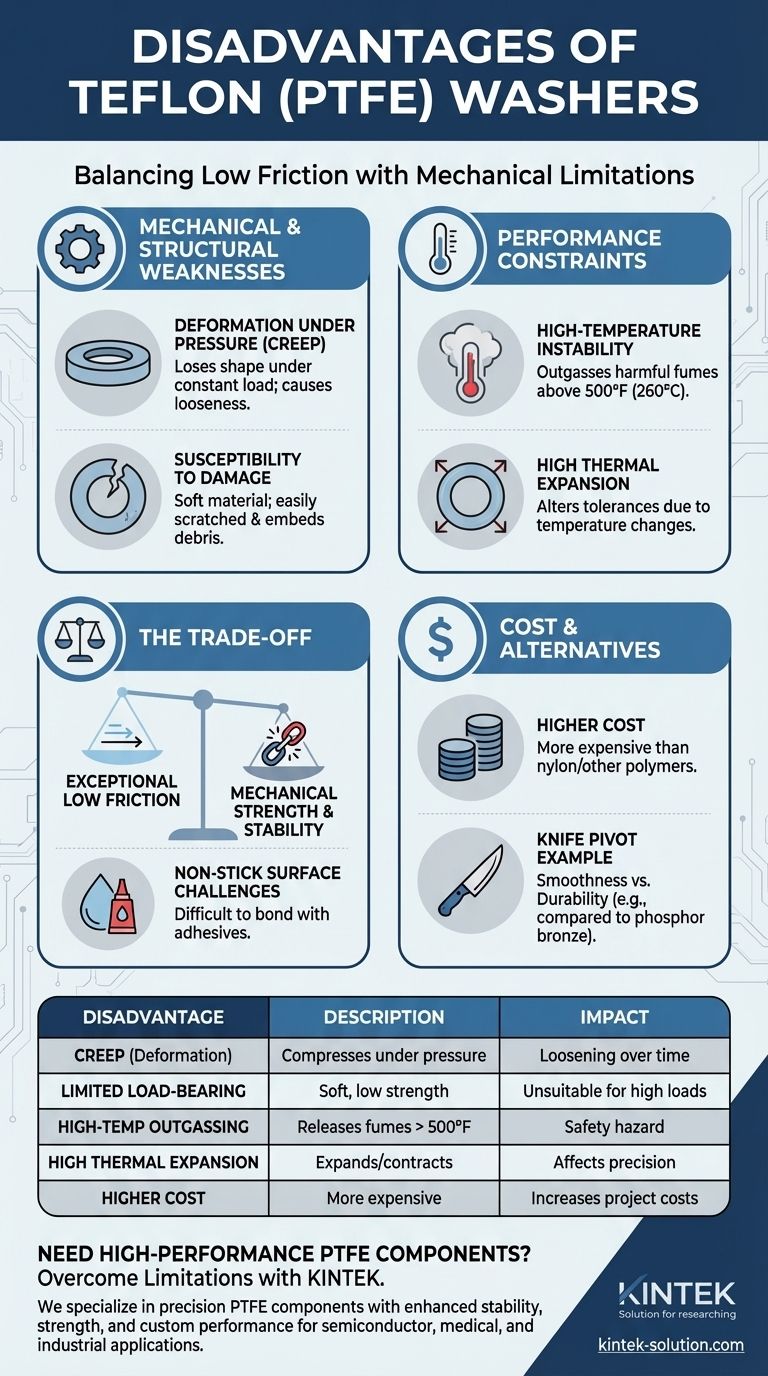

The primary disadvantages of Teflon washers are their tendency to deform under pressure, limited load-bearing strength, potential to release harmful fumes at high temperatures, and relatively high cost compared to other non-metallic options. While prized for their low friction, their lack of mechanical rigidity makes them unsuitable for applications requiring long-term dimensional stability under load.

The core trade-off with Teflon (PTFE) is sacrificing mechanical strength and stability for exceptional low-friction and chemical resistance. Its softness makes it prone to wear and deformation in demanding physical applications.

Mechanical and Structural Limitations

While Teflon's slipperiness is a major advantage, its physical structure presents several significant drawbacks in mechanical assemblies.

Deformation Under Pressure (Creep)

Teflon has very little elasticity. This means that when subjected to consistent pressure over time, it doesn't spring back to its original shape.

This phenomenon, known as creep, causes the washer to slowly compress or deform. In applications like knife pivots, this can lead to looseness or side-to-side "blade play" developing over time.

Susceptibility to Physical Damage

Teflon is a relatively soft material. This makes it easy to scratch, tear, or damage during installation or use.

Furthermore, small bits of debris, like metal shavings from manufacturing, can become embedded in the soft surface of the washer. This embedded debris is difficult to remove and can accelerate wear on adjacent metal parts.

Limited Load-Bearing Capacity

The inherent softness and tendency to deform make Teflon washers a poor choice for high-load or structural applications.

They lack the strength and rigidity of metallic washers like phosphor bronze and are not intended to support significant weight or force.

Performance and Environmental Constraints

Beyond physical strength, Teflon's performance is limited by its reaction to its environment, particularly temperature.

High-Temperature Instability

While Teflon is known for its general heat resistance, it begins to outgas (release fumes) at temperatures around 500°F (260°C). These fumes can be harmful to humans.

This makes it unsuitable for applications where it might be exposed to extreme temperatures, creating a critical safety limitation.

High Thermal Expansion

Teflon has a high coefficient of thermal expansion, meaning it expands and contracts with temperature changes more than most plastics and metals.

In precision assemblies, this can alter tolerances and affect the performance and fit of components as temperatures fluctuate.

Poor Radiation Resistance

Teflon is known to degrade when exposed to high levels of radiation. This is a niche but critical disadvantage in specific industrial, aerospace, or nuclear applications.

Understanding the Trade-offs

Choosing a washer material requires balancing competing priorities. Teflon excels in some areas at the direct expense of others.

Cost vs. Other Non-Metallics

Due to its unique properties and manufacturing process, Teflon is often more expensive than other non-metallic washer materials like nylon. This cost must be justified by the specific need for its low-friction or chemical-resistant properties.

The Knife Pivot Example: Smoothness vs. Durability

In folding knives, Teflon provides a very smooth opening action that requires little to no lubrication.

However, it is seen as less durable than phosphor bronze washers, which resist compression and wear far better, providing a more solid and long-lasting pivot at the cost of requiring occasional lubrication.

Non-Stick Surface Challenges

The very property that makes Teflon useful—its non-stick surface—also makes it difficult to bond to other materials using adhesives. This limits its use in applications where it needs to be fixed in place.

Choosing the Right Washer for Your Application

Ultimately, the suitability of a Teflon washer is defined entirely by the demands of the specific task.

- If your primary focus is ultimate smoothness in a low-load environment: Teflon is a viable choice, particularly where lubrication is undesirable or impractical.

- If your primary focus is long-term durability and load-bearing strength: A metallic washer like phosphor bronze is a mechanically superior option.

- If your primary focus is safety in high-temperature applications: You must respect Teflon's outgassing limits and consider alternatives if temperatures will approach 500°F (260°C).

- If your primary focus is a general-purpose, cost-effective solution: Other polymers may offer a better balance of price and all-around performance.

Matching the material's properties to the application's needs is the key to a successful and reliable design.

Summary Table:

| Disadvantage | Description | Impact |

|---|---|---|

| Creep (Deformation) | Tends to compress and deform under sustained pressure | Leads to loosening and loss of dimensional stability over time |

| Limited Load-Bearing | Soft material with low mechanical strength | Unsuitable for high-load or structural applications |

| High-Temperature Outgassing | Releases harmful fumes above 500°F (260°C) | Creates safety hazards in high-temperature environments |

| High Thermal Expansion | Expands and contracts significantly with temperature changes | Affects precision tolerances in assemblies |

| Higher Cost | More expensive than many alternative non-metallic materials | Increases project costs without mechanical strength benefits |

Need High-Performance PTFE Components That Overcome These Limitations?

At KINTEK, we specialize in manufacturing precision PTFE components that address the common weaknesses of standard Teflon washers. Our expertise in custom fabrication allows us to create solutions with enhanced dimensional stability, improved load-bearing capabilities, and tailored performance characteristics for your specific application.

We serve: Semiconductor, medical, laboratory, industrial, and other specialized industries requiring reliable PTFE components.

Our value: We combine precision production with custom fabrication capabilities—from prototypes to high-volume orders—ensuring your components meet exact mechanical and environmental requirements.

Let us help you optimize your design: Contact our engineering team today to discuss how we can develop PTFE components that deliver both chemical resistance AND mechanical reliability for your critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications