To be direct, Teflon O-rings are important in industrial applications because their unique combination of chemical inertness, extreme temperature stability, and low friction allows them to create reliable seals in harsh environments where nearly all other materials would quickly fail. This resilience prevents costly leaks, reduces equipment downtime, and ensures operational safety under demanding conditions.

The core value of Teflon in industrial settings is not just one property, but its ability to solve multiple engineering challenges simultaneously. It provides a robust sealing solution that withstands chemical attack, thermal stress, and mechanical wear, directly contributing to increased equipment lifespan and reliability.

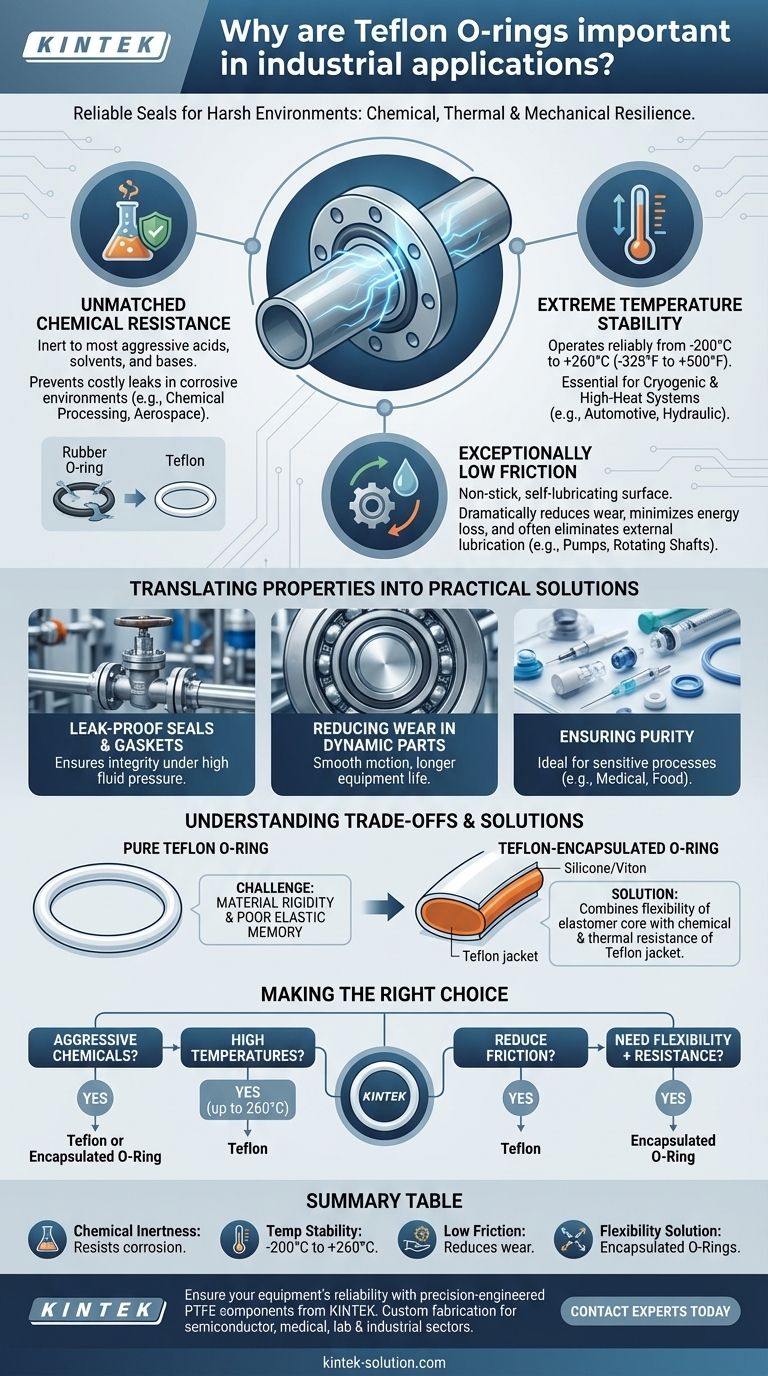

The Core Properties Defining Teflon's Industrial Value

To understand why Teflon (PTFE) is so indispensable, we must examine the specific material properties that set it apart. These characteristics are not just incremental improvements; they represent a fundamental advantage in certain applications.

Unmatched Chemical Resistance

Teflon is famously inert to most chemicals, including aggressive acids, solvents, and bases. This makes it the default choice for seals and gaskets in chemical processing plants, pharmaceutical manufacturing, and aerospace systems where exposure to corrosive fluids is constant.

Where a standard rubber O-ring would degrade and fail, a Teflon seal maintains its structural integrity, preventing dangerous leaks.

Extreme Temperature Stability

Teflon O-rings and seals perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This thermal stability is critical in applications like automotive engines, high-pressure hydraulic systems, and cryogenic equipment.

This ensures the seal remains effective and does not become brittle at low temperatures or degrade at high temperatures.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, making it inherently non-stick and self-lubricating. In dynamic applications with moving parts, such as in pumps or rotating shafts, this property is vital.

It dramatically reduces wear and tear on machinery components, minimizes energy loss due to friction, and often eliminates the need for external lubrication, which simplifies design and reduces maintenance.

Translating Properties into Practical Applications

These fundamental properties directly translate into solutions for common and critical industrial challenges, from sealing fluids to protecting machinery.

Creating Leak-Proof Seals and Gaskets

The primary function of an O-ring is to create a reliable seal. In industrial fluid power and high-pressure systems, Teflon's durability ensures a leak-proof connection that resists both the contained fluid and the operational pressures.

Reducing Wear in Bearings and Bushings

In machinery, Teflon bushings and bearings manage motion between components. Their low-friction surface allows parts to move smoothly with minimal resistance, preventing mechanical wear and extending the equipment's operational life.

Ensuring Purity in Sensitive Processes

Because Teflon is inert and non-reactive, it is an ideal material for medical devices and food processing equipment. It does not contaminate the materials it comes into contact with, ensuring the purity of the final product.

Understanding the Trade-offs and Solutions

While Teflon's properties are exceptional, it is not a universal solution. Understanding its limitations is key to using it effectively.

The Challenge of Material Rigidity

Pure, solid Teflon is a relatively rigid plastic. Unlike rubber elastomers, it has poor "elastic memory," meaning it does not spring back to its original shape as effectively after being compressed. This can make it a less-than-ideal choice for applications requiring a highly flexible seal.

The Solution: Encapsulated O-Rings

To overcome this limitation, engineers developed the Teflon-encapsulated O-ring. This design combines a flexible inner core made of an elastomer (like Silicone or Viton) with a thin, protective outer jacket of Teflon.

This hybrid approach provides the best of both worlds: the excellent flexibility and compression of the rubber core and the superior chemical and temperature resistance of the Teflon exterior.

Making the Right Choice for Your Application

Selecting the correct sealing material is critical for ensuring system integrity and longevity. Your decision should be guided by the primary demands of your specific environment.

- If your primary focus is sealing against aggressive chemicals: A Teflon or Teflon-encapsulated O-ring is the safest and most reliable choice.

- If your primary focus is high-temperature performance: Teflon's stability up to 260°C (500°F) makes it superior to most standard elastomers.

- If your primary focus is reducing friction in a dynamic system: The self-lubricating nature of Teflon will minimize wear and reduce maintenance requirements.

- If you need both chemical resistance and high flexibility: An encapsulated O-ring is the ideal solution, combining an elastomeric core with a protective Teflon jacket.

Ultimately, choosing the right material ensures your equipment operates reliably, safely, and efficiently under its most demanding conditions.

Summary Table:

| Key Property | Benefit in Industrial Applications |

|---|---|

| Chemical Inertness | Resists corrosive acids, solvents, and bases; ideal for chemical processing. |

| Extreme Temperature Stability | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Friction / Self-Lubricating | Reduces wear in dynamic applications, minimizes maintenance. |

| Solution for Flexibility (Encapsulated O-Rings) | Combines Teflon's resilience with an elastomer's flexibility. |

Ensure your equipment's reliability with precision-engineered PTFE components from KINTEK.

Whether you are in the semiconductor, medical, laboratory, or industrial sector, the right seal is critical for preventing leaks, reducing downtime, and ensuring safety. KINTEK specializes in manufacturing high-quality PTFE components—including seals, liners, and labware—tailored to withstand your most demanding conditions.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Ready to solve your toughest sealing challenges? Contact our experts today to discuss your project needs and discover how our PTFE solutions can enhance your operational efficiency and product lifespan.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments