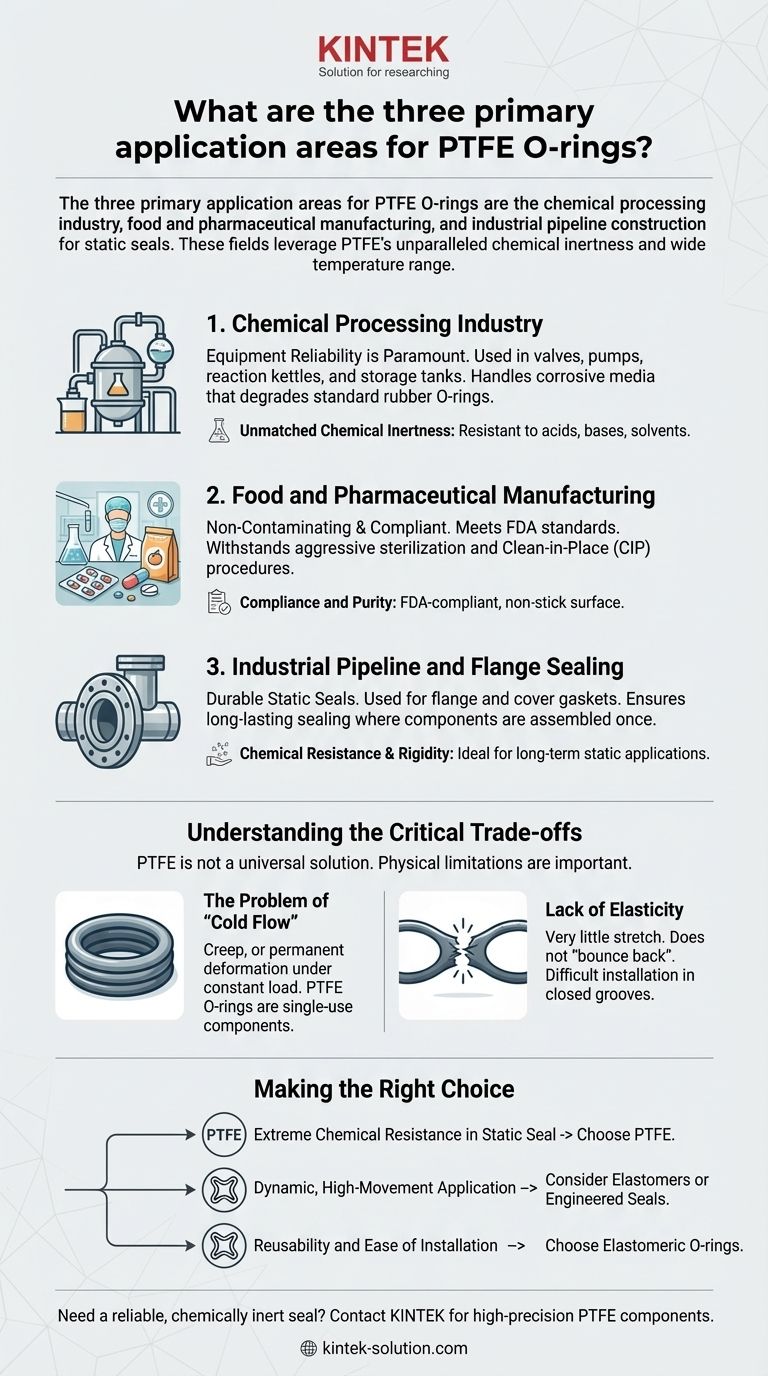

The three primary application areas for PTFE O-rings are the chemical processing industry, food and pharmaceutical manufacturing, and industrial pipeline construction for static seals. These fields specifically leverage PTFE's unparalleled chemical inertness and wide temperature range, properties that are essential for handling aggressive media and stringent cleaning protocols.

The core reason to select a PTFE O-ring is for its near-universal chemical resistance in static applications where traditional elastomers would fail. However, this advantage comes with a critical trade-off: its lack of elasticity and tendency to permanently deform under load.

The Core Properties Defining PTFE Applications

To understand why PTFE (Polytetrafluoroethylene) excels in these specific niches, we must first examine its fundamental material characteristics. These properties directly dictate its ideal use cases.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, and processing agents. This makes it a default choice for equipment that handles a wide variety of corrosive substances.

Wide Operational Temperature Range

With a typical service range from -73°C to 204°C (-100°F to 400°F), PTFE seals can perform reliably in environments with significant temperature fluctuations, from cryogenic processes to high-heat applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a slippery, non-stick surface. This aids in installation and is beneficial in components like bearings or valve seats where low friction is required.

Compliance and Purity

Materials made from virgin PTFE can meet stringent regulatory standards, including FDA compliance. This is non-negotiable for any component that comes into contact with products in the food, beverage, and pharmaceutical industries.

A Deep Dive into Primary Application Areas

These core properties make PTFE the ideal solution for several demanding industrial environments.

The Chemical Processing Industry

In plants manufacturing acids or other harsh chemicals, equipment reliability is paramount. PTFE is used in valves, pumps, reaction kettles, and storage tanks where seals are constantly exposed to corrosive media that would degrade standard rubber O-rings.

Food and Pharmaceutical Manufacturing

This sector requires materials that are both non-contaminating (FDA-compliant) and capable of withstanding aggressive sterilization and clean-in-place (CIP) procedures. PTFE's resistance to caustic cleaning agents and high temperatures makes it perfect for sealing processing equipment.

Industrial Pipeline and Flange Sealing

In pipeline construction, PTFE is often used for static seals like flange and cover gaskets. Its rigidity and chemical resistance ensure a durable, long-lasting seal in applications where the components are assembled once and are not subject to movement.

Understanding the Critical Trade-offs

While its strengths are significant, PTFE is not a universal solution. Its physical limitations are just as important to understand as its chemical advantages.

The Problem of "Cold Flow"

PTFE is not a true elastomer; it does not "bounce back" after being compressed. It exhibits creep, or "cold flow," meaning it will slowly and permanently deform under a constant load. This is why PTFE O-rings are considered single-use components.

Lack of Elasticity

Unlike a rubber O-ring, a solid PTFE O-ring has very little stretch. It cannot be easily installed into closed grooves that require it to be stretched over a diameter. Installation often requires specialized tools or glands with removable access.

Suitability for Static vs. Dynamic Seals

Due to its rigidity and tendency to cold flow, solid PTFE O-rings are overwhelmingly recommended for static (non-moving) applications. While PTFE is used in dynamic seals like piston rings, these are typically engineered designs, not simple O-rings.

Making the Right Choice for Your Seal

Selecting the correct sealing material requires balancing chemical resistance, temperature performance, and mechanical properties.

- If your primary focus is extreme chemical resistance in a static seal: PTFE is an excellent and often necessary choice.

- If your primary focus is a dynamic, high-movement application: A standard PTFE O-ring is unsuitable; consider elastomers or specially engineered PTFE-based seals.

- If your primary focus is reusability and ease of installation in a closed groove: PTFE's single-use nature and rigidity make elastomeric O-rings (like FKM or EPDM) a better choice, provided they meet your chemical compatibility needs.

Understanding these trade-offs ensures you leverage PTFE's unique strengths for the right application, guaranteeing a reliable and safe seal.

Summary Table:

| Application Area | Key PTFE Property Utilized | Common Use Cases |

|---|---|---|

| Chemical Processing Industry | Unmatched Chemical Inertness | Valves, pumps, reaction kettles, storage tanks |

| Food & Pharmaceutical Manufacturing | FDA Compliance & Chemical Resistance | Seals for sterilization and clean-in-place (CIP) systems |

| Industrial Pipeline Construction | Chemical Resistance & Rigidity | Static flange and cover gaskets for long-term sealing |

Need a reliable, chemically inert seal for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication services—from prototypes to high-volume orders—ensure you get a sealing solution that leverages PTFE's unique strengths for your specific environment.

Contact us today to discuss your project and discover how our expertise can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE perform against stainless steel in terms of friction? Discover Unmatched Low-Friction Performance

- What are the symptoms of a leaking PTFE butterfly valve? Identify External & Internal Leaks

- What are the two production methods for PTFE sliding bearing pads? A Guide to Manufacturing Choices

- What are the key properties of PTFE balls? Unmatched Performance for Extreme Industrial Environments

- How do PTFE expansion bellows comply with industry standards? Ensuring Safety and Performance

- How does the low friction property of PTFE rotary shaft seals benefit machinery? Boost Efficiency & Reliability

- What are the benefits of using Teflon sheets in heat press machines? Achieve Flawless Transfers & Protect Your Equipment

- What are the benefits of using PTFE PCB material? Achieve Superior High-Frequency Performance & Reliability