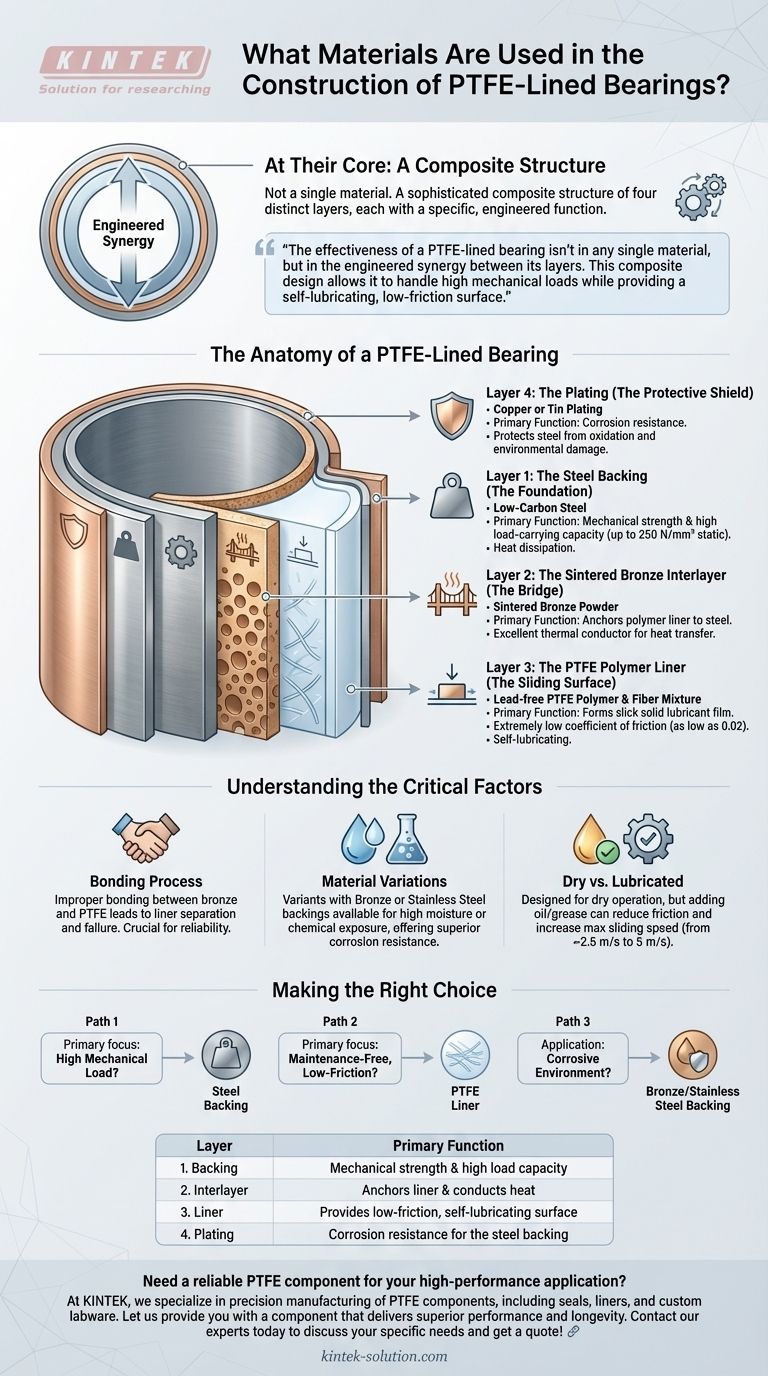

At their core, PTFE-lined bearings are a sophisticated composite structure, not a single material. They are constructed from four distinct layers: a steel backing for strength, a sintered bronze interlayer for thermal conductivity and bonding, a PTFE-based polymer liner for low-friction sliding, and a final plating for corrosion resistance. Each layer performs a specific, engineered function to create a high-performance, self-lubricating system.

The effectiveness of a PTFE-lined bearing isn't in any single material, but in the engineered synergy between its layers. This composite design allows it to handle high mechanical loads while providing a self-lubricating, low-friction surface, often eliminating the need for external grease or oil.

The Anatomy of a PTFE-Lined Bearing

To understand why these bearings are so versatile, we must break down the function of each material layer, starting from the outside and working our way in to the sliding surface.

Layer 1: The Steel Backing (The Foundation)

The outermost layer is typically a low-carbon steel backing.

Its primary role is to provide mechanical strength and high load-carrying capacity. This rigid foundation prevents the bearing from deforming under heavy static (up to 250 N/mm²) or dynamic (up to 140 N/mm²) loads.

The steel also contributes significantly to heat dissipation, drawing thermal energy away from the sliding surface and into the larger housing assembly.

Layer 2: The Sintered Bronze Interlayer (The Bridge)

Bonded to the steel backing is a thin, porous layer of sintered bronze powder.

This layer serves two critical purposes. First, it acts as a strong mechanical bridge, securely anchoring the soft polymer liner to the rigid steel backing.

Second, bronze is an excellent thermal conductor. It plays a crucial role in transferring frictional heat from the PTFE liner to the steel backing, preventing overheating at the surface.

Layer 3: The PTFE Polymer Liner (The Sliding Surface)

This is the innermost layer and the key to the bearing's performance. It is not pure PTFE, but a lead-free polymer and fiber mixture.

During the initial run-in period, a small amount of this material transfers to the mating shaft, forming a very slick solid lubricant film.

This film is what provides the extremely low coefficient of friction (as low as 0.02) and creates the "self-lubricating" property of the bearing.

Layer 4: The Plating (The Protective Shield)

The exterior of the steel backing is coated with a thin plating, typically made of copper or tin.

This final layer has one simple but vital job: corrosion resistance. It protects the steel backing from oxidation and environmental damage, ensuring the structural integrity of the bearing over time.

Understanding the Critical Factors

The material composition is only part of the story. The manufacturing process and material variations are just as important for reliable performance.

The Importance of the Bonding Process

The bond between the sintered bronze and the PTFE liner is a common failure point. Improper bonding can lead to liner separation, causing a rapid increase in friction, degradation, and potential catastrophic failure.

It is critical to select a manufacturer with proven experience in this specific bonding process to ensure reliability and longevity.

Material Variations for Specific Environments

While carbon steel is the standard backing, it's not suitable for every application.

For environments with high moisture or chemical exposure, variants with bronze or stainless steel backings are available. These offer superior corrosion resistance at the cost of potential changes in load capacity or thermal performance.

Dry vs. Lubricated Performance

Although designed for dry operation, these bearings can also be used with external lubrication. Adding oil or grease can further reduce friction and increase the maximum sliding speed from approximately 2.5 m/s to 5 m/s.

Making the Right Choice for Your Application

The specific material construction you need depends entirely on your primary engineering goal.

- If your primary focus is high mechanical load capacity: The carbon steel backing is the critical component, providing the necessary structural strength.

- If your primary focus is maintenance-free, low-friction operation: The PTFE polymer liner, which creates the solid lubricant film, is the key feature.

- If your application is in a corrosive environment: You should specify a bearing with a stainless steel or bronze backing instead of standard plated steel.

Understanding how each material layer contributes to the bearing's overall performance is the first step in selecting the correct component for your design's success.

Summary Table:

| Layer | Material | Primary Function |

|---|---|---|

| 1. Backing | Low-Carbon Steel | Mechanical strength & high load capacity |

| 2. Interlayer | Sintered Bronze | Anchors liner & conducts heat |

| 3. Liner | PTFE Polymer Mixture | Provides low-friction, self-lubricating surface |

| 4. Plating | Copper or Tin | Corrosion resistance for the steel backing |

Need a reliable PTFE component for your high-performance application?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including seals, liners, and custom labware. Our expertise in material science and fabrication ensures that every part, from prototypes to high-volume orders, meets the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

Let us provide you with a component that delivers superior performance and longevity. Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the two main methods for producing PTFE? Choose the Right Path for Your Application

- What are the key advantages of PTFE-jacketed spring energized seals? Unlock Unmatched Sealing Performance

- What electrical properties do PTFE mechanical seals possess? Superior Insulation for Demanding Applications

- In which applications are anti-static PTFE bellows used? Essential for Static-Sensitive Industries

- What makes PTFE rod ideal for use in the chemical industry? Ensure Unmatched Corrosion Resistance

- What chemical solvents can be used to clean Teflon residue? The Safer, More Effective Alternatives

- Why are spring-energized PTFE seals suitable for the aerospace industry? Unmatched Reliability in Extreme Conditions

- How does the low friction coefficient of PTFE coatings affect tightening torque? Achieve Accurate Clamping Force Safely