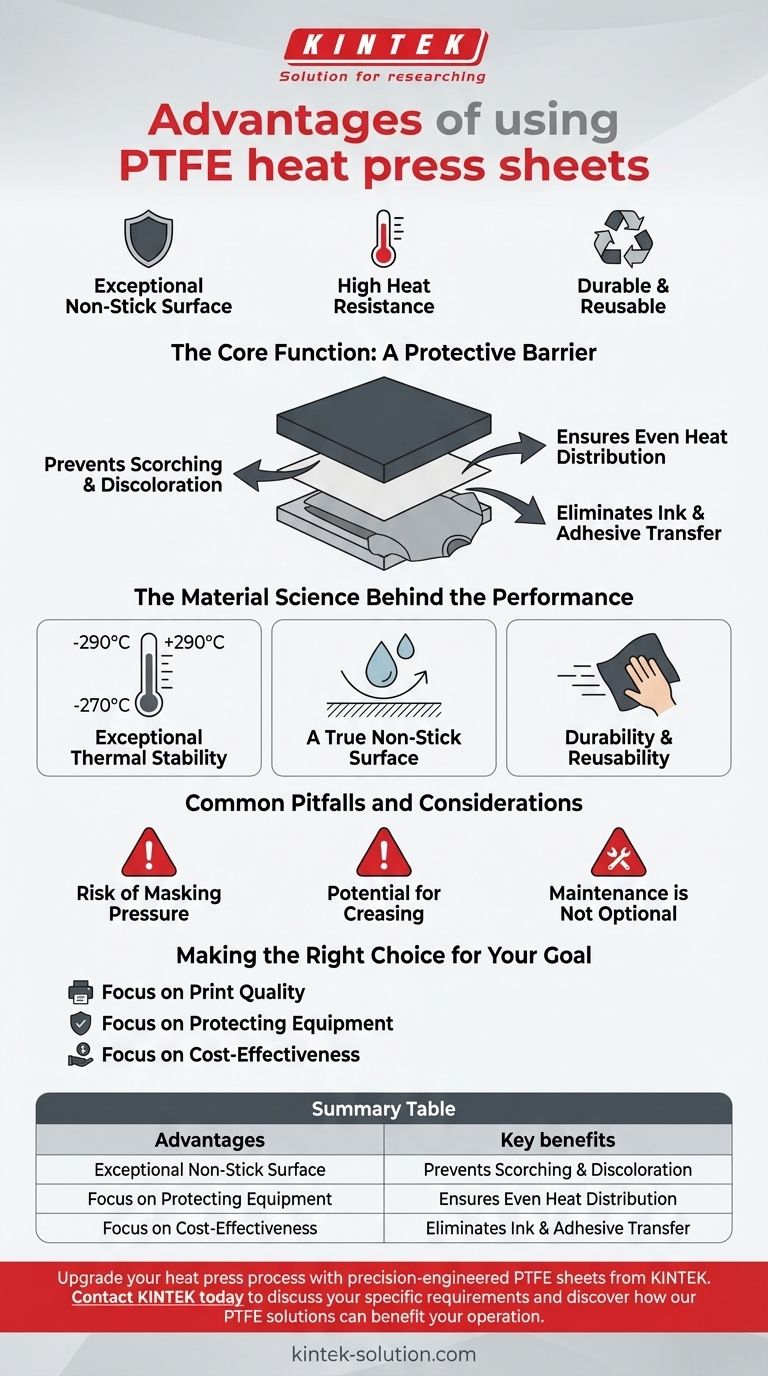

The Core Function: A Protective Barrier

The primary role of a PTFE sheet is to sit between your heat press platen and your garment or substrate. This simple act solves several critical problems that can otherwise ruin a project.

Preventing Scorching and Discoloration

A PTFE sheet acts as a buffer, diffusing the direct, intense heat from the platen. This is crucial for protecting delicate and heat-sensitive fabrics like polyester from burning, scorching, or yellowing under high temperatures.

Ensuring Even Heat Distribution

The sheet helps to smooth out any minor temperature inconsistencies or "hot spots" on the surface of your heat platen. This ensures the heat is applied evenly across the entire transfer, leading to a more consistent and professional finish.

Eliminating Ink and Adhesive Transfer

Its non-stick surface is indispensable for preventing excess ink (especially from sublimation) or adhesive from heat transfer vinyl (HTV) from sticking to the upper platen. This protects your press from permanent stains and prevents that residue from being accidentally transferred to your next project.

The Material Science Behind the Performance

The advantages of a PTFE sheet are not arbitrary; they are rooted in the unique chemical and physical properties of the material itself.

Exceptional Thermal Stability

PTFE is incredibly stable across a vast range of temperatures, easily withstanding the typical heat pressing range and beyond (from -270°C to +290°C). It will not melt, deform, or release harmful fumes at the temperatures used for garment decoration.

A True Non-Stick Surface

The material has an extremely low coefficient of friction and powerful anti-adhesion properties. This means almost nothing sticks to it, from stray inks and glues to melted synthetic fibers, ensuring a clean separation after every press.

Durability and Reusability

PTFE is chemically inert, meaning it resists damage from most solvents and cleaners. This chemical resistance, combined with its high flexural strength, makes the sheets incredibly durable. A single sheet can be wiped clean and reused for hundreds or even thousands of presses, making it a very economical tool.

Common Pitfalls and Considerations

While highly beneficial, using a PTFE sheet requires awareness of a few potential issues to ensure you get the best results.

Risk of Masking Pressure

The sheet adds a thin layer between the platen and your design. For some materials, you may need to slightly increase your pressure setting to compensate and ensure a proper bond.

Potential for Creasing

If the sheet itself is creased or wrinkled when you press, that crease can be subtly transferred onto your garment or vinyl. Always ensure the sheet is perfectly flat before closing the press.

Maintenance is Not Optional

To maintain its non-stick properties, the sheet must be kept clean. A simple wipe-down with a cloth after use is usually sufficient to remove any residue before it has a chance to build up.

Making the Right Choice for Your Goal

Integrating a PTFE sheet into your workflow is a simple step that pays significant dividends depending on your primary objective.

- If your primary focus is print quality: Use the sheet in every press to guarantee even heat distribution and prevent scorching on sensitive fabrics.

- If your primary focus is protecting your equipment: The sheet is your best defense against ink or adhesive buildup on your heat platen, extending its life and preventing cross-contamination between jobs.

- If your primary focus is cost-effectiveness: The sheet's reusability and ability to prevent costly mistakes (like ruined garments) provide an exceptional return on a very small investment.

Ultimately, a PTFE sheet is a small, inexpensive tool that protects your larger investments in materials, equipment, and time.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Non-Stick Surface | Prevents ink/adhesive transfer, protects equipment, ensures clean separation |

| High Heat Resistance | Withstands temperatures up to 290°C, prevents scorching and fabric damage |

| Durable & Reusable | Chemically inert, can be used for hundreds of presses, highly cost-effective |

| Even Heat Distribution | Eliminates hot spots for consistent, professional results on every project |

Upgrade your heat press process with precision-engineered PTFE sheets from KINTEK.

As specialists in high-performance PTFE components for demanding industries, we understand the critical need for reliability and consistency. Our PTFE heat press sheets are manufactured to the highest standards, ensuring the exceptional non-stick properties, thermal stability, and durability detailed in this article.

Whether you are in the garment decoration, industrial, or laboratory sector, KINTEK provides custom fabrication from prototypes to high-volume orders. Protect your equipment, enhance your product quality, and improve your bottom line.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the common applications of PTFE pneumatic valves? Ensure Purity and Chemical Resistance in Your Process

- What design parameters are specified for PTFE sliding bearings? Ensure Structural Safety and Performance

- What quality standards are followed in the manufacturing of Teflon-encapsulated O-Rings? Ensure Compliance for Critical Applications

- What are the disadvantages of PTFE gaskets? Key Limitations to Consider

- What is the function of PFA and PTFE lined check valves in chemical plants? Prevent Corrosive Backflow and Protect Equipment

- What temperature range can PTFE gaskets and sheets withstand? A Guide from -200°C to +260°C

- What is counter rotation in rotary seals and why is it problematic? Prevent Catastrophic Seal Failure

- Why are Teflon O-rings important in industrial applications? Achieve Unmatched Sealing Reliability