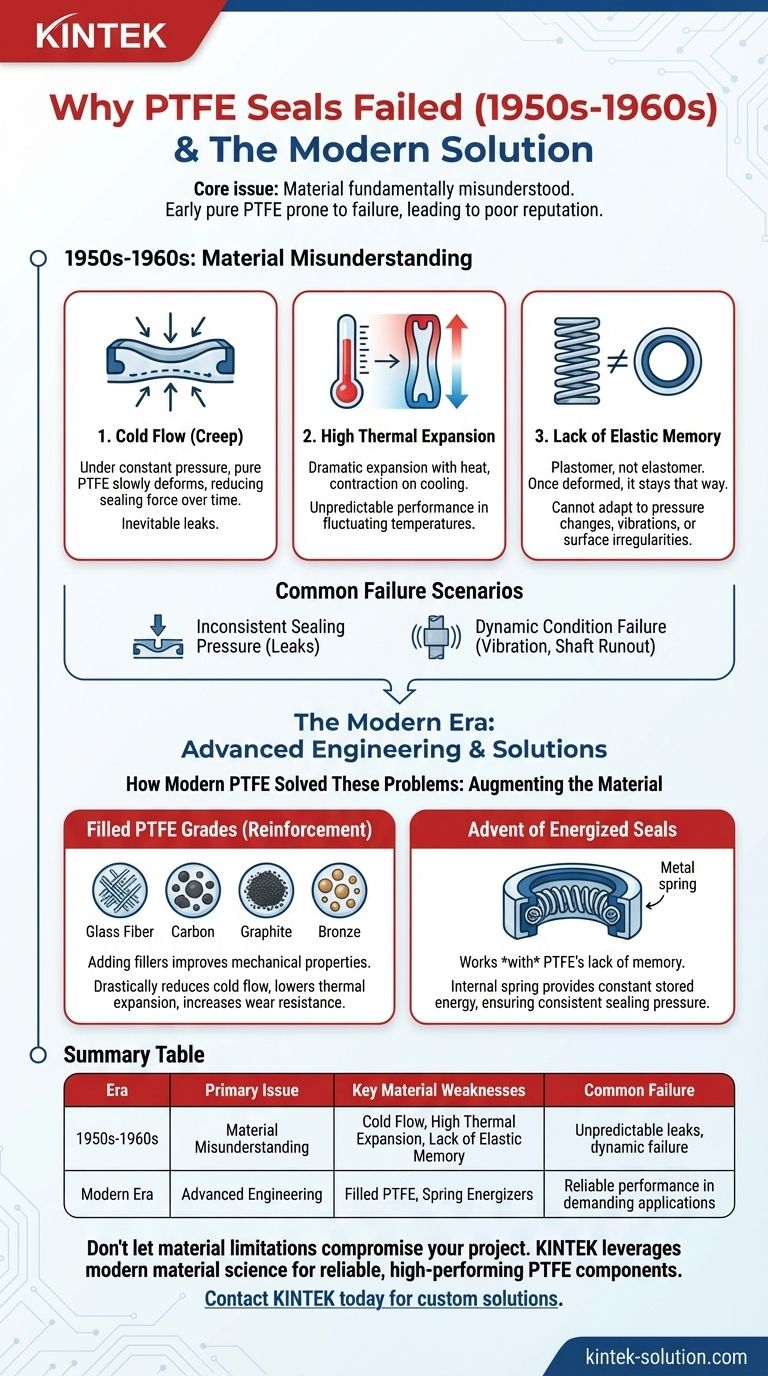

In short, PTFE seals fell out of favor in the 1950s and 1960s because the material was fundamentally misunderstood. Early formulations of pure, unfilled PTFE were prone to failure in many common applications due to inherent material properties that engineers were not yet equipped to manage, leading to a widespread reputation for unreliability.

The core issue was not that PTFE was a poor material, but that its unique characteristics—specifically cold flow, high thermal expansion, and a lack of elastic memory—were a terrible match for the design principles and expectations established for traditional rubber seals.

The Core Technical Challenges of Early PTFE

Engineers initially viewed PTFE (polytetrafluoroethylene) as a "miracle plastic" due to its incredible chemical inertness and low friction. However, applying it as a direct replacement for elastomeric (rubber) seals revealed its significant weaknesses.

The Problem of Cold Flow (Creep)

Cold flow, or creep, is the tendency of a solid material to deform permanently under persistent stress. Early PTFE seals exhibited this trait significantly.

Under the constant pressure required to maintain a seal, the pure PTFE material would slowly "flow" or deform out of its intended shape. This process would reduce the sealing force over time, inevitably leading to leaks.

High Thermal Expansion

PTFE has a coefficient of thermal expansion much higher than that of metals and even most other plastics. This created major problems in applications with fluctuating temperatures.

As a system heated up, the PTFE seal would expand dramatically, increasing stress on the housing and itself. When the system cooled, the seal would contract, often losing its sealing pressure entirely and creating a leak path. This made performance unpredictable in engines and industrial machinery.

Lack of Elastic Memory

Unlike rubber, which is an elastomer, PTFE is a plastomer. This is the most critical distinction.

Elastomers are "springy" and will return to their original shape after being compressed. This elasticity allows them to compensate for minor imperfections in metal surfaces and maintain a consistent sealing force.

Pure PTFE has virtually no elastic memory. Once compressed or deformed, it stays that way. It could not adapt to pressure changes, vibrations, or surface irregularities, making it a brittle and unforgiving sealing solution.

Common Failure Scenarios of the Era

These material properties didn't just exist in a lab; they caused predictable and frustrating failures in the field, cementing the material's poor reputation.

Inconsistent Sealing Pressure

The combination of cold flow and thermal expansion meant that the sealing pressure was never stable. An engineer could install a seal to perfect specifications, only to have it fail days or weeks later as the material crept or after a few temperature cycles.

Inability to Handle Dynamic Conditions

While modern PTFE is used in dynamic seals, the early pure versions were unsuitable. They could not tolerate the shaft runout, vibration, and pressure fluctuations common in rotating or reciprocating equipment, as their lack of elasticity prevented them from maintaining contact with the moving surface.

The Rise of More Forgiving Alternatives

During this same period, advances in synthetic rubbers like Viton™ (FKM) provided engineers with reliable, high-performance elastomeric options. These materials offered good chemical resistance and a wide temperature range while behaving in a predictable, elastic manner that designers understood well.

How Modern PTFE Solved These Problems

The reputation of PTFE seals was rehabilitated not by changing the fundamental polymer, but by learning how to augment it. The solution was the development of filled PTFE grades.

The Role of Reinforcing Fillers

Engineers discovered that adding fillers like glass fiber, carbon, graphite, or bronze to the raw PTFE dramatically improved its mechanical properties.

These fillers act as a reinforcing matrix within the plastic. They drastically reduce cold flow, lower the coefficient of thermal expansion to be more compatible with metals, and increase wear resistance.

The Advent of Energized Seals

Designers also learned to work with PTFE's lack of memory instead of against it. The modern PTFE seal often incorporates a metal spring (an "energizer") inside the seal jacket.

This spring provides the constant, stored energy that the PTFE material itself lacks, ensuring the seal lips maintain consistent pressure against the sealing surface regardless of temperature, pressure, or minor wear.

Applying the Lessons of Early PTFE

Understanding this history helps in selecting the right material today. The fundamental properties of PTFE haven't changed, but our engineering solutions have.

- If your primary focus is static chemical resistance: A pure, virgin-grade PTFE can still be an excellent choice for gaskets where temperatures are stable and clamping force can be periodically re-torqued.

- If you need to seal in a high-pressure or high-temperature dynamic system: A modern, filled PTFE grade with a spring energizer is almost certainly the correct approach, as it's designed to mitigate the historical failure modes.

- If your application requires high elasticity to absorb vibration or misalignment: An elastomeric material like FKM or silicone might be a more forgiving and reliable choice than any grade of PTFE.

Ultimately, the story of early PTFE seals is a crucial lesson in engineering: success depends not on finding a "perfect" material, but on deeply understanding a material's inherent limitations and designing a system that compensates for them.

Summary Table:

| Era | Primary Issue | Key Material Weaknesses | Common Failure |

|---|---|---|---|

| 1950s-1960s | Material Misunderstanding | Cold Flow (Creep), High Thermal Expansion, Lack of Elastic Memory | Unpredictable leaks, inability to handle dynamic conditions |

| Modern Era | Advanced Engineering | Filled PTFE Grades (Glass, Carbon, Bronze), Spring Energizers | Reliable performance in demanding applications |

Don't let material limitations compromise your project. The history of PTFE teaches us that success lies in expert application. At KINTEK, we specialize in precision PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. We leverage modern material science—including filled compounds and custom designs—to overcome the very challenges that plagued early engineers. Whether you need prototypes or high-volume production, our expertise ensures your PTFE solution is reliable and high-performing. Contact KINTEB today to discuss your specific requirements and get a custom solution that works.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions