At its core, the function of a PFA or PTFE lined check valve in a chemical plant is to serve as a crucial one-way gate for highly corrosive fluids. These valves automatically prevent reverse flow, or backflow, within a piping system, while their specialized lining provides an inert barrier that protects the valve's structural components from chemical attack. This dual function is essential for protecting equipment, ensuring process purity, and maintaining operational safety.

The central purpose of these valves is not just to control flow direction, but to do so reliably in environments where standard metal valves would rapidly corrode and fail. The choice between PFA and PTFE lining is determined by the specific demands of the application, such as temperature, pressure, and mechanical stress.

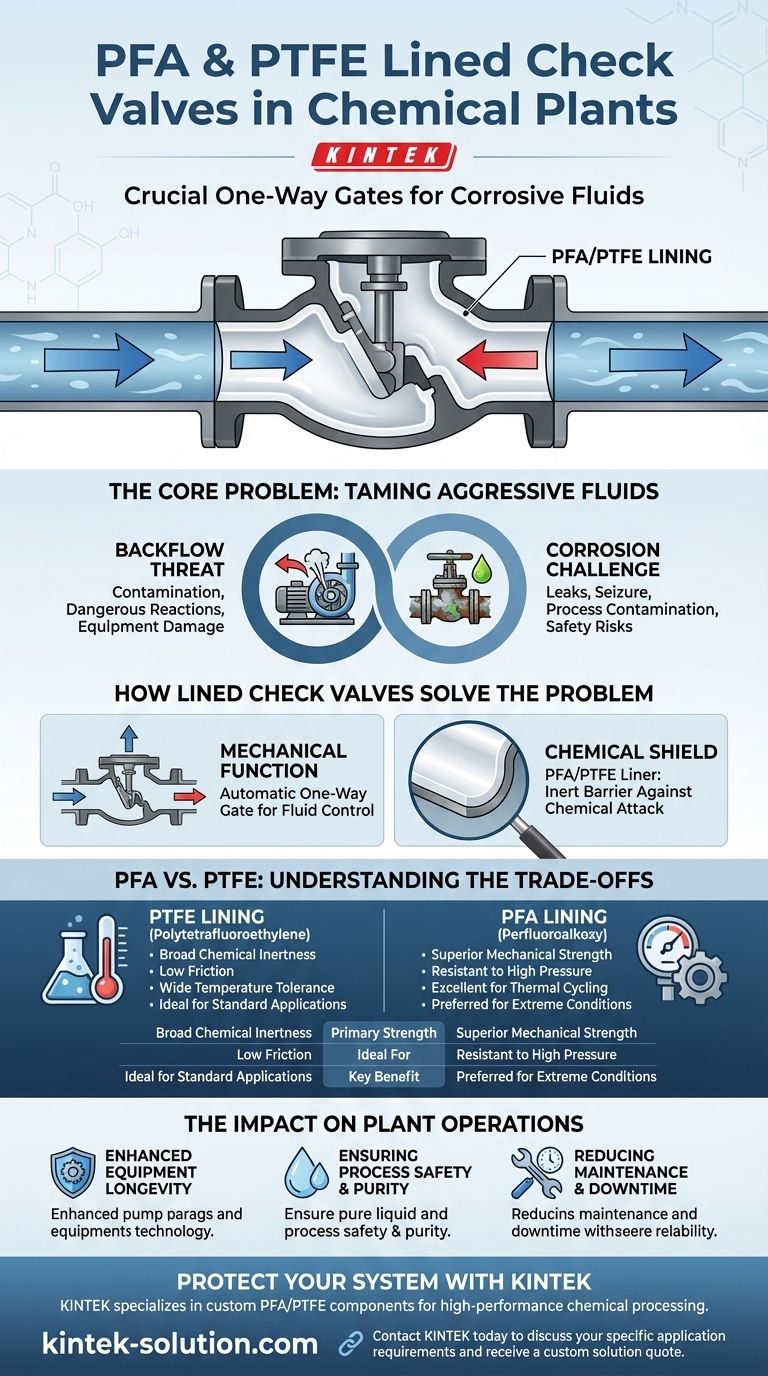

The Core Problem: Taming Aggressive Fluids

In chemical processing, fluids are often highly reactive and are moved under precise conditions. Two constant threats to any piping system are backflow and corrosion.

The Danger of Backflow

Backflow is the unwanted reversal of fluid in a pipe. It can cause catastrophic damage by contaminating a previous stage of a process, creating dangerous chemical reactions, or damaging sensitive upstream equipment like pumps and meters that are not designed to handle reverse pressure.

The Challenge of Corrosion

Chemicals such as strong acids, alkalis, and salts are inherently corrosive to most metals. A standard steel or iron valve would quickly degrade and fail, leading to leaks, equipment seizure, and process contamination, which poses significant safety and financial risks.

How Lined Check Valves Solve the Problem

PFA and PTFE lined check valves are engineered specifically to counteract these two threats simultaneously through a combination of mechanical design and material science.

The Mechanical Function: The Check Valve

The "check valve" component is a simple, automatic mechanism. It is designed to open with minimal forward pressure from the flowing fluid. If the flow stops or attempts to reverse, the valve closes automatically, ensuring the fluid can only move in one direction.

The Chemical Shield: The PFA/PTFE Lining

The true innovation is the lining. PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene) are fluoropolymers with exceptional properties.

The entire wetted surface of the valve—the parts that touch the fluid—is coated with a thick, seamless layer of one of these materials. This lining effectively isolates the corrosive chemical from the valve's metal body, preventing any chemical attack. Furthermore, these materials have a smooth, non-stick surface that resists the buildup of deposits, ensuring consistent operation.

Understanding the Trade-offs: PFA vs. PTFE

While both materials offer outstanding chemical resistance, they have distinct properties that make them suitable for different operating conditions.

When to Choose PTFE

PTFE is renowned for its near-universal chemical inertness, extremely low friction, and broad temperature tolerance. It is a highly reliable and versatile choice for a wide range of corrosive chemical services under standard operating conditions.

When to Choose PFA

PFA shares the chemical resistance of PTFE but offers superior mechanical strength. It is more resistant to the stresses of high pressure and frequent thermal cycling (shifts between hot and cold). This makes PFA the preferred choice for more extreme or demanding applications where mechanical durability is as critical as chemical resistance.

The Impact on Plant Operations

The correct implementation of these valves has a profound, positive impact on the entire facility.

Enhancing Equipment Longevity

By preventing corrosive backflow, these valves act as bodyguards for expensive upstream equipment like pumps, reactors, and instrumentation, shielding them from damage and significantly extending their service life.

Ensuring Process Safety and Purity

Unidirectional flow is critical for maintaining the integrity of a chemical process. Lined check valves prevent cross-contamination between different stages, which is essential for producing a pure final product and avoiding unintended, hazardous reactions.

Reducing Maintenance and Downtime

The high durability of PFA and PTFE linings means the valves last longer and require less frequent replacement. This directly translates to reduced maintenance costs and, more importantly, less unplanned plant downtime.

Making the Right Choice for Your Application

Selecting the appropriate valve is a critical engineering decision. Use the following guidelines to inform your choice.

- If your primary focus is broad corrosion resistance for standard applications: PTFE-lined check valves provide excellent, cost-effective performance and chemical inertness.

- If your primary focus is handling extreme temperatures, high pressures, or severe thermal cycling: PFA-lined check valves offer the superior mechanical strength and creep resistance required for these demanding conditions.

- If your primary focus is protecting critical upstream equipment from failure: A properly specified PFA or PTFE lined check valve is non-negotiable to prevent costly damage from corrosive backflow.

Ultimately, selecting the correct lined check valve is a foundational step in building a safe, reliable, and efficient chemical processing system.

Summary Table:

| Feature | PTFE Lining | PFA Lining |

|---|---|---|

| Primary Strength | Broad chemical inertness, low friction | Superior mechanical strength, thermal cycling resistance |

| Ideal For | Standard applications, cost-effective corrosion resistance | High pressure, extreme temperatures, demanding conditions |

| Key Benefit | Versatile reliability for a wide range of chemicals | Enhanced durability for severe operating environments |

Protect your chemical processing system with precision-engineered PTFE and PFA components from KINTEK.

Choosing the right lined check valve is critical for preventing costly downtime and equipment failure. KINTEK specializes in the custom fabrication of high-performance PTFE and PFA components—including seals, liners, labware, and valves—for the semiconductor, medical, laboratory, and industrial sectors.

We combine superior material science with precision manufacturing, from prototypes to high-volume orders, to deliver solutions that ensure your system's safety, purity, and reliability.

Contact KINTEK today to discuss your specific application requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications