In short, PTFE bellows offer a unique combination of universal chemical resistance, operational purity, and long-term durability. Their non-stick, FDA-compliant surface makes them ideal for sterile applications, while their resilience in corrosive environments reduces maintenance and ensures system longevity.

The core decision to use PTFE bellows is not just about choosing a flexible connector; it is about future-proofing a system against chemical attack and contamination, a capability where PTFE often surpasses traditional materials like metal.

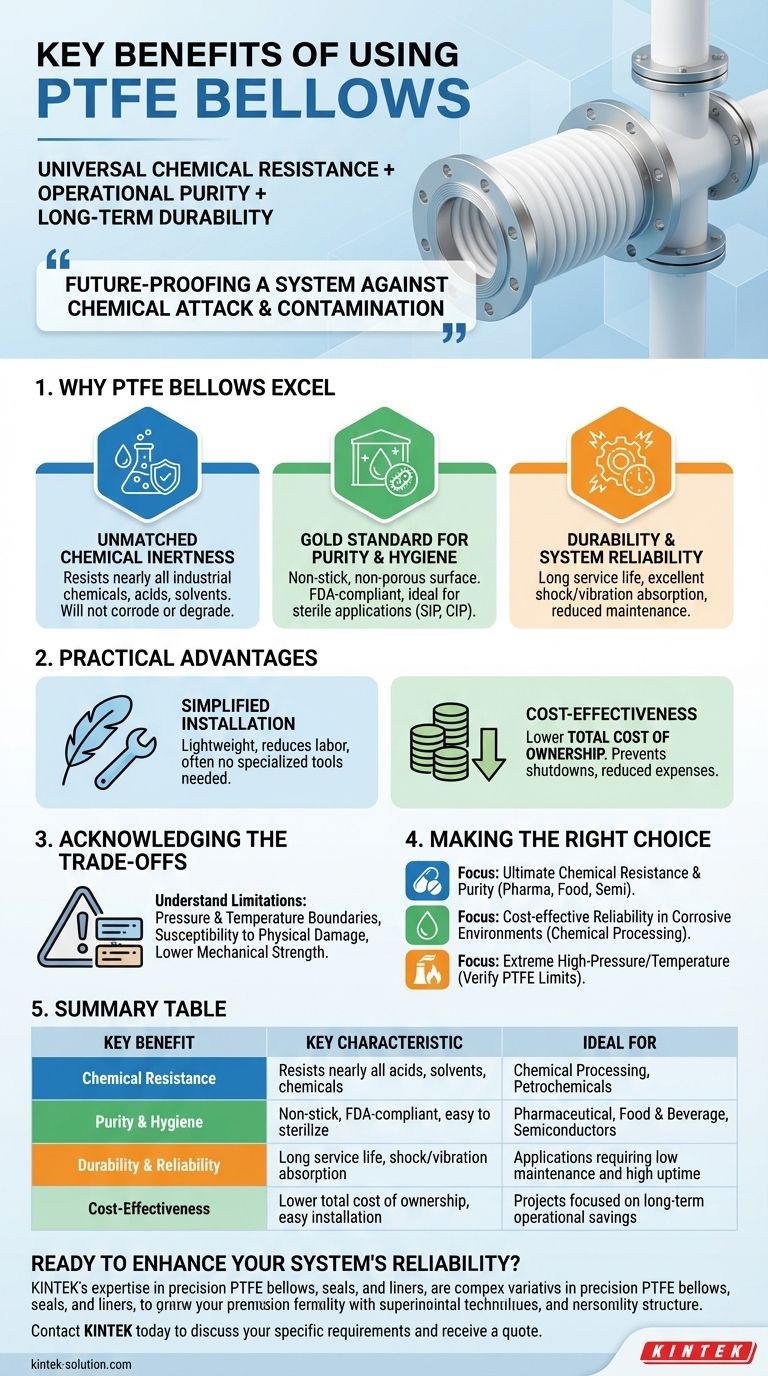

Why PTFE Bellows Excel in Demanding Environments

The value of Polytetrafluoroethylene (PTFE) bellows comes from a set of inherent material properties that solve critical challenges in fluid transfer, system connection, and process protection.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents. This universal chemical resistance means the bellows will not corrode, degrade, or leach contaminants into the process fluid.

This property provides exceptional reliability in industries like chemical processing and petrochemicals, where aggressive media would quickly destroy lesser materials.

The Gold Standard for Purity and Hygiene

PTFE has an exceptionally smooth, non-porous surface that resists adhesion. This non-stick property prevents material buildup, minimizes the risk of blockages, and ensures efficient fluid flow.

Crucially, many grades of PTFE are FDA compliant and suitable for sterilization processes like steam-in-place (SIP) and clean-in-place (CIP). This makes them the default choice for sanitary applications in the pharmaceutical, food and beverage, and semiconductor manufacturing industries.

Durability and System Reliability

PTFE bellows are engineered for a long service life, which significantly reduces maintenance costs and downtime.

They also provide excellent shock and vibration absorption, protecting sensitive equipment and piping systems from mechanical stress. This inherent flexibility and resilience ensure operational stability over time.

Understanding the Practical Advantages

Beyond core material science, PTFE bellows offer significant benefits in installation and overall cost of ownership.

Simplified Installation and Handling

Compared to their metal counterparts, PTFE bellows are extremely lightweight. This drastically simplifies handling and reduces the labor required for installation.

Often, no specialized tools or heavy lifting equipment are needed, making installation faster and more cost-effective.

Cost-Effectiveness Beyond the Initial Price

While the initial component price is a factor, the true economic benefit comes from a lower total cost of ownership.

The combination of a long, low-maintenance lifespan, prevention of costly system shutdowns, and reduced installation expenses makes PTFE bellows a highly economical choice for the right application.

Acknowledging the Trade-offs

No material is perfect for every scenario. To make an informed decision, you must understand the limitations of PTFE.

Pressure and Temperature Boundaries

While PTFE performs well across a wide temperature range, it does not have the same extreme high-temperature and high-pressure capabilities as specialized metal alloys. In applications exceeding PTFE's design limits, a metal bellow may be necessary.

Susceptibility to Physical Damage

PTFE is a durable polymer, but it is softer than metal. It can be more susceptible to puncture or abrasive wear from sharp external objects or highly abrasive slurries. In physically harsh environments, external protection may be required.

Lower Mechanical Strength

PTFE offers excellent flexibility but has lower tensile strength than steel. For applications requiring high rigidity or the management of extreme axial forces, the mechanical properties must be carefully evaluated against the system's demands.

Making the Right Choice for Your Application

Selecting the correct bellow material requires balancing performance needs with operational realities.

- If your primary focus is ultimate chemical resistance and purity (Pharma, Food, Semiconductors): PTFE is almost always the superior choice due to its inertness and non-stick, hygienic surface.

- If your primary focus is cost-effective reliability in a corrosive environment (Chemical Processing, Water Treatment): PTFE offers an outstanding balance of performance, longevity, and total cost of ownership.

- If your primary focus is extreme high-pressure or high-temperature service (Power Generation, Heavy Industry): You must carefully verify that your system's operating parameters are within PTFE's specified limits, considering metal bellows as a potential alternative.

Ultimately, understanding these core benefits and trade-offs empowers you to select the material that ensures the safety, efficiency, and longevity of your system.

Summary Table:

| Key Benefit | Key Characteristic | Ideal For |

|---|---|---|

| Chemical Resistance | Resists nearly all acids, solvents, and chemicals | Chemical Processing, Petrochemicals |

| Purity & Hygiene | Non-stick, FDA-compliant, easy to sterilize | Pharmaceutical, Food & Beverage, Semiconductors |

| Durability & Reliability | Long service life, shock/vibration absorption | Applications requiring low maintenance and high uptime |

| Cost-Effectiveness | Lower total cost of ownership, easy installation | Projects focused on long-term operational savings |

Ready to enhance your system's reliability with high-performance PTFE components?

KINTEK specializes in the precision manufacturing of PTFE bellows, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, ensuring your systems achieve maximum chemical resistance, purity, and longevity.

Contact KINTEK today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key properties of PTFE flange gaskets? Unmatched Chemical & Thermal Resistance

- What role do PTFE gaskets play in the food and beverage industry? Ensuring Purity and Compliance

- How is Teflon parts machining adapting to sustainability goals? Maximize Lifespan & Minimize Waste

- When are filled Teflon back-up rings recommended? Essential for High-Pressure & High-Temperature Seals

- In which applications are PTFE bushings suitable? Ideal for Demanding Chemical, Thermal, and Friction Environments

- What are the three primary application areas for PTFE O-rings? Master Sealing in Harsh Environments

- Why did PTFE seals fall out of favor in the 1950s and 1960s? A Lesson in Material Misunderstanding

- What are the key features of a Lined Plug Valve? Robust Corrosion Resistance & Maximum Flow