The primary advantages of PTFE O-rings are their near-universal chemical inertness, exceptionally wide operating temperature range, and extremely low coefficient of friction. These properties make Polytetrafluoroethylene (PTFE) a premier choice for sealing applications in environments that would destroy conventional elastomeric materials like rubber.

PTFE is not a direct replacement for a standard rubber O-ring; it is a specialized problem-solver. Its core strengths in chemical, thermal, and friction resistance are balanced by its relative rigidity, a critical factor that must be accounted for in design.

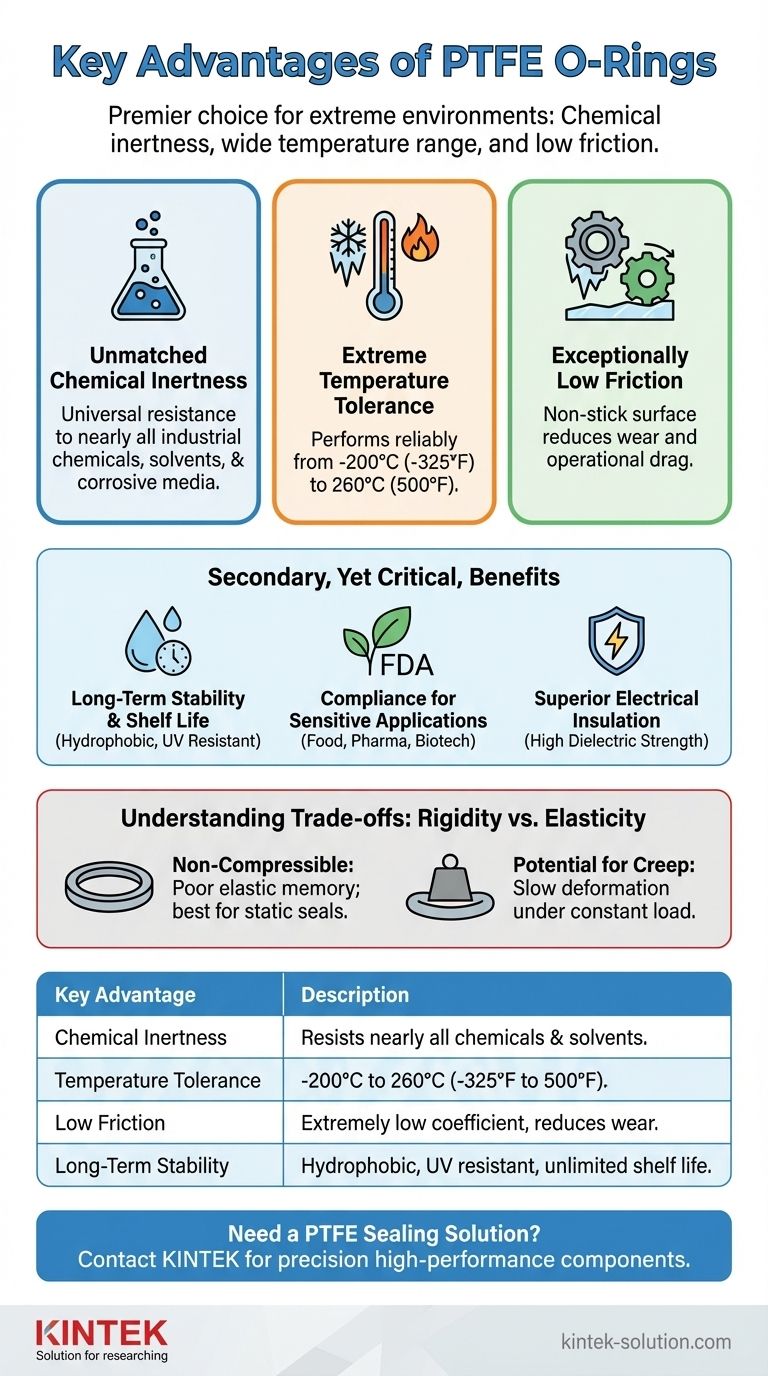

The Core Strengths of PTFE

PTFE's unique molecular structure, composed of strong carbon-fluorine bonds, is the source of its most powerful and sought-after characteristics.

Unmatched Chemical Inertness

PTFE offers universal resistance to nearly all industrial chemicals, solvents, and corrosive media. This makes it an essential material for applications in chemical processing, pharmaceuticals, and aerospace.

Unlike elastomers that can swell, degrade, or dissolve when exposed to aggressive substances, PTFE remains stable and effective, ensuring seal integrity.

Extreme Temperature Tolerance

PTFE O-rings perform reliably across a vast temperature spectrum, from cryogenic conditions around -325°F (-200°C) up to high heat applications of 500°F (260°C).

This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures, a common failure point for many other sealing materials.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This property is invaluable in both static and dynamic applications.

Its non-stick, "slippery" surface reduces wear on moving parts, prevents stick-slip issues in machinery, and lowers the energy required for operation.

Secondary, Yet Critical, Benefits

Beyond the primary advantages, PTFE provides several other properties that enhance its value in demanding situations.

Long-Term Stability and Shelf Life

PTFE is hydrophobic, meaning it does not absorb water and will not swell. It is also highly resistant to UV radiation and weathering, giving it a virtually unlimited shelf life and excellent performance in outdoor applications.

Compliance for Sensitive Applications

The inherent purity and non-toxic nature of PTFE often make it compliant with FDA regulations. This positions it as a go-to material for the food, beverage, and pharmaceutical industries where contamination is not an option.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator, maintaining high dielectric strength across a wide range of temperatures and frequencies. This makes it suitable for sealing components in electrical equipment and connectors.

Understanding the Trade-offs: Rigidity vs. Elasticity

Choosing PTFE requires an understanding of its mechanical limitations. It is a fluoroplastic, not an elastomer, and this distinction is crucial for successful implementation.

The Challenge of Non-Compressibility

Unlike a rubber O-ring that seals by being squeezed and deforming, a pure PTFE O-ring is relatively rigid and non-compressible. It has poor elastic memory, meaning it does not readily "bounce back" to its original shape after a compressive force is removed.

This means it is best suited for static face seals or applications where the hardware design can compensate for its lack of elasticity.

Potential for Creep

Under a constant compressive load, especially at elevated temperatures, PTFE can be subject to creep, or cold flow. This is a slow, permanent deformation of the material that can eventually lead to a loss of sealing force.

Sealing Effectiveness

Because of its rigidity, a PTFE O-ring may not conform to surface imperfections as effectively as a flexible elastomer. This can make achieving a perfect seal more challenging, particularly in low-pressure systems.

When to Choose a PTFE O-ring

Your application's specific demands will determine if PTFE is the right material. Use these guidelines to make an informed decision.

- If your primary focus is aggressive chemical exposure: PTFE provides a nearly universal solution where other materials would quickly degrade.

- If your application involves extreme temperatures (high or cryogenic): PTFE maintains its structural and sealing integrity across a vast thermal range.

- If you need a low-friction seal for a static or slow-moving part: PTFE's slick surface prevents stick-slip, reduces wear, and minimizes operational drag.

- If you require a resilient, forgiving seal for a dynamic application: You should consider a standard elastomeric O-ring or an energized PTFE seal, which incorporates a spring to provide the necessary elasticity.

Ultimately, selecting the correct sealing material is about aligning its unique properties with the specific challenges of your environment.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, solvents, and corrosive media. |

| Temperature Tolerance | Performs reliably from -200°C (-325°F) to 260°C (500°F). |

| Low Friction | Extremely low coefficient of friction, reducing wear and energy use. |

| Long-Term Stability | Hydrophobic, UV resistant, and offers a virtually unlimited shelf life. |

Need a PTFE Sealing Solution for Your Demanding Application?

PTFE O-rings are the premier choice for extreme environments in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom O-rings, seals, liners, and labware.

We work with you from prototype to high-volume production to ensure a perfect fit and superior performance, addressing critical factors like rigidity and creep for your specific application.

Contact KINTEK today to discuss your project requirements and discover how our PTFE expertise can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications