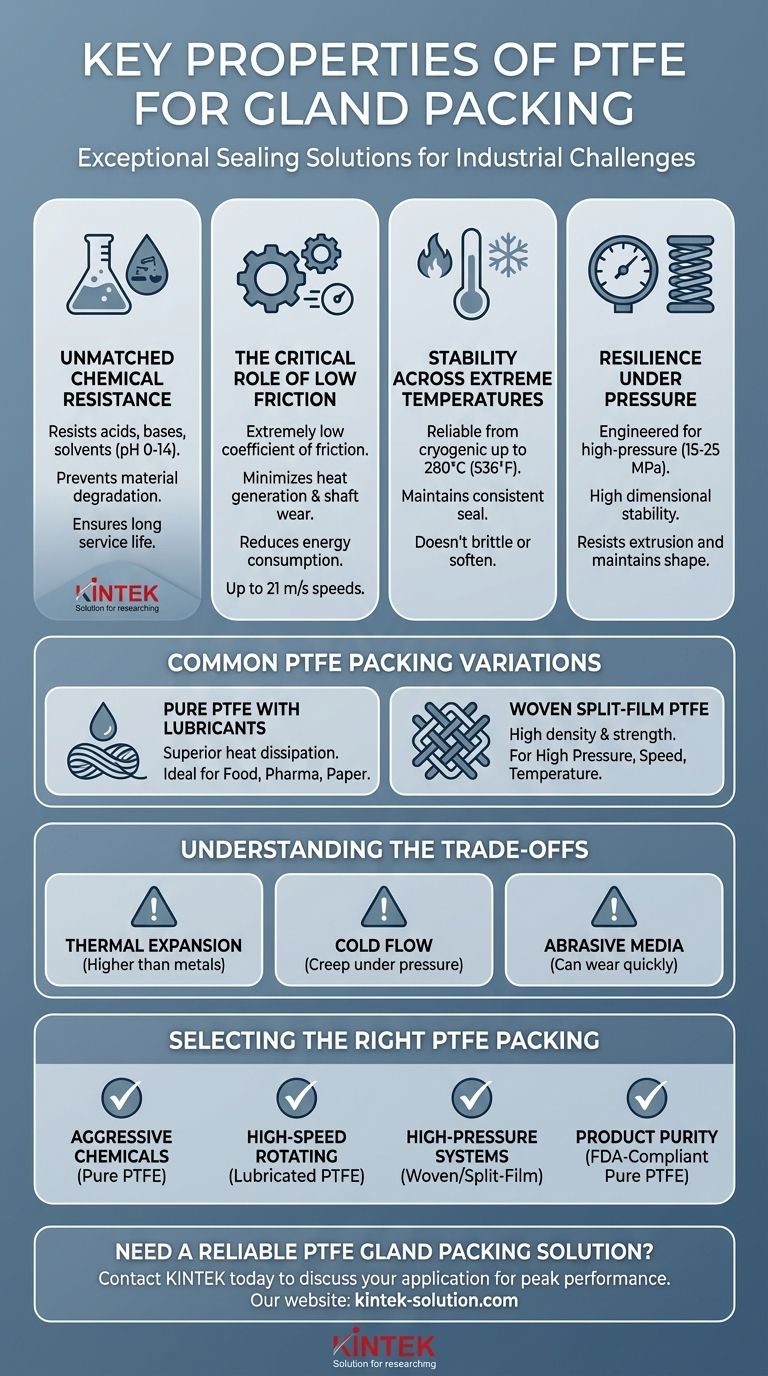

The primary properties of PTFE that make it exceptional for gland packing are its near-universal chemical resistance, an extremely low coefficient of friction, and a wide operational temperature range. This unique combination allows PTFE packing to form a durable, low-wear seal that can withstand harsh industrial environments without degrading or damaging equipment.

PTFE isn't just a material; it's a problem-solver for industrial seals. Its unique combination of chemical inertness, low friction, and thermal stability directly counters the three main causes of gland packing failure: chemical degradation, abrasive wear, and thermal breakdown.

Why PTFE Excels as a Sealing Material

To understand the value of PTFE in gland packing, we must look at how its core characteristics solve specific challenges faced in industrial pumps, valves, and other rotating equipment.

Unmatched Chemical Resistance

Gland packing is often exposed to highly aggressive substances. PTFE's chemical inertness is its most significant advantage in these situations.

It is resistant to a vast spectrum of media, including strong acids (like nitric and sulfuric acid), bases, solvents, and corrosive gases. This ensures the packing material does not dissolve, swell, or weaken, maintaining a reliable seal over a long service life. Its effectiveness spans the entire pH range of 0 to 14.

The Critical Role of Low Friction

Gland packing is in constant contact with a moving shaft. High friction can generate excessive heat, score the shaft surface, and increase energy consumption.

PTFE has one of the lowest coefficients of friction of any solid material. This property dramatically reduces the heat generated, even at high line speeds (up to 21 m/s). More importantly, it minimizes wear and tear on the shaft, preventing costly damage and extending the life of the equipment. This also leads to a reduction in the power required to operate the machinery.

Stability Across Extreme Temperatures

Industrial processes often involve fluids that are either very hot or very cold. The packing material must maintain its physical properties to prevent leaks.

PTFE remains stable and effective across a broad temperature range, with some variants performing reliably up to 280°C (536°F). It doesn't become brittle at low temperatures or soften and extrude at high temperatures, ensuring a consistent and dependable seal despite thermal fluctuations.

Resilience Under Pressure

The packing must withstand the system's internal pressure without being forced out of place.

PTFE packing is engineered for high-pressure applications, typically handling 15 to 25 MPa. Specially constructed packings, such as those made from woven split-film PTFE, offer high dimensional stability and resistance to compression, maintaining their shape and density to prevent leaks under significant force.

Common PTFE Packing Variations

Not all PTFE packing is the same. The base material is often enhanced to optimize performance for specific applications.

Pure PTFE with Lubricants

For high-speed applications, pure PTFE yarn is often impregnated with a special lubricant, such as silicone oil.

This treatment further lowers the friction coefficient, providing superior heat dissipation. It is an ideal choice for industries like food, pharmaceuticals, and paper manufacturing, where product contamination from the packing material must be avoided.

Woven Split-Film PTFE

This variant is constructed from multiple PTFE yarns that have been sintered (heat-treated) and stretched before being woven together.

The result is a packing with very high density, structural strength, and resistance to extrusion. This makes it suitable for the most demanding conditions involving a combination of high pressure, high speed, and high temperature.

Understanding the Trade-offs

While PTFE is a superior material for many applications, no single solution is perfect. Acknowledging its limitations is key to using it effectively.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. Significant temperature swings can cause it to expand or contract, which may affect the seal's integrity if not accounted for during installation and tensioning.

Cold Flow (Creep)

Under sustained high pressure and at ambient temperatures, pure PTFE can exhibit a tendency to "creep" or slowly deform over time. This can cause the packing to loosen. Using reinforced or densely woven PTFE variants helps mitigate this effect in high-pressure systems.

Abrasive Media

PTFE is a relatively soft material. While it excels against chemicals, it can wear quickly when used to seal fluids containing hard, abrasive particles like sand or slurries. In such cases, a harder packing material might be a more durable choice.

Selecting the Right PTFE Packing for Your Application

Choosing the correct variant is critical for maximizing performance and equipment life.

- If your primary focus is aggressive chemicals: Pure, dense PTFE packing provides the most comprehensive chemical resistance across the entire pH scale.

- If your primary focus is high-speed rotating equipment: Choose a PTFE packing impregnated with a lubricant like silicone oil to minimize friction, heat generation, and shaft wear.

- If your primary focus is high-pressure systems: A split-film or woven PTFE packing offers the structural strength and extrusion resistance needed to maintain a reliable seal.

- If your primary focus is product purity (food/pharma): Use a pure PTFE packing or one treated with FDA-compliant lubricants to prevent any contamination.

By matching the specific properties and type of PTFE packing to your operational demands, you ensure a durable, efficient, and reliable seal.

Summary Table:

| Key Property | Benefit for Gland Packing |

|---|---|

| Chemical Resistance | Resists acids, bases, solvents (pH 0-14); prevents degradation. |

| Low Coefficient of Friction | Reduces heat, shaft wear, and energy consumption. |

| Wide Temperature Range | Stable performance from cryogenic up to 280°C (536°F). |

| High-Pressure Resilience | Handles 15-25 MPa; resists extrusion. |

Need a reliable PTFE gland packing solution tailored to your specific industrial challenges?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom gland packing for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures a seal that maximizes equipment life and operational efficiency.

Contact us today to discuss your application and receive a solution designed for peak performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What nominal sizes are available for PTFE gaskets? From DN15 to DN2000 and Beyond

- What are the limitations of PTFE in ball valve seat applications? Avoid Costly Seal Failures

- Why is PTFE the preferred material for bellows and diaphragms? Unmatched Chemical, Thermal, and Mechanical Stability

- What role does Teflon play in automotive applications? Enhancing Durability & Performance in Harsh Environments

- What factors are important when selecting PTFE O-ring seals? Ensure Long-Term Reliability in Harsh Environments

- What are PTFE seals and what makes them exceptional? Unmatched Performance in Extreme Conditions

- What are the limitations of PTFE in terms of fabrication? Navigating Manufacturing Challenges

- What design considerations are important when working with CNC machined PTFE parts? Master Tolerances, Creep, and Thermal Expansion