Polytetrafluoroethylene (PTFE) is a premier material for custom parts because of its exceptionally rare combination of high-performance properties. Its primary advantages are an extremely low coefficient of friction, near-total chemical inertness, high-temperature resistance, and excellent electrical insulation, all retained even when precisely machined into complex shapes.

The true value of PTFE for custom components isn't just one of its properties, but its remarkable versatility. Its ability to be machined to tight tolerances while retaining elite performance against friction, chemicals, and heat allows it to solve complex engineering challenges where other materials fail.

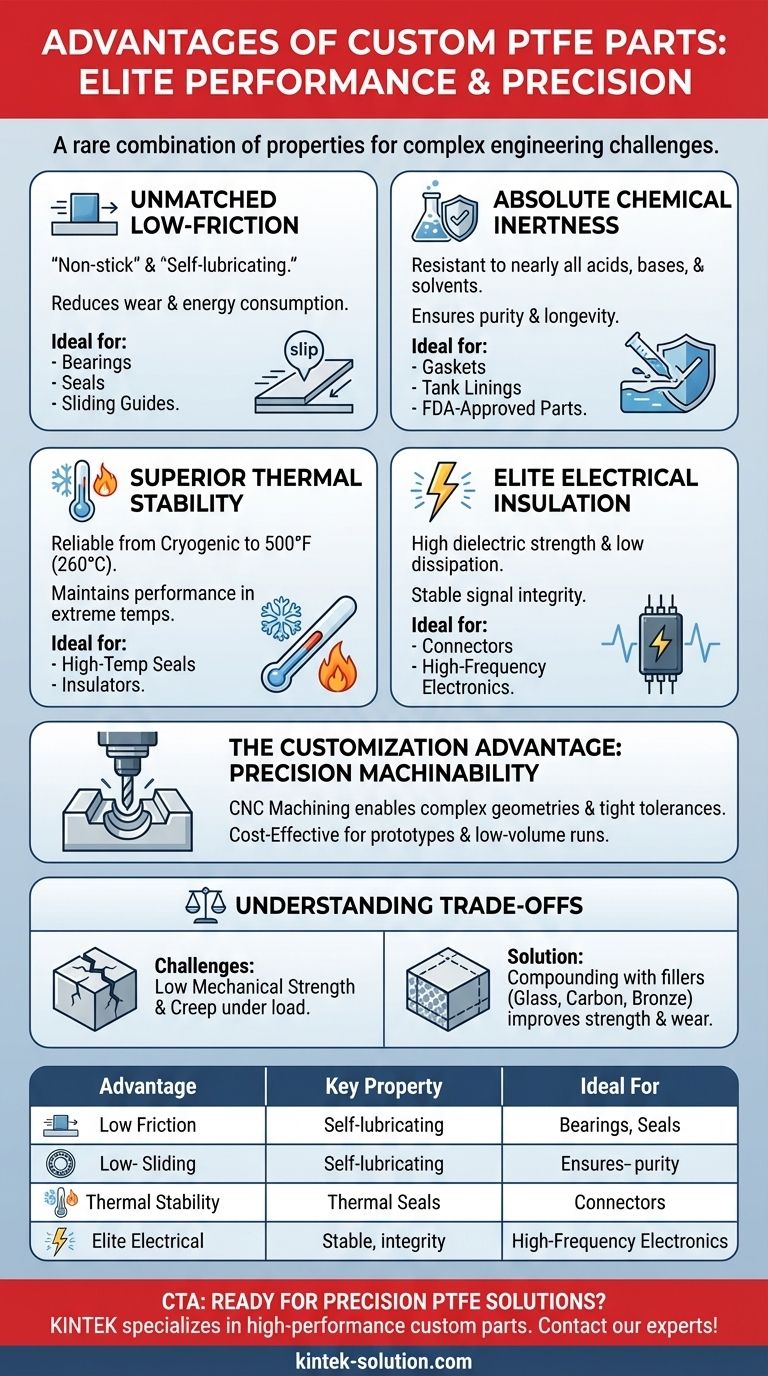

Why PTFE Excels in Demanding Environments

To understand the value of custom PTFE parts, we must look at the specific problems its core properties solve in industrial and technical applications.

Unmatched Low-Friction Performance

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This is often referred to as its "non-stick" or "self-lubricating" characteristic.

This property is critical for parts that slide against each other, as it dramatically reduces wear and energy consumption. It makes PTFE an ideal choice for custom bearings, seals, and sliding guides that require smooth operation without external lubricants.

Absolute Chemical Inertness

PTFE is chemically inert, meaning it is resistant to nearly all industrial chemicals, acids, and bases. It does not degrade or swell when exposed to corrosive substances.

This makes it indispensable in chemical processing, pharmaceutical manufacturing, and food and beverage industries. Custom parts like gaskets, tank linings, and fluid-handling components made from PTFE ensure purity and longevity in harsh environments. Many grades are also FDA-approved for direct food contact.

Superior Thermal Stability

PTFE components perform reliably across an exceptionally wide temperature range. They can withstand continuous service temperatures up to 500°F (260°C) without significant degradation.

This high heat resistance allows PTFE to be used in applications like high-temperature seals and insulators. It also maintains flexibility at cryogenic temperatures, adding to its operational versatility.

Elite Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength and low a dissipation factor. Its insulating properties remain stable across a wide range of frequencies and temperatures.

This makes it a top-tier material for custom electrical insulators, connectors, and components used in high-frequency electronics where signal integrity is paramount.

The Customization Advantage: Machinability

A material's properties are only useful if it can be formed into the required shape. PTFE's excellent machinability is what unlocks its potential for custom solutions.

Precision Through CNC Machining

PTFE is a relatively soft polymer that can be easily and precisely machined using standard CNC (Computer Numerical Control) equipment.

This allows for the creation of highly complex geometries and parts with very tight tolerances, ensuring a perfect fit for specialized applications like precision O-rings, custom valve seats, and unique insulators.

Cost-Effective for Customization

Compared to creating expensive molds for injection molding, machining PTFE is often more affordable for producing prototypes, low-volume runs, or highly customized parts. This makes it an accessible option for solving unique operational challenges without a massive initial investment.

Understanding the Trade-offs

No material is perfect, and objectivity requires acknowledging PTFE's limitations. Understanding these trade-offs is key to successful application.

Low Mechanical Strength

While durable in many respects, pure PTFE is a relatively soft material with low tensile strength and abrasion resistance compared to engineering plastics like PEEK or Nylon. It is not suitable for high-load structural components on its own.

Tendency to Creep

PTFE is susceptible to "creep" or "cold flow," meaning it can slowly deform over time when subjected to a constant load, especially at elevated temperatures. This must be a key consideration in the design of high-pressure seals or load-bearing components.

Solutions Through Compounding

To mitigate these mechanical weaknesses, PTFE is often compounded with fillers like glass fiber, carbon, or bronze. These additives can significantly improve compressive strength, wear resistance, and creep resistance, though they may slightly alter other properties like chemical resistance or coefficient of friction.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary challenge you need to solve.

- If your primary focus is reducing friction and wear: PTFE's self-lubricating nature makes it an ideal choice for custom bearings, seals, and sliding components that must operate smoothly.

- If your primary focus is chemical compatibility: Its near-total chemical inertness ensures unmatched reliability in corrosive environments found in chemical processing or food applications.

- If your primary focus is thermal and electrical performance: PTFE's stability across a wide temperature range and its excellent dielectric properties make it a go-to material for insulators in extreme conditions.

- If your primary focus is a high-load structural part: You should evaluate filled PTFE grades or alternative high-strength polymers, as pure PTFE's softness may not provide the required mechanical integrity.

Ultimately, PTFE's value lies in its unique ability to be precision-engineered for specific problems that demand extreme performance and reliability.

Summary Table:

| Advantage | Key Property | Ideal For |

|---|---|---|

| Low Friction | Self-lubricating, non-stick | Bearings, seals, sliding guides |

| Chemical Inertness | Resistant to nearly all chemicals | Chemical processing, FDA food contact parts |

| Thermal Stability | Withstands up to 500°F (260°C) | High-temperature seals, insulators |

| Electrical Insulation | High dielectric strength, stable across frequencies | Electrical connectors, high-frequency components |

Ready to solve your unique engineering challenges with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance custom PTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in CNC machining ensures your custom prototypes or high-volume orders meet the tightest tolerances while maintaining PTFE's elite properties.

Let us help you leverage PTFE's unique advantages for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications