At their core, PTFE Teflon washers are defined by four exceptional properties: extreme chemical resistance, a wide temperature tolerance, an incredibly low coefficient of friction, and excellent electrical insulation. These characteristics make them a premier choice for demanding applications where conventional materials would corrode, melt, or seize.

The true value of a PTFE washer is not just one of its properties, but its unique ability to combine chemical inertness and an extremely "slippery" surface. This makes it an essential component in environments that are simultaneously corrosive, high-temperature, and require smooth, reliable movement.

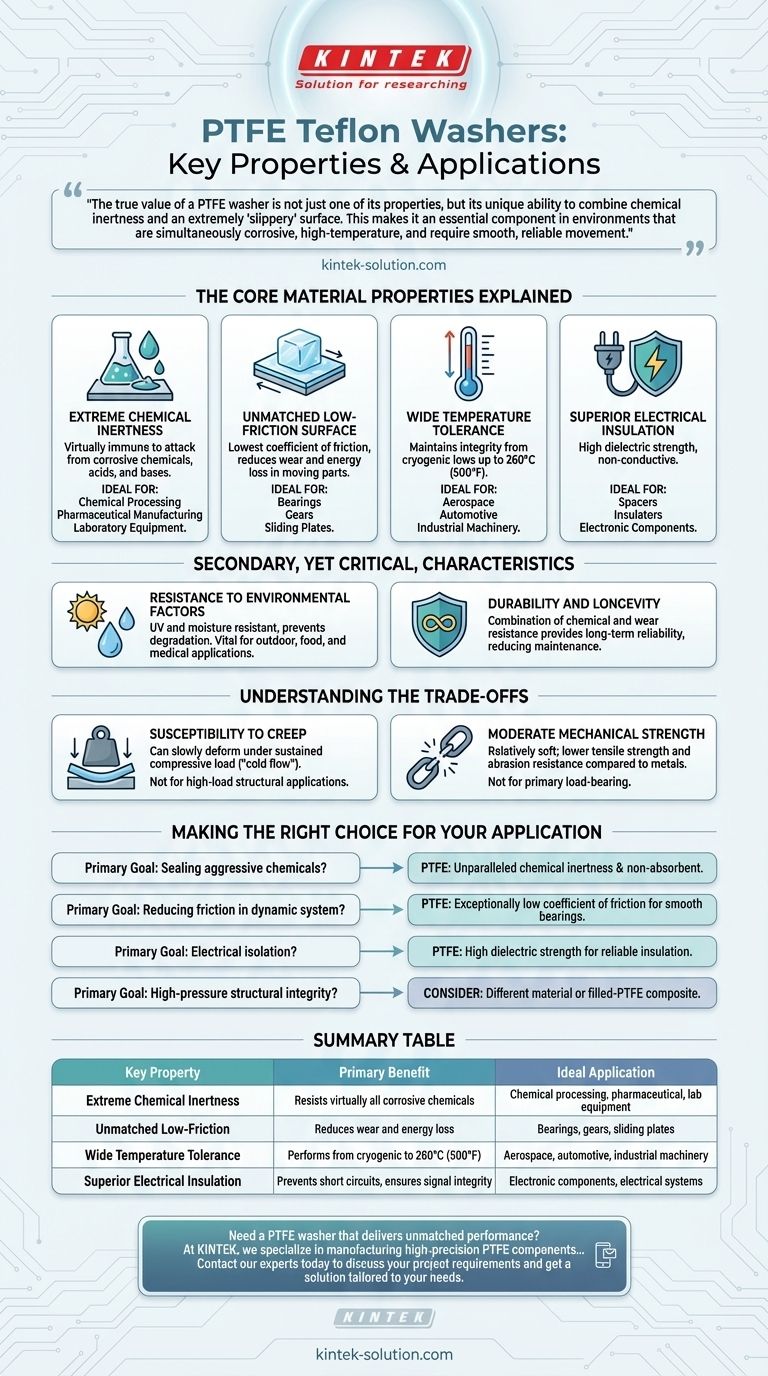

The Core Material Properties Explained

To understand if a PTFE washer is the right component for your project, you must first understand the practical implications of its primary characteristics.

### Extreme Chemical Inertness

PTFE is one of the most non-reactive materials known. It is virtually immune to attack from the vast majority of corrosive chemicals, acids, and bases.

This makes it indispensable for sealing and separating components in chemical processing, pharmaceutical manufacturing, and laboratory equipment where material purity and resistance to degradation are critical.

### Unmatched Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent slipperiness means it reduces wear and energy loss in moving parts.

This property is crucial in applications like bearings, gears, and sliding plates, where it allows for smooth, stick-free operation and significantly extends the life of the assembly.

### Wide Temperature Tolerance

These washers maintain their integrity and performance across an exceptionally broad temperature range, typically from cryogenic lows up to around 260°C (500°F).

Unlike many plastics that become brittle in the cold or deform in the heat, PTFE provides a reliable seal and low-friction surface in extreme thermal conditions found in aerospace, automotive, and industrial machinery.

### Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it does not conduct electricity.

This makes it a perfect choice for spacers and insulators in electronic components and electrical systems, preventing short circuits and ensuring signal integrity.

Secondary, Yet Critical, Characteristics

Beyond the primary properties, several other features contribute to PTFE's versatility and reliability.

### Resistance to Environmental Factors

PTFE washers are highly resistant to UV radiation and do not absorb moisture. This prevents them from degrading or changing shape when exposed to sunlight or wet environments.

This durability is vital for outdoor applications and for industries like food processing and medical devices where hygiene is paramount, as the non-absorbent surface resists bacterial growth.

### Durability and Longevity

The combination of chemical resistance and wear resistance from its low-friction nature means PTFE washers are exceptionally durable.

They significantly reduce maintenance needs and replacement frequency, providing long-term reliability in challenging operating conditions.

Understanding the Trade-offs

No material is perfect. While PTFE's properties are remarkable, its limitations are just as important to understand for proper application.

### Susceptibility to Creep

The primary weakness of PTFE is creep, or "cold flow." Under sustained compressive load, especially at elevated temperatures, the material can slowly deform permanently.

This makes pure PTFE washers unsuitable for high-load structural applications where maintaining precise dimensions under constant pressure is essential.

### Moderate Mechanical Strength

Compared to metals or engineering plastics like nylon, PTFE is a relatively soft material. It has lower tensile strength and abrasion resistance.

It is not designed to be a high-strength fastener. It serves best as a seal, a spacer, or a low-friction bearing surface, not as a primary load-bearing component.

Making the Right Choice for Your Application

Selecting the right washer requires aligning the material's strengths with your primary goal.

- If your primary focus is sealing aggressive chemicals or preventing contamination: PTFE is an unparalleled choice due to its chemical inertness and non-absorbent surface.

- If your primary focus is reducing friction in a dynamic system: The exceptionally low coefficient of friction makes PTFE ideal for creating smooth, wear-resistant bearings and sliding surfaces.

- If your primary focus is electrical isolation: PTFE's high dielectric strength provides reliable insulation for sensitive electronic and electrical components.

- If your primary focus is high-pressure structural integrity: You should consider a different material or a filled-PTFE composite, as pure PTFE can creep under high static loads.

Ultimately, understanding both the strengths and weaknesses of PTFE washers empowers you to deploy them where they can deliver maximum performance and reliability.

Summary Table:

| Key Property | Primary Benefit | Ideal Application |

|---|---|---|

| Extreme Chemical Inertness | Resists virtually all corrosive chemicals | Chemical processing, pharmaceutical, lab equipment |

| Unmatched Low-Friction | Reduces wear and energy loss | Bearings, gears, sliding plates |

| Wide Temperature Tolerance | Performs from cryogenic to 260°C (500°F) | Aerospace, automotive, industrial machinery |

| Superior Electrical Insulation | Prevents short circuits, ensures signal integrity | Electronic components, electrical systems |

Need a PTFE washer that delivers unmatched performance in your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a custom prototype or a high-volume order, our expertise ensures you get a component that leverages PTFE's full potential—combining chemical resistance, low friction, and thermal stability for superior reliability.

Contact our experts today to discuss your project requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions