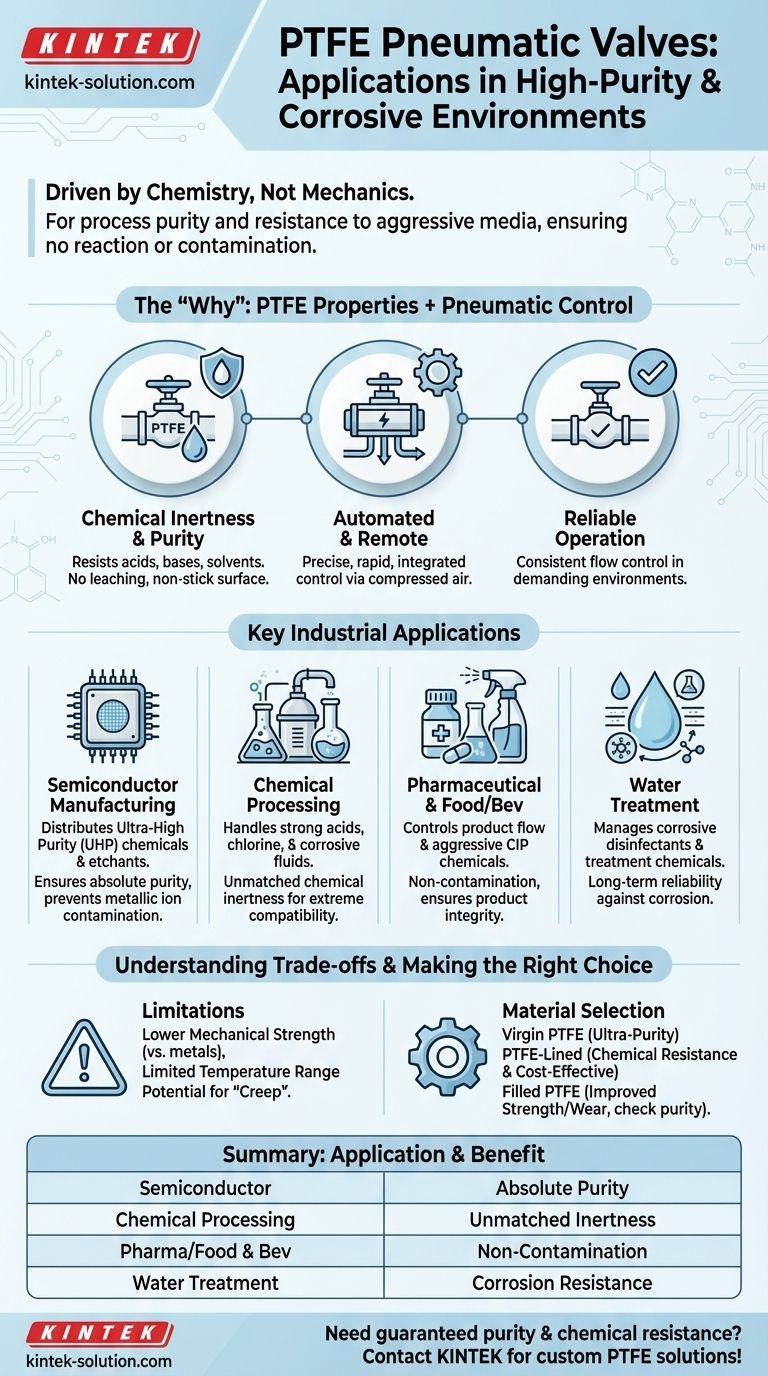

At its core, PTFE pneumatic valves are specified for applications where process purity and resistance to aggressive chemicals are non-negotiable. Their most common uses are in semiconductor manufacturing, chemical processing, pharmaceutical production, and food and beverage industries, where they are used to automatically control the flow of highly corrosive or ultra-pure fluids.

The decision to use a PTFE pneumatic valve is driven by chemistry, not mechanics. You choose it when the primary goal is to prevent any reaction or contamination between the valve and the fluid it controls, leveraging pneumatic actuation for reliable, automated operation.

The Defining Properties of PTFE in Valve Design

To understand why these valves are used in such specific contexts, we must look at the unique characteristics of Polytetrafluoroethylene (PTFE) itself, combined with the function of pneumatic control.

Unmatched Chemical Inertness

The single most important property of PTFE is its near-total chemical inertness. It is resistant to almost all acids, bases, solvents, and corrosive agents.

This makes it the default material choice for handling aggressive media that would rapidly degrade even high-grade metal alloys.

High Purity and Non-Contamination

PTFE is an extremely pure polymer that does not leach contaminants into the media it contacts. Its surface is also famously non-stick.

This is critical in semiconductor manufacturing and pharmaceuticals, where even parts-per-billion levels of contamination can compromise an entire production batch.

Automated and Remote Control

The "pneumatic" aspect refers to the method of actuation. These valves are opened and closed using compressed air, not by hand.

This allows for precise, rapid, and remote control integrated into an automated process system, which is essential for modern manufacturing and chemical plants.

Key Industrial Applications in Detail

The combination of inertness, purity, and automation makes these valves indispensable in several key sectors.

Semiconductor Manufacturing

In the fabrication of microchips, valves are used to distribute ultra-high purity (UHP) chemicals and aggressive etchants. A standard metal valve would corrode and introduce metallic ion contamination, ruining the sensitive electronic components. PTFE valves ensure absolute purity.

Chemical Processing and Distribution

This is the broadest application. PTFE valves and PTFE-lined valves are used throughout chemical plants, petrochemical facilities, and pulp and paper mills to handle substances like strong acids, chlorine, and other corrosive fluids that demand extreme material compatibility.

Pharmaceutical and Food & Beverage

In these industries, the primary concern is preventing any interaction with the product. PTFE valves ensure that the final product is not tainted and that the valve material itself is not degraded by aggressive cleaning-in-place (CIP) chemicals and sanitizers.

Water Treatment

Municipal and industrial water treatment facilities use powerful disinfectants and chemicals to ensure water safety. PTFE valves provide reliable, long-term flow control for these corrosive treatment chemicals, where metal components would fail over time.

Understanding the Trade-offs and Limitations

While exceptional in its niche, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Lower Mechanical Strength

Compared to metals like stainless steel, PTFE is a much softer material. It is more susceptible to scratching and has significantly lower pressure ratings.

Limited Temperature Range

PTFE has a narrower operating temperature window than metal. High temperatures can cause the material to soften and "creep," potentially compromising the valve's seal over time.

The Role of "Filled" PTFE

To overcome mechanical weaknesses, PTFE is often blended with fillers like glass fiber, carbon, or bronze. This "filled PTFE" offers improved strength and wear resistance but at a cost. The fillers can compromise the absolute purity of virgin PTFE, making it unsuitable for the most sensitive semiconductor or pharmaceutical applications.

Making the Right Choice for Your Goal

Selecting the correct valve material is a critical engineering decision based on your primary process requirement.

- If your primary focus is ultra-high purity: Virgin, unfilled PTFE is the necessary choice to prevent any process contamination, especially in semiconductor and biotech applications.

- If your primary focus is aggressive chemical resistance: A PTFE-lined valve, where a PTFE layer protects a stronger metal body, offers a durable and cost-effective solution for handling corrosive media.

- If you need improved mechanical or thermal performance: Consider a filled PTFE valve, but you must validate that the filler material will not leach and contaminate your specific process fluid.

Ultimately, choosing a PTFE pneumatic valve is a decision to prioritize chemical inertness and process purity above all other factors.

Summary Table:

| Industry | Primary Application | Key Benefit of PTFE Valve |

|---|---|---|

| Semiconductor | Distributing ultra-high purity (UHP) chemicals and etchants | Absolute purity, prevents contamination |

| Chemical Processing | Handling strong acids, chlorine, and corrosive fluids | Unmatched chemical inertness |

| Pharmaceutical & Food & Beverage | Controlling product flow and aggressive CIP chemicals | Non-contamination, chemical resistance |

| Water Treatment | Managing corrosive disinfectants and treatment chemicals | Long-term reliability, corrosion resistance |

Need a PTFE pneumatic valve that guarantees purity and chemical resistance for your application?

At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we understand the critical need for valves that prevent contamination and withstand aggressive media.

We offer custom fabrication from prototypes to high-volume orders, ensuring your specific requirements for material purity (virgin or filled PTFE) and performance are met. Let us provide you with a reliable solution that enhances your process integrity and efficiency.

Contact KINTEK today to discuss your valve needs and get a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How can Teflon packing be enhanced for specific applications? Tailor PTFE for Superior Performance

- How is PTFE used in the semi-conductor industry? Essential for Purity and Performance

- What types of PTFE machined parts are commonly produced? Essential Components for Demanding Industries

- Why are PTFE gaskets suitable for food processing plants? Ensure Purity & Compliance

- What types of products can be made from PTFE sheets in the chemical industry? | Gaskets, Liners & Seals

- What are the main differences between PTFE lined butterfly valves and hard seal butterfly valves? Choose the Right Seal for Your Application

- In which industries are PTFE gland packings commonly used? For Purity, Chemical Resistance & Reliability

- How do Teflon bushes perform in chemically harsh environments? Unmatched Chemical Resistance for Critical Applications