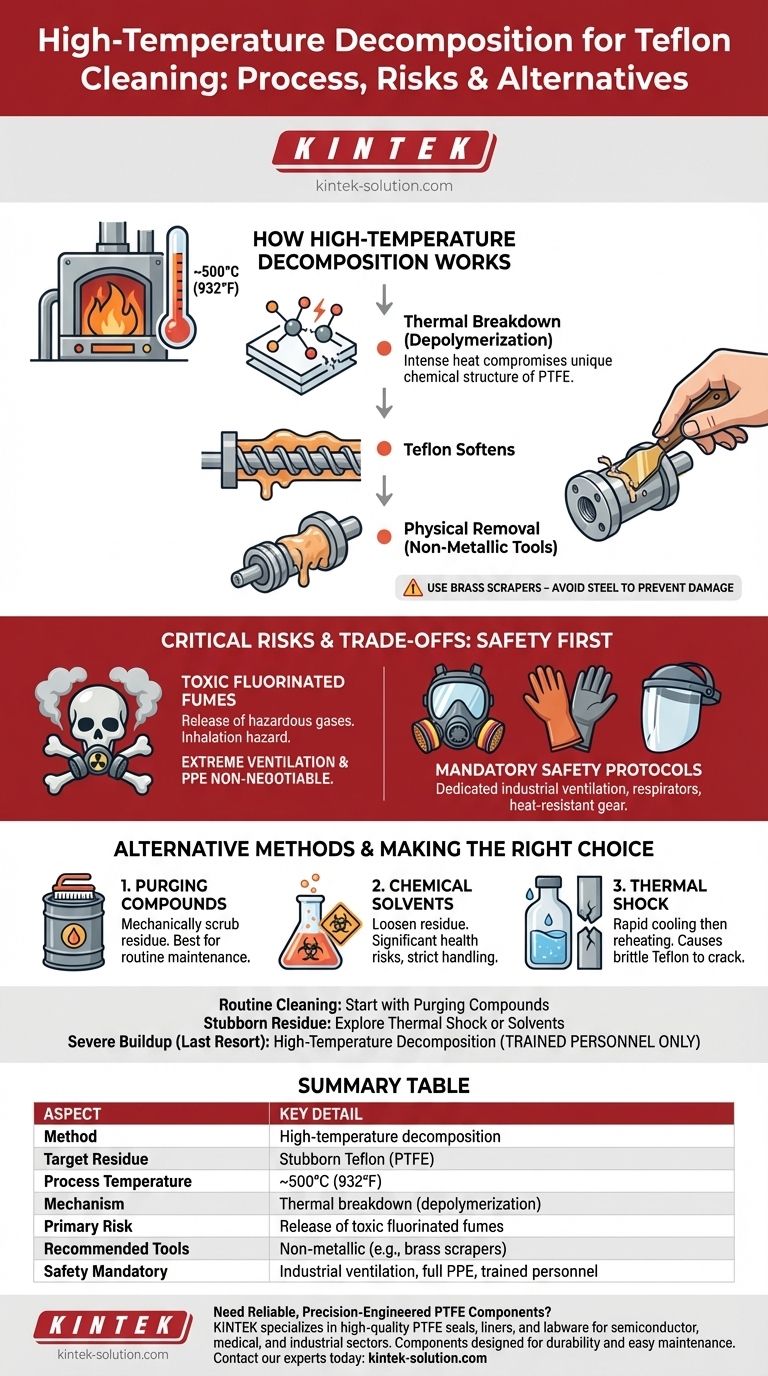

The high-temperature decomposition method is a thermal process for removing stubborn Teflon (PTFE) residue from industrial equipment by heating it to approximately 500°C (932°F). At this temperature, the Teflon softens and begins to break down, allowing it to be physically removed with non-metallic tools like brass scrapers. This method is effective but carries significant safety risks due to the release of toxic fumes.

While heating is a powerful way to break down hardened Teflon, it is a hazardous procedure that must be treated as a last resort. The release of toxic fluorinated compounds at high temperatures makes extreme ventilation and personal protective equipment non-negotiable.

How High-Temperature Decomposition Works

The effectiveness of this method lies in its ability to compromise the unique chemical structure of Teflon (PTFE) through intense heat.

The Principle of Thermal Breakdown

At room temperature, the carbon-fluorine bonds that make up Teflon are exceptionally strong, rendering it inert and non-stick.

Heating the material to around 500°C provides enough energy to begin breaking these bonds. This process, known as depolymerization, causes the tough plastic to lose its structural integrity.

The Softening and Removal Phase

As the Teflon breaks down, it does not melt into a liquid but rather softens into a pliable, gum-like state.

Once softened, the residue can be carefully scraped or brushed away from the surface of the equipment, such as an extruder screw or barrel.

The Importance of Proper Tools

It is critical to use non-metallic tools, such as brass scrapers or brushes, for the removal step.

Using steel or other hard metals can easily scratch, gouge, or otherwise damage the precisely machined surfaces of the equipment, leading to costly repairs and operational issues.

Understanding the Critical Risks and Trade-offs

This method should only be considered when less aggressive options have failed. Its primary drawback is the significant health and safety hazard it creates.

The Hazard of Toxic Fumes

When heated above its decomposition temperature, Teflon releases toxic gases, including various harmful fluorinated compounds.

Inhaling these fumes can cause severe respiratory distress and other serious health problems. This is the single most important factor to consider before attempting this method.

Essential Safety Protocols

This procedure must only be performed in an area with powerful, dedicated industrial ventilation capable of safely capturing and exhausting all fumes.

Operators must be equipped with appropriate Personal Protective Equipment (PPE), including respirators with cartridges rated for acidic gases, heat-resistant gloves, and full-face protection.

Alternative Cleaning Methods

Before resorting to high-temperature cleaning, consider other options:

- Purging Compounds: Specially designed materials that can be run through equipment to mechanically scrub out residue. They can break up Teflon buildup, making final cleaning easier.

- Chemical Solvents: Certain chlorinated solvents or benzene may help loosen residue. However, these chemicals present their own significant health risks and require strict handling protocols.

- Thermal Shock: This involves rapidly cooling the part with liquid nitrogen and then reheating it. The extreme temperature change can cause the brittle Teflon to crack and flake off, making it easier to remove mechanically.

Making the Right Choice for Your Goal

Your approach should be guided by the severity of the residue and your commitment to safety.

- If your primary focus is routine cleaning: Start with the least aggressive methods, such as using a dedicated purging compound during scheduled maintenance.

- If you are dealing with stubborn, localized residue: Explore the thermal shock or chemical solvent methods, but only after conducting a thorough safety assessment.

- If you are facing severe, system-wide buildup where other methods have failed: High-temperature decomposition may be necessary, but it should only be performed by trained personnel with uncompromising safety measures in place.

Choosing the right cleaning method requires balancing operational needs with the absolute priority of protecting your equipment and the health of your team.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Method | High-temperature decomposition |

| Target Residue | Stubborn Teflon (PTFE) |

| Process Temperature | ~500°C (932°F) |

| Mechanism | Thermal breakdown (depolymerization) |

| Primary Risk | Release of toxic fluorinated fumes |

| Recommended Tools | Non-metallic (e.g., brass scrapers) |

| Safety Mandatory | Industrial ventilation, full PPE, trained personnel |

Need reliable, precision-engineered PTFE components that minimize residue buildup? KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. Our components are designed for durability and easy maintenance, reducing the need for aggressive cleaning. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact our experts today to discuss how our PTFE solutions can enhance your operational efficiency and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Cleaning Rack

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments