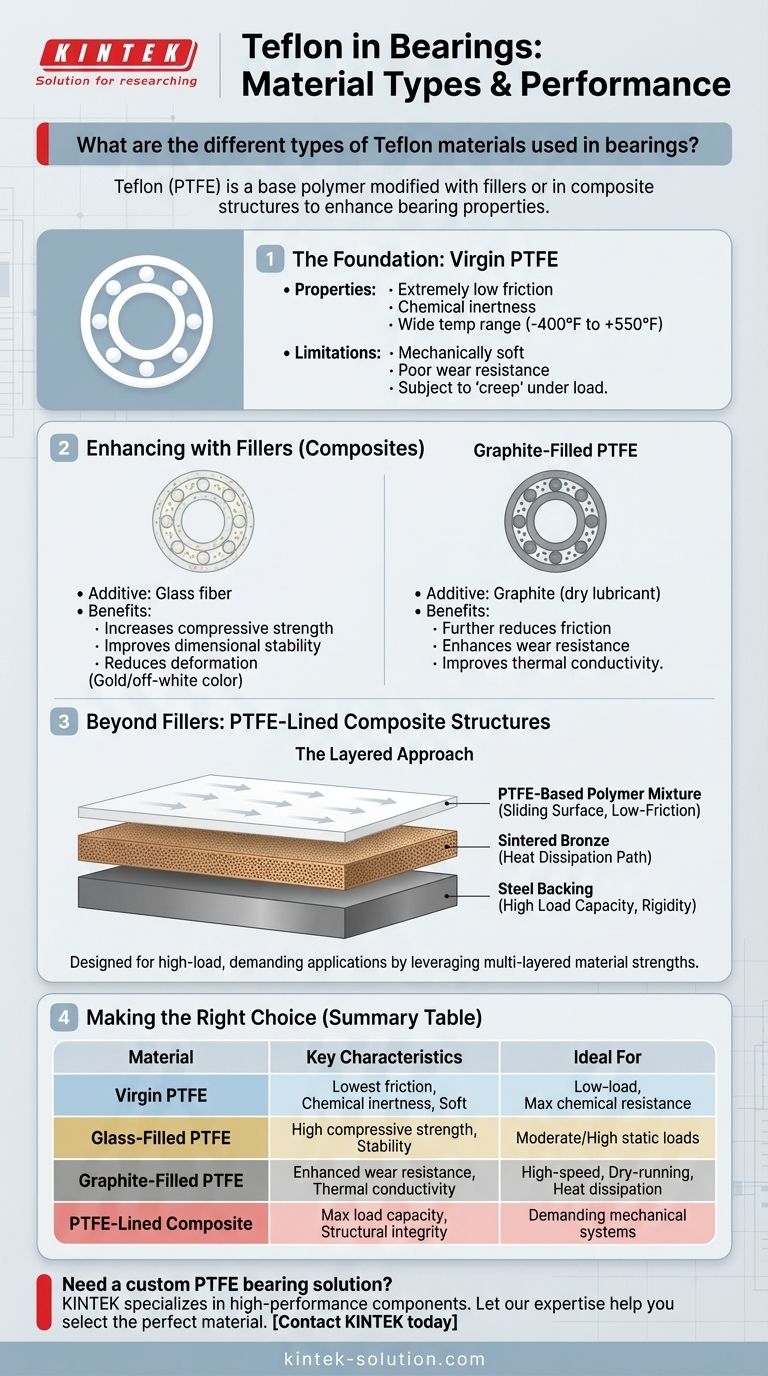

The primary types of Teflon material used in bearings are virgin PTFE, glass-filled PTFE, and graphite-filled PTFE, along with composite structures known as PTFE-lined bearings. Each formulation is engineered to enhance specific properties of the base Polytetrafluoroethylene (PTFE) material, tailoring it for different mechanical and environmental demands.

The core concept to understand is that "Teflon" is not a single material for bearings. It is a base polymer that is intentionally modified with fillers like glass or graphite, or integrated into a metal-backed composite structure, to overcome its natural softness and improve its performance under load.

The Foundation: Virgin PTFE

Core Properties

Virgin Polytetrafluoroethylene (PTFE), the purest form of Teflon, is a white solid known for several exceptional properties.

Its primary benefits are an extremely low coefficient of friction, making it incredibly slick, and near-universal chemical inertness. It also boasts a vast operating temperature range, from -400°F to +550°F (-240°C to +288°C).

Inherent Limitations

Despite these benefits, virgin PTFE is mechanically soft. It has poor wear resistance and can deform under high loads, a phenomenon known as "creep." This makes it unsuitable for most demanding bearing applications on its own.

Enhancing Performance with Fillers

To overcome the mechanical weaknesses of virgin PTFE, manufacturers add filler materials to create stronger, more durable composites.

Glass-Filled PTFE

Glass fiber is a common additive that significantly improves the bearing's properties.

This addition dramatically increases compressive strength and dimensional stability, reducing the material's tendency to deform under load. Glass-filled PTFE is easily identified by its characteristic gold or off-white color.

Graphite-Filled PTFE

Adding graphite to the PTFE matrix serves a dual purpose.

Graphite is a dry lubricant, which reduces the coefficient of friction even further and enhances wear resistance. It also significantly improves thermal conductivity, helping to dissipate heat that can build up in high-speed applications.

Beyond Fillers: Composite Bearing Structures

For high-load applications, a simple filled PTFE is often insufficient. Instead, engineers use multi-layered composite bearings that leverage the strengths of different materials.

The Layered Approach

These bearings typically consist of a steel backing that provides high load capacity and structural rigidity.

Bonded to the steel is a layer of sintered bronze powder. This layer provides a strong mechanical link for the polymer and, crucially, creates a highly effective pathway to conduct heat away from the bearing surface.

The final layer is a PTFE-based polymer mixture that forms the sliding surface. This mixture provides the low-friction, self-lubricating properties Teflon is known for, ensuring smooth, maintenance-free operation.

Understanding the Trade-offs

Selecting the right material requires understanding the compromises inherent in each formulation.

Strength vs. Purity

Fillers enhance mechanical properties like strength and wear resistance, which are critical for a bearing's longevity.

However, adding materials like glass or graphite can slightly reduce the overall chemical resistance of the composite compared to virgin PTFE.

Performance vs. Cost

Virgin PTFE is often the least expensive option but is limited to very light-duty applications.

Filled and composite bearings are highly engineered components designed for specific performance goals. Their advanced construction and superior capabilities come at a higher cost.

Matching Material to Environment

The choice of filler is not arbitrary. A glass-filled bearing excels in stable, high-load scenarios, while a graphite-filled bearing is better suited for high-speed applications where heat dissipation is critical.

Making the Right Choice for Your Application

Your final decision must be driven by the specific demands of your design.

- If your primary focus is chemical compatibility at low loads: Virgin PTFE is a suitable and cost-effective choice.

- If you need to prevent deformation under moderate to high static loads: Glass-filled PTFE provides the necessary dimensional stability and compressive strength.

- If you are dealing with high speeds or dry-running conditions: Graphite-filled PTFE or a PTFE-lined composite bearing is necessary for thermal management and wear resistance.

- If you require maximum load capacity and structural integrity: A steel-backed, PTFE-lined composite bearing is the industry standard for demanding mechanical applications.

Ultimately, choosing the correct Teflon bearing material is about precisely matching the material's engineered properties to the specific challenges of your application.

Summary Table:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| Virgin PTFE | Extreme chemical inertness, lowest friction, but soft with poor wear resistance | Low-load applications requiring maximum chemical resistance |

| Glass-Filled PTFE | High compressive strength, excellent dimensional stability, reduces creep | Moderate to high static load applications |

| Graphite-Filled PTFE | Enhanced wear resistance, superior thermal conductivity, very low friction | High-speed or dry-running conditions where heat dissipation is critical |

| PTFE-Lined Composite | Steel-backed for high load capacity, bronze layer for heat dissipation, PTFE surface for lubrication | Maximum load capacity and structural integrity in demanding mechanical systems |

Need a custom PTFE bearing solution?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and custom bearings. We serve the semiconductor, medical, laboratory, and industrial sectors with precision production and custom fabrication—from prototypes to high-volume orders.

Let our expertise help you select or create the perfect bearing material for your specific load, speed, and environmental requirements. Contact KINTEK today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What standard surface finishes are available for PTFE balls? Tumbled vs. Machined for Optimal Performance

- What materials are used in the construction of PTFE-lined bearings? A Guide to Their 4-Layer Composite Design

- What factors affect the choice between Teflon and parchment for heat pressing? Achieve the Perfect Finish Every Time

- What material can enhance the benefits of ring-type gaskets? Boost Performance with PTFE in Harsh Environments

- What is the high-temperature decomposition method for cleaning Teflon residue? A Guide to High-Risk, High-Efficacy Removal

- What are the two production methods for PTFE sliding bearing pads? A Guide to Manufacturing Choices

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency