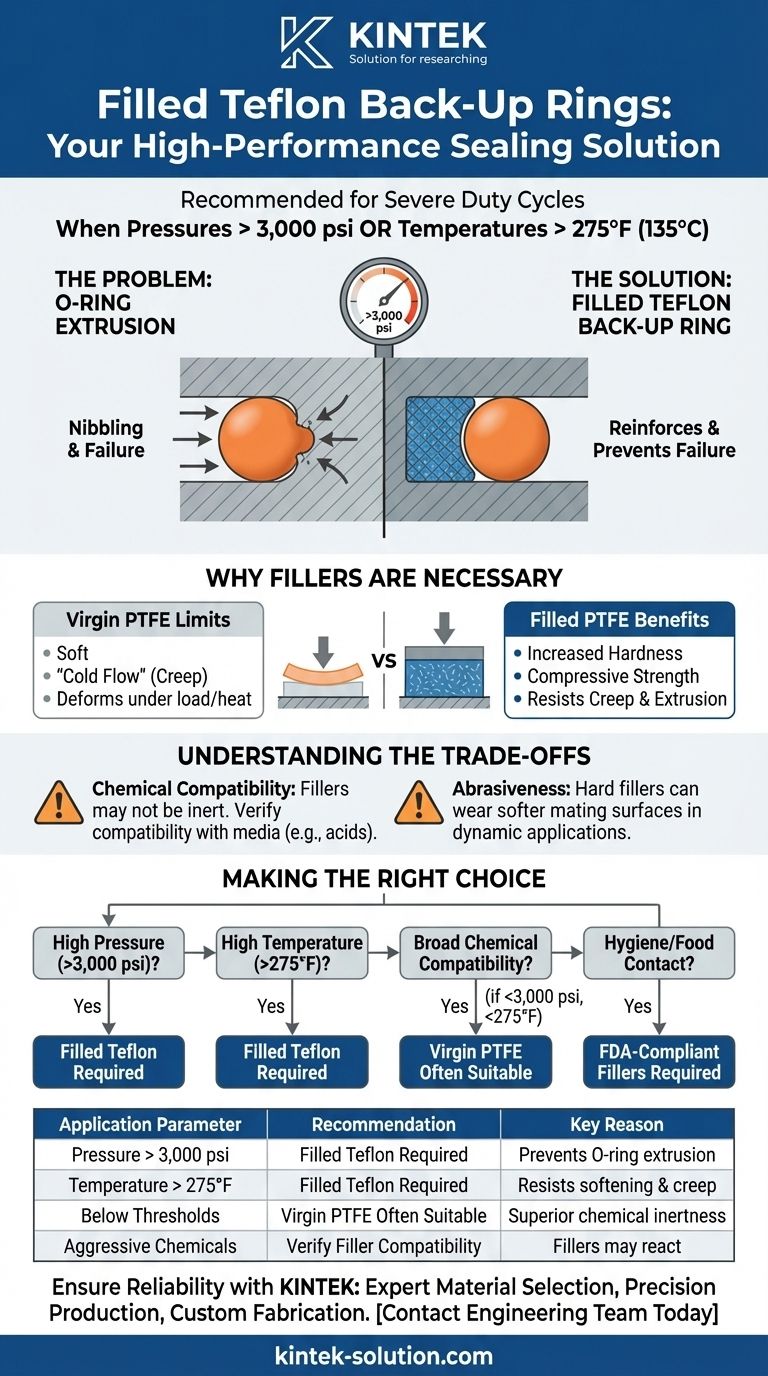

To be direct, filled Teflon back-up rings are the required choice for high-performance sealing applications involving severe duty cycles. They are specifically recommended for systems where pressures exceed 3,000 psi or where operating temperatures consistently rise above 275°F (135°C). Under these demanding conditions, the fillers provide the necessary structural integrity that standard, unfilled Teflon lacks.

The core decision to use a filled Teflon back-up ring is not about chemical compatibility, but about mechanical strength. When high pressure or temperature threatens to physically deform and extrude a seal, fillers act as a reinforcing skeleton within the Teflon, preserving the integrity of the entire sealing system.

The Fundamental Role of a Back-Up Ring

To understand why fillers are necessary, we must first understand the problem that all back-up rings are designed to solve: o-ring extrusion.

What is O-Ring Extrusion?

An o-ring creates a seal by being compressed into a groove between two mating surfaces. However, a small clearance gap, known as the extrusion gap, always exists between these surfaces.

Under high pressure, the relatively soft o-ring material is forced toward this gap. If the pressure is great enough, the o-ring will be pushed into the gap, causing it to be nibbled, sheared, and ultimately fail.

How a Back-Up Ring Prevents Failure

A back-up ring is a thin, hard ring installed in the groove alongside the o-ring, typically on the low-pressure side.

It is made of a much harder, more extrusion-resistant material than the o-ring. Its purpose is to physically block the extrusion gap, providing rigid support and preventing the o-ring from being pushed into it.

When Standard Teflon Is Not Enough

While standard, unfilled Teflon (PTFE) is an excellent material for many back-up rings due to its low friction and chemical inertness, it has mechanical limitations.

The Limits of Virgin PTFE

Virgin PTFE is a relatively soft polymer. Under sustained load and elevated temperatures, it is susceptible to "cold flow" or creep—a slow, continuous deformation.

In a sealing application, this means that a standard Teflon back-up ring can itself begin to deform and extrude into the clearance gap, defeating its purpose and leading to o-ring failure.

The Thresholds for Reinforcement

The industry-recognized thresholds of 3,000 psi and 275°F represent the point where the risk of virgin PTFE deforming becomes unacceptably high.

Above these limits, the material softens and loses the compressive strength needed to bridge the extrusion gap effectively, especially during severe or rapid pressure cycles.

How Fillers Enhance Performance

Adding a filler material to the PTFE base fundamentally changes its mechanical properties, transforming it into a high-performance composite.

Increasing Hardness and Compressive Strength

Fillers such as glass fibers, Nylon, or other specialized polymers are blended into the Teflon matrix. These materials are significantly harder and more rigid than the PTFE itself.

This creates a composite material with vastly improved hardness and compressive strength, much like adding rebar to concrete.

Improving Creep and Extrusion Resistance

The primary benefit of this added strength is a dramatic increase in the material's resistance to creep and extrusion.

A filled Teflon back-up ring can withstand extreme pressures and temperatures without deforming, ensuring the extrusion gap remains securely blocked and the o-ring remains protected.

Understanding the Trade-offs

While fillers provide essential mechanical benefits, they are not a universal upgrade. They introduce trade-offs that must be considered.

Compromised Chemical Inertness

The primary appeal of virgin Teflon is its near-universal chemical resistance. However, the filler material may not share this property.

Using a glass-filled ring in a system with hydrofluoric acid, for example, would result in the acid attacking the glass filler, leading to material failure. You must ensure both the PTFE and the filler are compatible with your system's media.

Potential for Abrasiveness

Hard fillers, particularly glass fibers, can be abrasive to softer mating surfaces like aluminum or brass.

In dynamic applications with frequent movement, a filled back-up ring could cause premature wear on the hardware. This is a critical consideration in systems like hydraulic cylinders or rotating shafts.

Making the Right Choice for Your Application

Your decision should be based on a clear understanding of your system's operating parameters.

- If your primary focus is high-pressure hydraulics (>3,000 psi): A filled Teflon back-up ring is essential to prevent seal extrusion and ensure system reliability.

- If your primary focus is high-temperature stability (>275°F): The enhanced thermal properties of filled Teflon are required to stop the back-up ring from softening and failing under load.

- If your primary focus is broad chemical compatibility in a standard system: Virgin Teflon is often the safer, more reliable choice, provided your pressure and temperature are within its limits.

- If your primary focus is hygiene and compliance (food/beverage): You must select a system with FDA-compliant fillers and ensure they do not introduce abrasive wear that could contaminate the product.

Choosing the right back-up ring is a critical step in designing a robust and reliable sealing system.

Summary Table:

| Application Parameter | Recommendation | Key Reason |

|---|---|---|

| Pressure > 3,000 psi | Filled Teflon Required | Prevents o-ring extrusion under extreme force. |

| Temperature > 275°F (135°C) | Filled Teflon Required | Resists softening and creep (cold flow). |

| Pressure & Temp Below Thresholds | Virgin PTFE Often Suitable | Offers superior chemical inertness when strength isn't critical. |

| Aggressive Chemicals Present | Verify Filler Compatibility | Fillers may not share PTFE's chemical resistance. |

Ensure Your Sealing System's Reliability with KINTEK

Designing for high-pressure hydraulics or extreme temperatures? The right back-up ring is critical to prevent costly seal failure. KINTEK specializes in manufacturing precision PTFE components, including custom filled Teflon back-up rings engineered for severe-duty cycles in the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Material Selection: Guidance on the optimal filler (glass, Nylon, etc.) for your specific pressure, temperature, and chemical environment.

- Precision Production: Components that deliver the exact hardness and compressive strength your application demands.

- Custom Fabrication: From prototype to high-volume orders, ensuring a perfect fit and function.

Don't let a weak link compromise your system. Contact our engineering team today for a consultation and quote on reliable, high-performance sealing solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance