Counter rotation in a rotary seal is a critical failure mode where the part of the seal designed to be stationary breaks loose and rotates with the shaft. This occurs when the friction at the dynamic sealing surface (the shaft) becomes greater than the seal's static grip within its housing. The result is catastrophic, as the seal is forced to wear against a surface not prepared for motion, causing rapid degradation and leakage.

The core issue is a reversal of roles. Counter rotation happens when it becomes easier for the entire seal to spin in its housing than for the dynamic lip to slide against the shaft, leading to swift and predictable failure.

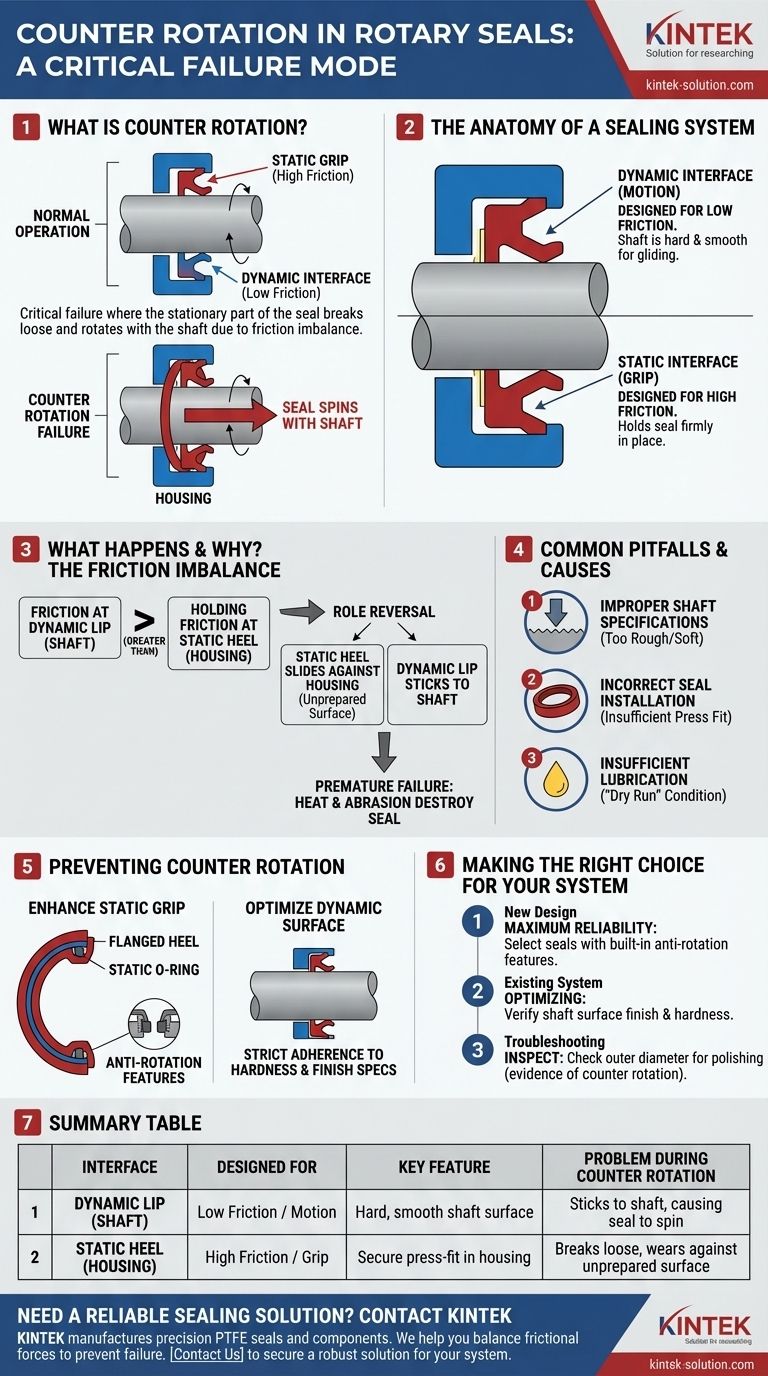

The Anatomy of a Sealing System

To understand this failure, you must first understand the two distinct jobs a rotary seal performs simultaneously. Each interface is engineered for a completely different purpose.

The Dynamic Interface: Designed for Motion

The primary sealing action happens at the dynamic lip, which presses against the rotating shaft.

This interface is designed for low friction and high wear resistance. The shaft surface is intentionally made very hard and smooth to allow the seal lip to glide over it for millions of revolutions with minimal wear.

The Static Interface: Designed for Grip

The outer part of the seal, often called the heel, is pressed into a stationary housing or bore.

This interface is designed for high friction and a secure grip. Its job is to hold the seal firmly in place, preventing it from moving or spinning under any operational forces.

What Happens During Counter Rotation?

Counter rotation is the result of an unintended imbalance in frictional forces, causing the system to take the path of least resistance.

The Friction Imbalance

This failure begins when the friction at the dynamic lip (against the shaft) exceeds the holding friction of the static heel (in the housing).

A number of factors can cause this, such as insufficient lubrication, an overly rough shaft surface, or high pressure that forces the lip too hard against the shaft.

The Role Reversal

When this friction tipping point is reached, the static heel "breaks loose" from the housing. The entire seal begins to spin with the shaft.

The part of the seal designed to grip is now sliding, and the part designed to slide is stuck to the shaft.

The Consequence: Premature Failure

This role reversal is fatal for the seal. The housing surface is typically much softer and has a poorer surface finish than the shaft.

Forcing the seal's static heel to rub against this unprepared surface generates immense heat and abrasion, quickly destroying the seal material and causing a complete loss of function.

Common Pitfalls and Causes

Counter rotation is a system problem, not just a seal defect. Understanding the common causes is the key to preventing it.

Improper Shaft Specifications

The single most common cause is a shaft that is not properly prepared. A surface that is too rough will act like sandpaper on the seal lip, dramatically increasing dynamic friction. A shaft that is too soft will wear quickly, creating a poor sealing surface.

Incorrect Seal Installation

A seal that is not properly seated or is installed in an oversized housing will have insufficient "press fit" or "squeeze." This provides a weak static grip, making it much easier for the seal to break loose and spin.

Insufficient Lubrication

Lubrication is critical for minimizing friction and heat at the dynamic sealing lip. A "dry run" condition, even for a short time, can cause friction to spike and initiate counter rotation.

Preventing Counter Rotation Through Design

Effective prevention focuses on ensuring the static friction in the housing is always significantly higher than the dynamic friction at the shaft.

Enhancing the Static Grip

Seal manufacturers have developed specific features to lock the seal in place. These include flanged heels that provide a mechanical interlock, integrated static O-rings that increase holding force, or proprietary designs that add anti-rotation features.

Optimizing the Dynamic Surface

Strict adherence to the specified shaft hardness and surface finish is non-negotiable. A smooth, hard surface is the best defense against high dynamic friction, ensuring the seal lip can perform its job as intended.

Making the Right Choice for Your System

Choosing the right approach depends on your system's requirements and operational environment.

- If your primary focus is maximum reliability in a new design: Select a seal with built-in anti-rotation features like a flanged heel or static O-ring to mechanically prevent movement.

- If your primary focus is optimizing an existing system: Double-check that your shaft's surface finish and hardness meet or exceed the seal manufacturer's specifications.

- If you are troubleshooting a seal failure: Inspect the seal's outer diameter for signs of polishing or wear; this is the definitive evidence of counter rotation.

By correctly balancing the frictional forces in your design, you can engineer a sealing system that is robust, reliable, and immune to this fundamental failure mode.

Summary Table:

| Interface | Designed For | Key Feature | Problem During Counter Rotation |

|---|---|---|---|

| Dynamic Lip (Shaft) | Low Friction / Motion | Hard, smooth shaft surface | Sticks to shaft, causing seal to spin |

| Static Heel (Housing) | High Friction / Grip | Secure press-fit in housing | Breaks loose, wears against unprepared surface |

Need a reliable sealing solution for your demanding application?

Counter rotation is a critical failure mode that can halt your operations. At KINTEK, we manufacture precision PTFE seals and components designed to withstand the toughest conditions in the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your seals have the precise fit and anti-rotation features needed for maximum reliability. We help you balance frictional forces to prevent failure before it starts.

Contact KINTEK today to discuss your specific requirements and secure a robust sealing solution for your system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability